| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Ultrasonic Cleaning Equipment |

|---|---|

| Brand Name: | Jietai |

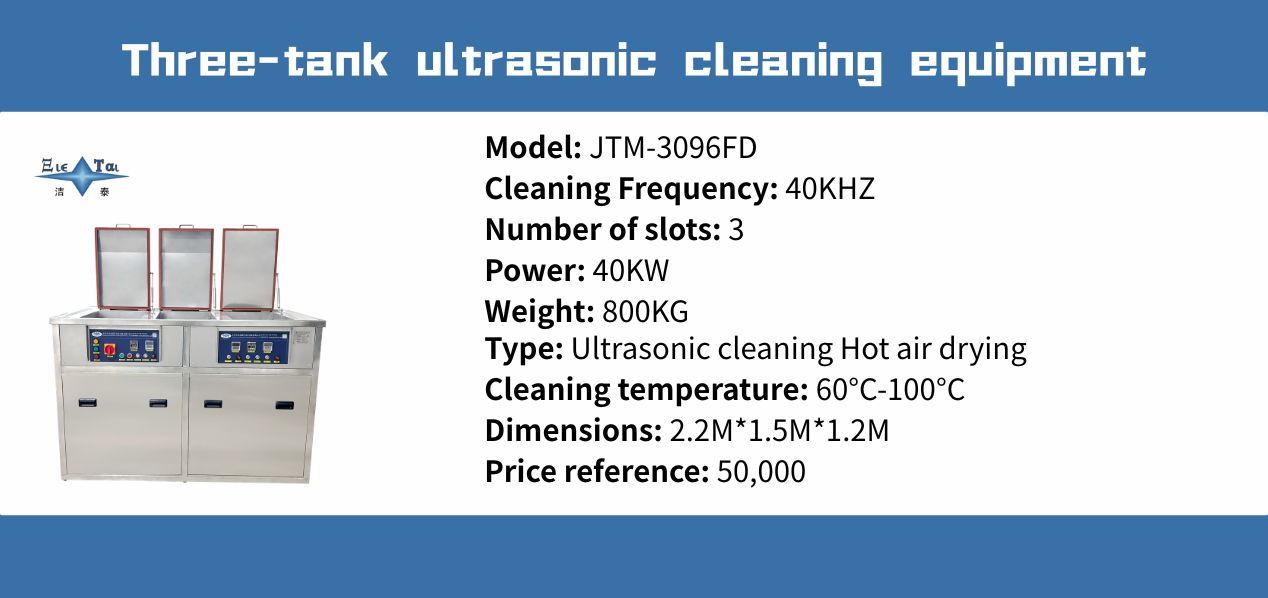

| Model Number: | JTM-3096FD |

| Certification: | CE, FCC, ROHS, etc. |

| Place of Origin: | Dongguan, Guangdong |

| MOQ: | 1 |

| Price: | ¥50000 |

| Payment Terms: | T/T |

| Supply Ability: | One unit requires 60 days. |

| Delivery Time: | 30-60work days |

| Packaging Details: | Packaging: Wooden case, wooden frame, stretch film. Dimensions:2.2M*1.5M*1.2M |

| Cleaning frequency: | 40KHZ |

| Cleaning temperature: | Normal temperature60℃-100℃ |

| Power: | 40KW |

| Weight: | 800KG |

| Model: | JTM-3096FD |

| Number of tanks: | 3 tanks |

| Type: | Ultrasonic cleaning and hot air drying |

| Dimensions: | 2.2M*1.5M*1.2M |

| Company Info. |

| guangdong Jietai Ultrasonic cleaning Equipment Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Three-groove ultrasonic cleaning and drying machine in the hardware

industry

—— Integrated solution for heavy oil cleaning and fast drying

Product positioning

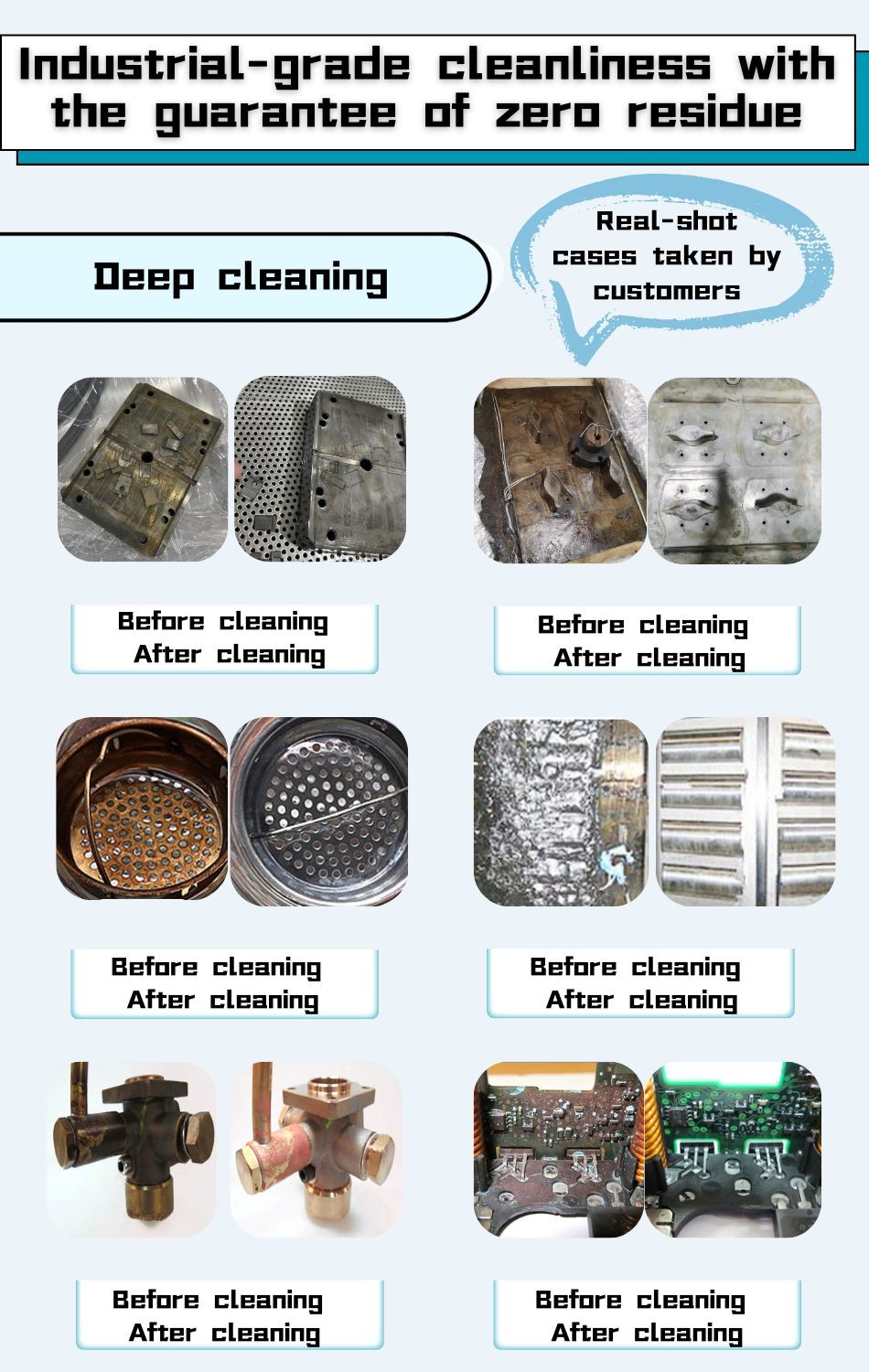

The three-tank ultrasonic cleaning equipment specially designed for

hardware processing parts (bearings/gears/fasteners/molds)

integrates three core modules: 40kHz medium frequency ultrasonic

cleaning, multi-stage rinsing, and hot air constant temperature

drying, and achieves 99.6% oil removal rate and 0.1mm blind hole

without residue for cutting fluid residues, grease, metal chips

(≥5μm) and other pollutants. The equipment adopts a three-tank

conjoined design (cleaning tank, rinsing tank, drying tank),

suitable for small and medium-sized batch production

(10-100kg/batch) and automatic production line, to meet the

high-precision cleaning needs of metal electroplating, spraying and

assembly, and the surface tension of the workpiece after drying is

≥ 72mN/m, which significantly improves the yield of subsequent

processes (such as the electroplating leakage rate is reduced by

50%).

1. Special support for the hardware industry

Free Sample Test:

▶ Customers provide workpieces and contaminant samples, and issue

oil film residue and particle size test reports within 48 hours

▶ For special-shaped parts (such as deep-hole valve body), free

design of polyoxymethylene (POM) positioning bracket (positioning

error<1mm)

Customized process development:

✔ Provide special solutions such as cleaning before electroplating

and spraying, and adapt to special materials such as zinc alloy and

magnesium alloy

✔ It supports docking with the PLC system of the production line to

realize the automatic linkage of the loading and unloading robot

2. Full-cycle O&M guarantee

Intelligent Fault Warning:

▶ Vibration sensor to monitor ultrasonic transducer anomalies (95%

accuracy) and pressure sensor to warn of spray blockage (response

time<15 seconds)

▶ Remote diagnosis system: real-time monitoring of equipment status

through the 4G module, and automatic push alarm to the mobile phone

when abnormal

Fast Spare Parts Response:

✔ Reserve ultrasonic transducers, heating tubes, filter elements

and other wearing parts, and deliver them within 72 hours

nationwide

✔ Provide annual in-depth maintenance (including tank passivation,

circuit inspection) to ensure stable equipment performance

|