| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Ultrasonic Cleaning Equipment |

|---|---|

| Brand Name: | Jietai |

| Model Number: | JT-TQ60198AD |

| Certification: | CE, FCC, ROHS, etc. |

| Place of Origin: | Dongguan, Guangdong |

| MOQ: | 1 |

| Price: | ¥1500000 |

| Payment Terms: | T/T |

| Supply Ability: | One unit requires 60 days. |

| Delivery Time: | 30-60work days |

| Packaging Details: | Packaging: Wooden case, wooden frame, stretch film. Dimensions: 8M*2.2M*2.8M |

| Name: | Hydrocarbon Cleaning Machine |

| Cleaning frequency: | 25KHZ |

| Cleaning temperature: | Normal temperature - 120℃ |

| Power: | 120KW |

| Weight: | 8 tons |

| Model: | JT-TQ60198AD |

| Number of tanks: | 6 tanks |

| Type: | Vacuum ultrasonic cleaning: Vacuum steam drying |

| Dimensions: | 8M*2.2M*2.8M |

| Company Info. |

| guangdong Jietai Ultrasonic cleaning Equipment Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

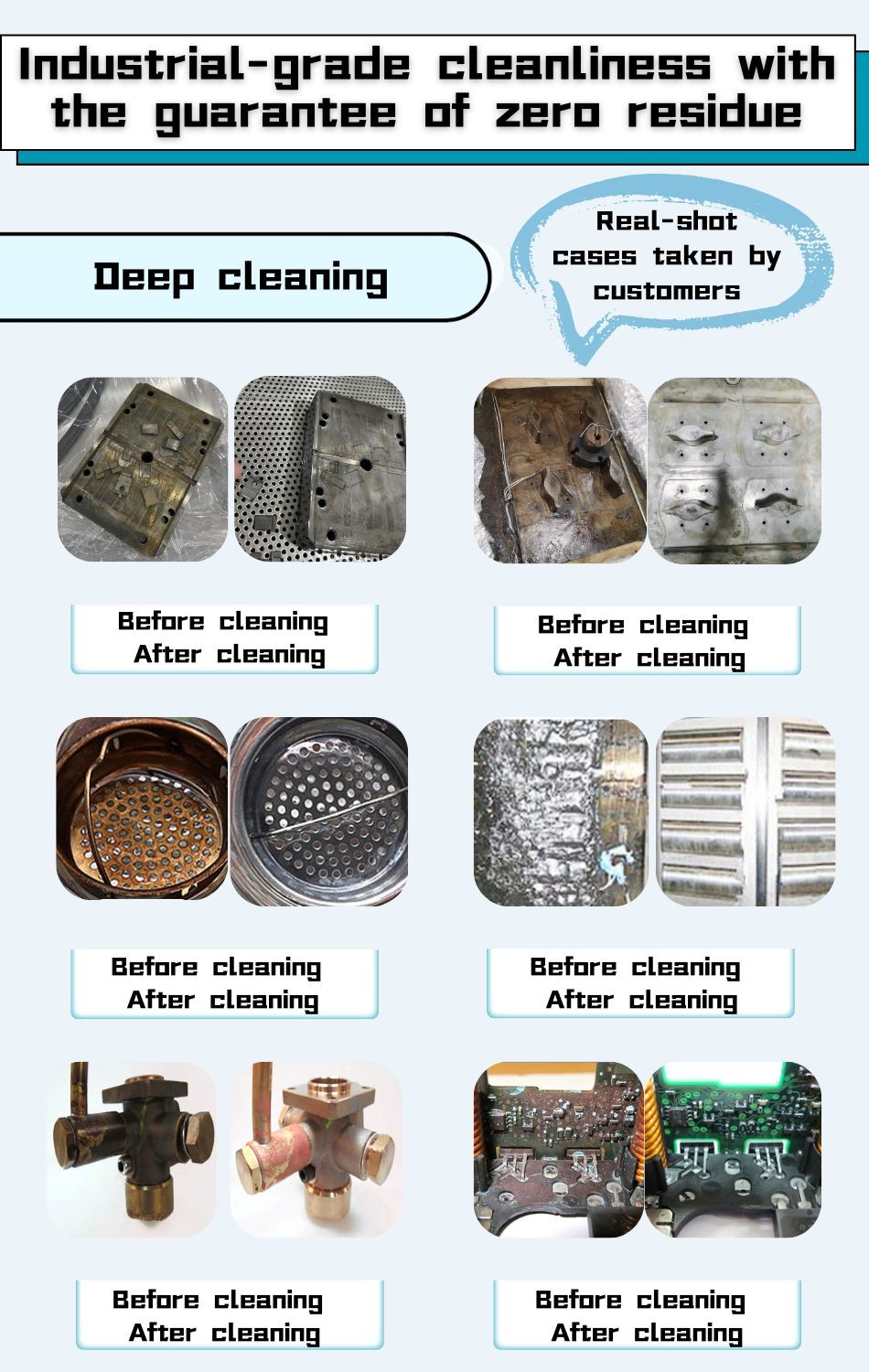

【Powder Metallurgy】Six-Tank Automatic Hydrocarbon Cleaning

Equipment, Vacuum Ultrasonic Cleaning, Vacuum Steam Drying

——Precision cleaning solution for the whole process of MIM

parts/structural parts/gears

Product positioning

The intelligent six-tank continuous cleaning equipment specially

designed for powder metallurgy parts (MIM metal injection molded

parts, powder metallurgy gears, bearing seats, structural parts)

integrates three core modules: vacuum ultrasonic degreasing, vacuum

vapor drying, and solvent recycling and regeneration, and achieves

a 99.8% organic matter removal rate and 0.1μm blind hole

cleanliness for molding lubricants (paraffin-based/PEG), metal

powder residues, sintering oil and other pollutants on the surface

of powder metallurgy parts. The equipment adopts fully automatic

PLC control (supports 200 sets of process formulas), which is

suitable for small and medium-sized batch and multi-variety

production (5-200kg/hour), which meets the high-precision cleaning

needs of powder metallurgy parts before degreasing, sintering and

electroplating, and the surface tension of the parts after drying

is ≥72mN/m, which effectively improves the compactness of

subsequent sintering and coating adhesion (the defective rate is

reduced by 40%).

Intelligent control system

1. Whole-process automation

PLC touch screen control:

▶ The 12-inch industrial-grade touch screen supports 3D process

simulation, and displays 30 parameters such as vacuum, temperature,

and solvent concentration of each tank in real time

▶ Automatic recognition of part type (barcode scan/weight sensor)

and matching to the optimal cleaning recipe (e.g. degreasing

program for MIM parts, cleaning program before gear sintering)

Safety Interlock Mechanism:

✔ Five-stage explosion-proof design: LEL concentration monitoring

(10% LEL), abnormal vacuum alarm (deviation >5%), solvent leak

detection (response time<10 seconds)

✔ When the equipment is running, a 300N mechanical locking force is

applied to the hatch to prevent misoperation and safety accidents

2. Data traceability and quality control

SPC reports with vacuum curves, solvent conductivity, weight

difference before and after drying, and MES system integration (ISO

9001:2015 compliant)

Equipped with a particle counter (0.1μm class) to automatically

record residual particle data on the surface of the part after

cleaning, it meets the requirements of IATF 16949 automotive

quality system

|