| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Calcite Mill |

|---|---|

| Brand Name: | Hengcheng |

| Model Number: | HVM series |

| Certification: | ISO Patent Certificate High-Tech Product Certificate |

| Place of Origin: | CHINA |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 5 sets/month |

| Delivery Time: | 120 days |

| Packaging Details: | Standard shipping packaging |

| Name: | calcite vertical roller mill |

| Model: | HVM800,HVM1100,HVM1300,HVM1500,HVM1700,HVM1900,HVM2200,HVM2800 |

| Capacity: | 1 - 50 t/h |

| Feed Particle Size: | 1-50mm |

| Finished Product Fineness: | 10-40um(97% pass rate) |

| Dust Removal Equipment: | Pulse Bag Filter / Cyclone Dust Collector |

| Applicable materials: | Limestone, calcite, gypsum, bentonite, spodumene |

| Motor Power: | Based on actual selection |

| Control System: | PLC Automatic Control |

| Lubrication System: | Force Lubrication |

| Company Info. |

| Hefei Hengcheng Industrial Equipment Technology Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Overview: Calcite Vertical Mill – An Efficient Grinding Solution

The application scenarios of vertical grinding of calcite are

concentrated in the deep processing of non-metallic minerals and

downstream terminal industries. The core is to grind calcite into

calcium carbonate powder of different fineness, which is suitable

for the raw material needs of multiple industries.

1. Paper industry

2. Coatings and paint industry

3. Plastic and rubber industry

4. Building materials and decoration industry

5. Chemical and food industries

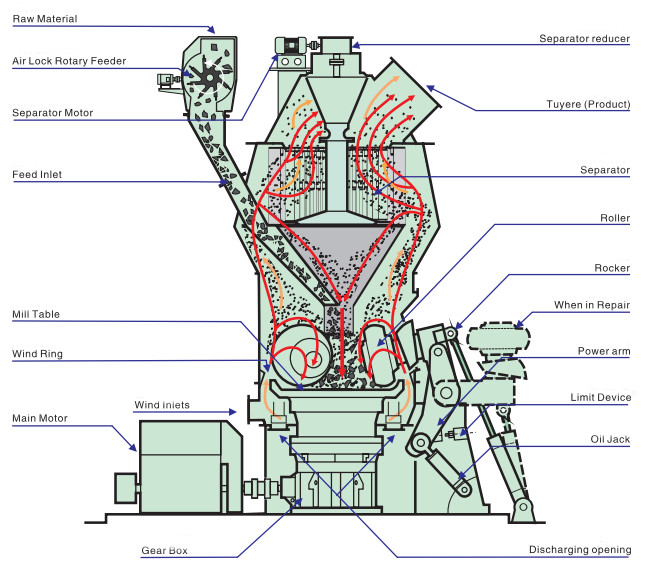

The calcite vertical mill is an advanced grinding equipment specifically designed for large-scale, high-efficiency production of calcite (calcium carbonate) powder. Utilizing a vertical structure, roller grinding principle, and an integrated classification system, it processes large chunks of calcite ore into various products ranging from coarse powder to ultra-fine powder (typically achieving 150–2500 mesh). This equipment is widely used in industrial fields such as plastics, paints, coatings, papermaking, and building materials.

| Specifications | HVM800 | HVM1250 | HVM1300 | HVM1500 | HVM1700 | HVM1750 | HVM1900 | HVM2400 | HVM2400 | HVM2500 |

| Grinding table median diameter | 800 | 1250 | 1300 | 1500 | 1700 | 1750 | 1900 | 2400 | 2400 | 2500 |

| Capacity(t/h) | 1-3 | 2-7 | 3-12 | 4-16 | 6-24 | 7-27 | 7-28 | 9-35 | 10-39 | 11-45 |

| Materials Grain Size(mm) | 0-15 | 0-20 | 0-25 | 0-35 | 0-35 | 0-35 | 0-40 | 0-40 | 0-40 | 0-50 |

| Materials Moisture(%) | <5 | |||||||||

| Product Fineness(10-40um) | 97% | |||||||||

| Product Moisture(%) | ≤1 | |||||||||

| Main Motor Power(kw) | 55 | 132 | 180 | 250 | 355 | 400 | 450 | 560 | 630 | 710 |

Re:The data based on Mohs'hardness 3-4 material

The product fineness can reach 10 um(1250 mesh)

Main Technical Advantages

Compared to traditional mills (such as ball mills and Raymond

mills), the calcite vertical mill offers significant advantages:

- **High Grinding Efficiency**: The material bed grinding principle ensures energy is directly applied to the material layer, reducing energy consumption by 20%-30% compared to ball mills.

- **Low Operating Costs**: Direct contact between the grinding rollers and the disc minimizes wear and metal consumption. The simple structure allows for easy maintenance.

- **Flexible Product Adjustment**: The fineness of the finished product can be easily and quickly adjusted by changing the classifier speed and grinding roller pressure without the need for shutdowns.

- **Strong Drying Capacity**: The integration of hot air enables simultaneous grinding and drying, handling materials with moisture content of up to 15%.

- **Small Footprint**: The compact vertical structure occupies about 50% less space than ball mill systems with equivalent output.

- **Low Noise and Environmental Friendliness**: The fully enclosed system minimizes dust emissions and operates with low noise levels.

|