| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Water Pump Seals |

|---|---|

| Brand Name: | JG |

| Model Number: | Replace John Crane 2100 |

| Certification: | FDA certificate |

| Place of Origin: | Zhejiang, China |

| MOQ: | 1pcs |

| Price: | USD8.75- 9.75 / 10 set |

| Payment Terms: | T/T,Western Union,MoneyGram |

| Supply Ability: | 1000PCS |

| Delivery Time: | 3~10DAYS |

| Packaging Details: | white box |

| Product name: | Rubber Bellows Seal 2100 |

| Feature: | Rubber Bellows |

| Application: | Water pumps |

| Shaft diameter: | 16~120mm |

| Temperature: | -20~150°C |

| Pressure: | up to 1.2Mpa |

| Company Info. |

| Jiaxing Burgmann Mechanical Seal Co., Ltd. Jiashan King Kong Branch |

| Verified Supplier |

| View Contact Details |

| Product List |

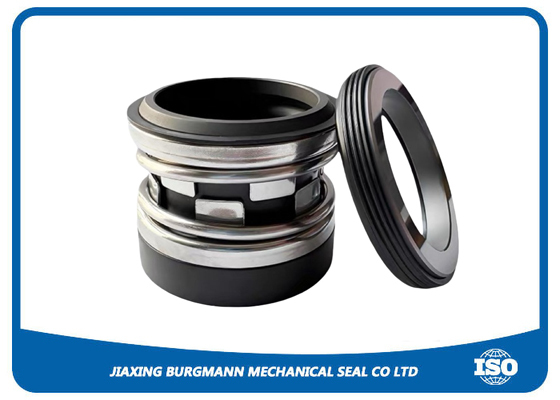

Rubber Bellows Mechanical Seal Replace John Crane 2100

The Model 2100 is a rubber bellows mechanical seal designed for water pump applications. Its elastomer bellows construction provides effective compensation for shaft runout and minor misalignments. This seal configuration typically incorporates a carbon ceramic face combination, ensuring reliable performance in residential and commercial water circulation systems. The unit's compact design facilitates straightforward installation in standard pump housings, delivering durable sealing for clean water service with minimal maintenance requirements.

Operating Limited:

| Shaft diameter | 16~120mm |

| Pressure | up to 1.2Mpa |

| Temperature | -20~150°C |

| Slidingvelocity | 10m/s |

Material:

| Rotary Ring | Car / SIC/TC/Cer |

| O-Ring | , EPDM, NBR, AFLAS, Kalrez,PTFE |

| Spring and Metal Parts | SUS304, SUS316 |

| Stationary Ring | Car / SIC /TC/Cer |

Advantages:

Application:

Shipping & Payment Terms:

Port of Loading: Shanghai

Shipping Method: DHL,UPS,FEDEX,TNT, etc

Payment Terms: T/T, Western Union, money gram

Our services:

Q&A:

Q1: What is the primary functional advantage of the rubber bellows

in the Model 2100?

A1: The elastomeric bellows serves as a dynamic sealing element

that compensates for axial shaft movement, minor shaft

misalignment, and face wear. Its flexibility provides superior

vibration damping compared to rigid pusher-type seals, making it

ideal for applications in smaller, high-RPM motors.

Q2: For which specific pump types is the Model 2100 typically

specified?

A2: This seal is predominantly engineered for use in light-duty

centrifugal pumps. Common applications include domestic water

circulation pumps, automotive coolant pumps, and various OEM

equipment pumps handling non-aggressive, clear liquids.

Q3: What are the standard face material pairs available for the

Model 2100, and how are they selected?

A3: The standard configuration typically features a carbon primary

face running against a ceramic stationary face. This combination

provides excellent dry-running tolerance and reliable performance

for water-based fluids. For extended service life in slightly

abrasive or higher-temperature water, an upgrade to a silicon

carbide stationary face is often recommended.

Q4: How does the Model 2100's performance compare to a pusher-type

seal in a water pump application?

A4: In clean water service, the Model 2100's bellows design offers

a distinct advantage by eliminating the hang-up risk associated

with pusher seal auxiliary components (like O-rings or PTFE wedges)

that can stick in their bore. This results in more consistent face

loading and reliable sealing in applications where mineral deposit

formation is a concern.

Q5: What is the most critical factor during the installation of

this seal to prevent premature failure?

A5: The most critical step is ensuring the sealing faces remain

completely free of contamination. Even microscopic particles

introduced during handling can score the finely polished faces.

Additionally, the bellows must be seated squarely on the shaft

without any twisting or rolling, which can create a leak path and

impede its ability to flex.

Q6: What chemical compatibility issues should be considered with

the rubber bellows?

A6: The standard bellows elastomer is typically Nitrile (NBR),

which is suitable for water and glycol-based coolants within its

temperature range. However, exposure to chlorinated water, ozone,

or certain aliphatic solvents can cause the elastomer to harden and

crack, leading to catastrophic failure. For such media, specifying

a bellows made of EPDM or FKM (Viton) is essential.

Q7: Can the Model 2100 be used in a dual-purpose coolant/air

conditioning pump?

A7: While it may function, this is not generally recommended

without verification. Refrigerant compatibility with the standard

NBR bellows is poor, and the lubricity of the fluid differs

significantly from water. A seal specifically engineered for A/C

compressor duty, often with an HNBR or FKM bellows, should be used

for that application.

Q8: What are the tell-tale signs of a failing Model 2100 seal

during operation?

A8: Initial failure often presents as a fine, barely visible mist

or persistent dampness around the seal gland. As degradation

progresses, this advances to a steady drip. In advanced stages,

coolant contamination or audible squealing from the faces may

occur, indicating significant face damage or bellows hardening.

|