| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Linear Servo Motor |

|---|---|

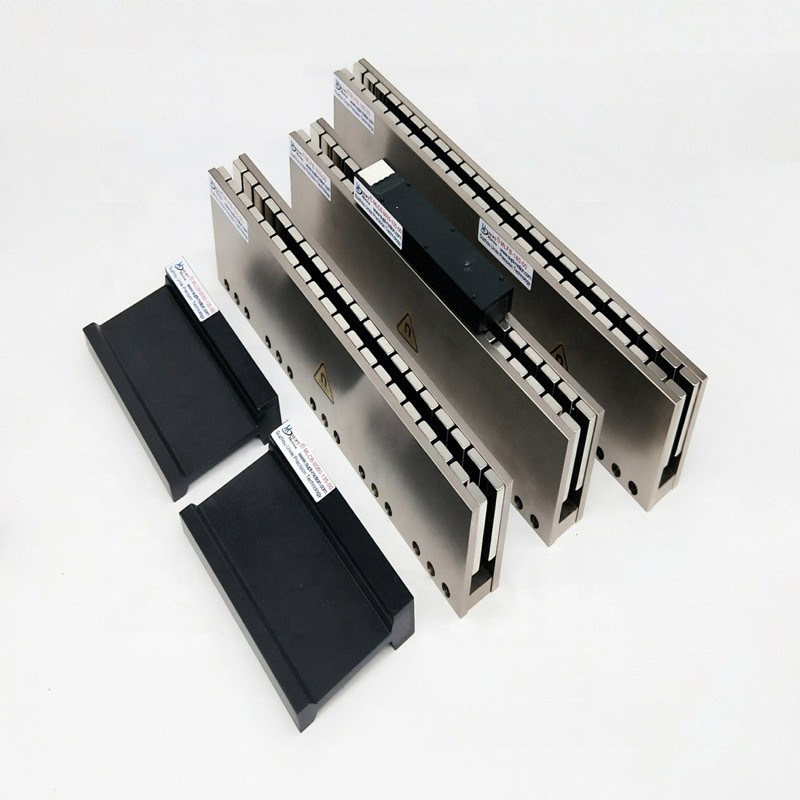

| Brand Name: | SUPT |

| Model Number: | A Series |

| Certification: | 3C, CE, ISO9001 |

| Place of Origin: | Jiangsu, China |

| MOQ: | ≥1 |

| Price: | $150.00/pieces >=1 pieces |

| Payment Terms: | T/T |

| Supply Ability: | To be negotiated |

| Delivery Time: | 1-5pcs ,5 days . >20pcs ,To be negotiated |

| Packaging Details: | in carton and as customer requirements small linear motor |

| Warranty: | 3months-1year |

| Usage: | BOAT, Car, Electric Bicycle, UAV, robot, Medical ventilator, microscope, endoscope, optics, optical lens |

| Type: | Micro Motor |

| Torque: | Requests |

| Construction: | Permanent Magnet |

| Protect Feature: | Totally Enclosed |

| Speed(RPM): | High Speed |

| Continuous Current(A): | Current |

| Efficiency: | IE 1 |

| Product Name: | Linear Actuator |

| Application: | Automatic Product |

| Motor type: | Permanent Motor |

| Keywords: | Small Linear Motor |

| Name: | A Series Motor |

| Rated Voltage: | 1.2-12V |

| Size: | 30mm |

| Color: | Silver |

| Item: | Mini Electric Motors |

| Packing: | in carton |

| Port: | Shanghai Port |

| Company Info. |

| Suzhou Unite Precision Technology Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

The linear motor's armature consists solely of coils without

magnets, eliminating magnetic attraction between moving and

stationary parts. This design prevents cogging effects, ensuring

smooth operation. Its lightweight construction enables high-speed

and high-acceleration performance. The thrust characteristics are

smooth, achieving high precision when paired with linear encoders.

The stroke can be extended arbitrarily, operating silently and

maintenance-free. Features imported epoxy resin vacuum-filled at

high temperature and pressure, along with highly flexible power

cables. Widely applied in semiconductor manufacturing equipment,

precision testing equipment for the flat-panel display industry,

laser cutting/marking machines, and machine vision inspection

systems. Modular design allows for custom machining.

Linear motor technology is the core driver advancing semiconductor

manufacturing equipment, serving as the essential direct drive for

achieving precise wafer positioning and high-speed motion.

Leveraging its high precision, speed, acceleration, and smooth

motion characteristics, the linear motor enables precise wafer

extraction from cassettes within wafer transfer systems,

high-accuracy placement onto processing stations, and rapid return

of wafers to cassettes post-processing.

Within precision positioning platforms, linear motors support and

precisely position wafers. Wafer carriers must perform

nanometer-level stepping and scanning movements within the XY plane

to complete exposure. In microscopes and defect detection

equipment, wafers must also be accurately moved beneath inspection

probes.

| Linear motor performance parameters | |||||||

| A Series--MLCA(Dynamic) MLFA(Stator) | |||||||

| Model/Par | MLCA-0020-075-00 | MLCA-0040-135-00 | MLCA-0080-255-00 | ||||

| Peak force(Fp) | N | 60 | 120 | 240 | |||

| Peak current(lp) | Amps | 4.8 | 4.2 | 4.2 | |||

| Continuous force(Fc) | N | 20 | 40 | 80 | |||

| Continuous current(lc) | Amps | 1.6 | 1.4 | 1.4 | |||

| Actuator constants(DC motor conversion/3p)(Ka) | N/W | 5.65 | 7.9 | 11.2 | |||

| Constant Thrust(L-L)(Kf) | N/Amps | 15.3 | 30.4 | 60.3 | |||

| Back EMF constant(L-L)(Kb) | V/m/sec | 8.8 | 17.6 | 34.8 | |||

| Electrical constant(Te) | ms | 0.3 | 0.3 | 0.3 | |||

| Resistance(L-L)(R) | @25℃Ω | 4.8 | 9.4 | 19.2 | |||

| Inductance(L-L)(l) | mh | 1.51 | 3 | 6 | |||

| Heat transfer coefficient(Rth) | ℃/W | *3.9 | *1.9 | **1.3 | |||

| Coil maximum temperature(Tmax) | ℃ | 120 | 120 | 120 | |||

| Magnet Pole pitch(2T) | mm | 30 | 30 | 30 | |||

| Mover weight | Kg | 0.24 | 0.42 | 0.82 | |||

Linear Motors Compared to Traditional Rotating Motors:

| Characteristics | Linear Motor | Traditional Transmission Methods (Screw/Belt) | ||||

| High Precision | Direct drive with no intermediate transmission components eliminates backlash and backlash error, enabling nanometer level positioning accuracy. | Backlash, elastic deformation, and friction exist, limiting precision typically to the micrometer level. | ||||

| High Speed and Acceleration | Reaches speeds of several meters per second and accelerations exceeding 10G, significantly boosting equipment throughput. | Limited by screw rotational,speed and inertia, resulting in lower speed and acceleration. | ||||

| High Smoothness | Smooth motion with non-contact transmission and minimal vibration. Critical for vibration-sensitive processes like lithography. | Contact friction within the transmission chain can generate vibration and noise. | ||||

| High Cleanliness | Lubrication-free operation eliminates grease or wear particles, meeting the ultra- high cleanliness requirements of semiconductor manufacturing. | Lubrication is required, posing a contamination risk. | ||||

| High Reliability and Long Service Life | Primary and moving parts (magnetic track and coil) have no mechanical contact, resulting in minimal wear and extended lifespan. | Multiple mechanical contact points are subject to wear, requiring regular maintenance. | ||||

| Vacuum Compatibility | Easily designed for vacuum- compatible models, making it ideal for vacuum process equipment. | Lubrication and heat dissipation pose significant challenges in vacuum environments. | ||||

|