| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | VSA Oxygen Generator |

|---|---|

| Brand Name: | Since |

| Model Number: | VPSA-1200-12B |

| Certification: | CE |

| Place of Origin: | Suzhou, China |

| MOQ: | 1set |

| Price: | according to customer needed equipment |

| Payment Terms: | L/C,T/T |

| Supply Ability: | 300set per year |

| Delivery Time: | 5month |

| Packaging Details: | wooden case |

| Process form: | Vacuum pressure swing adsorption (VPSA) |

| Purity: | 90 - 95% |

| Flow: | 100m3 - 5000m3 / h |

| Outlet pressure: | 20Kpa - 0.5Mpa |

| Unit consumption of oxygen production: | 0.36kmh - 0.40kmh/NM3 |

| Area covered: | 500M2 |

| Life: | 15years+ |

| Company Info. |

| JoShining Energy & Technology Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

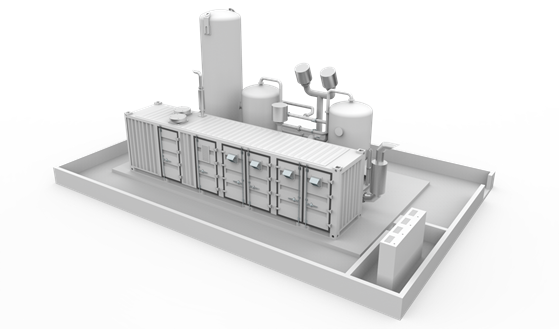

Fully automatic operated VSA Oxygen Generator / Plant For Gold Mine

Why Gold Mine need to use VSA Oxygen Generator?

The core purpose of using VPSA/VSA oxygen generators in gold mines

is to provide a large amount of stable and inexpensive oxygen rich

gas (usually 90-95% oxygen) for the "roasting cyanide" or "direct

cyanide" gold extraction processes, to replace or supplement

expensive pure liquid oxygen, essentially a process revolution and

cost revolution. It is no longer simply "buying oxygen", but

transforming oxygen from an "expensive purchased raw material" into

a "self-produced, inexpensive process gas" through self built

oxygen factories.

Main value and function of VSA Oxy Generator for Gold Mine:

*Economy: Significantly reduce the cost of oxygen, thereby lowering

the production cost per ounce of gold.

*Efficiency: Improving leaching rate and equipment processing

capacity is equivalent to expanding production capacity.

*Environmental friendliness: Reducing the amount of cyanide used

reduces the pressure of environmental treatment.

*Stability: Oxygen is produced and used independently, with stable

and reliable supply, and is not affected by external markets

| Oxygen parameters | Flow Nm³/h | 1200~1300 | 93% Total oxygen flow at purity |

| Pressure PSI | 11~13 | With full oxygen combustion system | |

| Purity % | 93% | ||

| Altitude | 1280 | ||

| Public and auxiliary engineering needs | Run the power consumption KW | 576 +/-5% | Design conditions under full load flow |

| Cooling water recycle system T/h | N/A | ||

| Instrument air Nm³/h | ~ 120 | ||

| Seal water softening m³/h | N/A | Dry vacuum fan unique technology | |

| Area m2 | 350 ~ 500 | It can be adjusted according to the actual situation | |

| Other Performance parameters | L/T months | 5 | |

| Load regulation % | 50~100 | Variable power saving | |

| Noise dBA | <=85 | Based on typical plant design conditions | |

| Annual opening rate % | >=98 % | Annual maintenance stops less than 7 days | |

| Gas supply reliability % | 100% | Add the liquid oxygen backup system | |

| Liquid oxygen standby(option) | Liquid oxygen backup system m³ | 50 | On-site liquid oxygen system (sufficient for over 40 hours of usage) |

Process:

Air inlet filter - Air blower (in container) - Adsorber A - Adsorber B - Gox buffer - Compressor (in container) - Oxygen storage tank - outlet

l l Vacumm pumb(in container)

Applications:

We supplied to many customers in country of Philippines, Russia, Myanmar, Indonesia, Ghana,Algeria, etc.

|