Polyurethane flip-flop screen panels excel at screening challenging

materials—wet, sticky, or dry—thanks to their unique motion. The

flip-flop action keeps surfaces clear of debris, preventing

blinding and maintaining high efficiency. Made from durable

polyurethane, they resist abrasion from ores and sand, lasting

longer than traditional wire screens.

Ideal for vibratory screens in mining and construction, they can be

customized by hardness, thickness, or aperture size. Installation

is simple with bolt-free clamping, and their self-cleaning design

reduces maintenance. They also cut noise compared to metal screens,

making workplaces safer. For consistent performance, they’re a top

choice.

Key Features & Benefits for Flip-Flop Screen Panel 8mm Holes 7mm

Thickness used for Wet Clay Screening

Specifications of Flip-Flop Screen Panel 8mm Holes 7mm Thickness

used for Wet Clay Screening

Product Close-up Views for Flip-Flop Screen Panel 8mm Holes 7mm

Thickness used for Wet Clay Screening

Working Process for Flip-Flop Screen Panel 8mm Holes 7mm Thickness

used for Wet Clay Screening

Packaging & Logistics for Flip-Flop Screen Panel 8mm Holes 7mm

Thickness used for Wet Clay Screening

Wooden box package for secure transportation.

Applications for Flip-Flop Screen Panel 8mm Holes 7mm Thickness

used for Wet Clay Screening

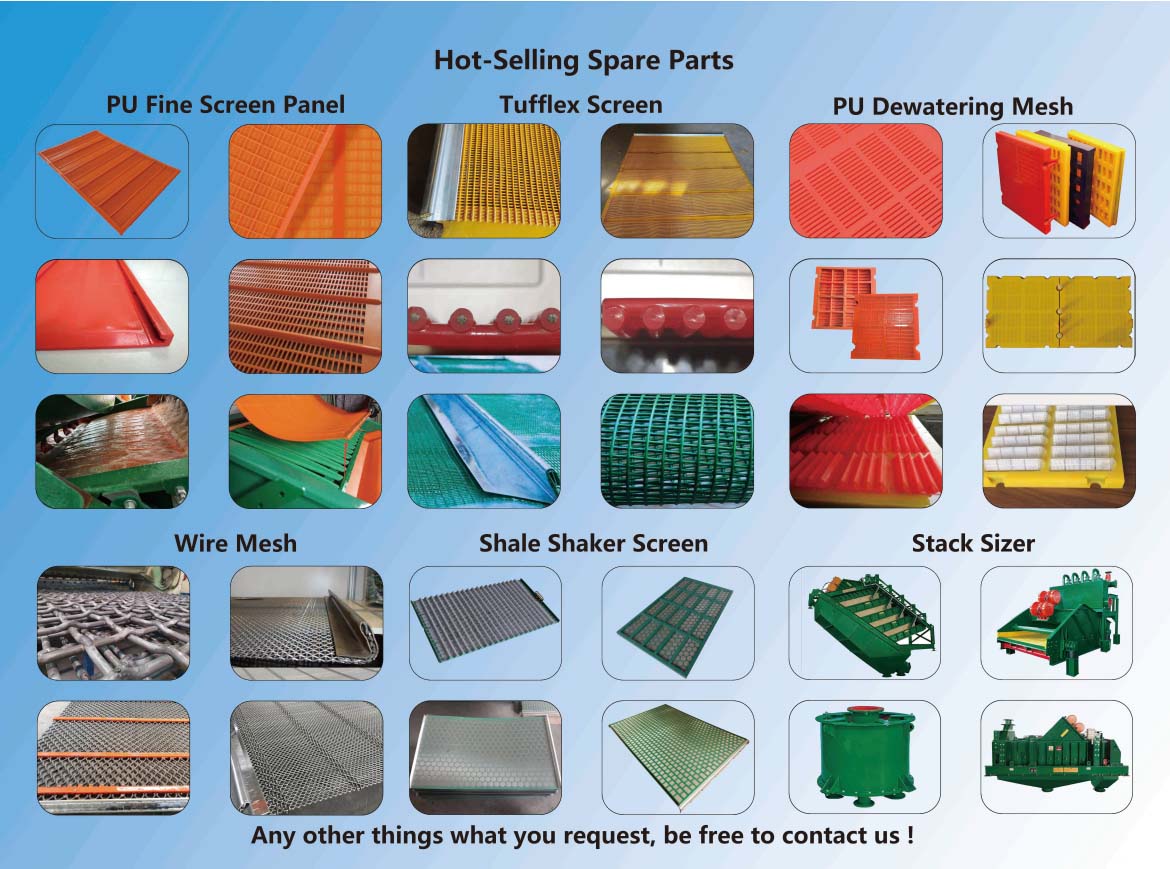

Polyweb Urethane Screen

Tufflex Screen

Polyurethane Dewatering Screen Mesh

WS 85 Modular Screen

Polyurethane Screen Panels

Rotex Replacement Screens

Rubber Screen Panel

Vibrating Screen Mesh

Self cleaning Wire Mesh

Shale Shaker Screen