| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Other Storage Racking |

|---|---|

| Brand Name: | Hua Yide |

| Model Number: | Radio shuttle racking |

| Certification: | CE ISO14001 ISO9001 |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | can be negotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 900000KGS Per Month |

| Delivery Time: | 15 to 20 working days . |

| Packaging Details: | Plastic banding+Stretch film wrapped,easy loading and unloading with standard forklift truck or pallet jack . |

| Name: | Radio Shuttle Racking |

| Weight Capacity: | maximum 1500kg/pallet, Customized |

| Feature: | Corrosion Protection, Secure, Save space,Corrosion protection |

| Depth: | 1.5~3.0mm,Customized |

| Width: | 1350-1400mm |

| Finish: | Epoxy resin electrostatic spraying(powder coating) |

| Keyword: | shuttle racking system |

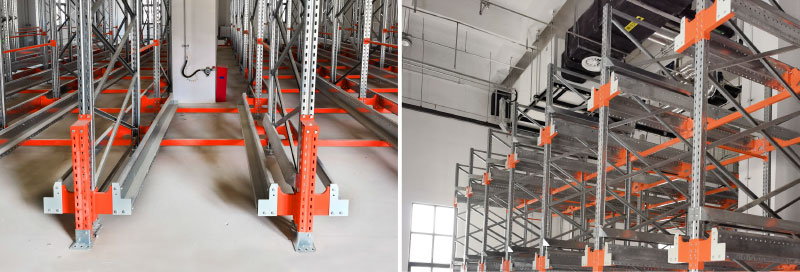

| Main parts: | column, beam, base plate, diagonal/horizontal bracing, bolt |

| MOQ: | 1 set |

| Company Info. |

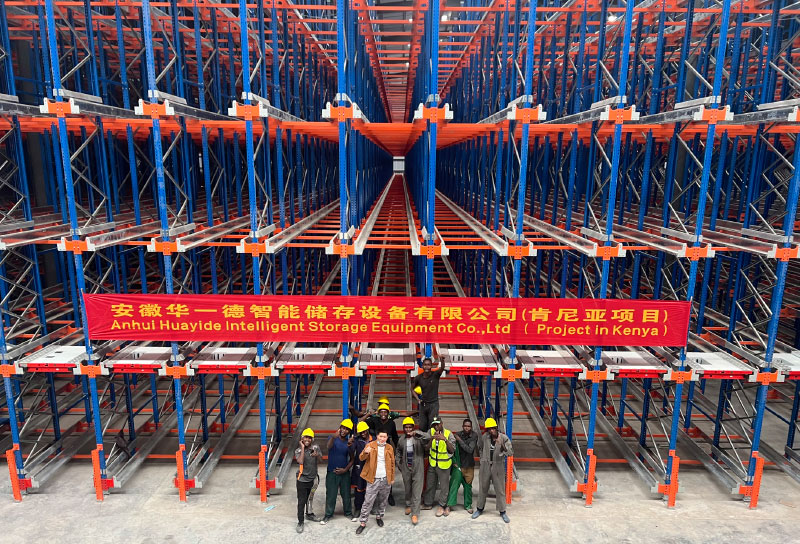

| Anhui Huayide Intelligent Storage Equipment Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

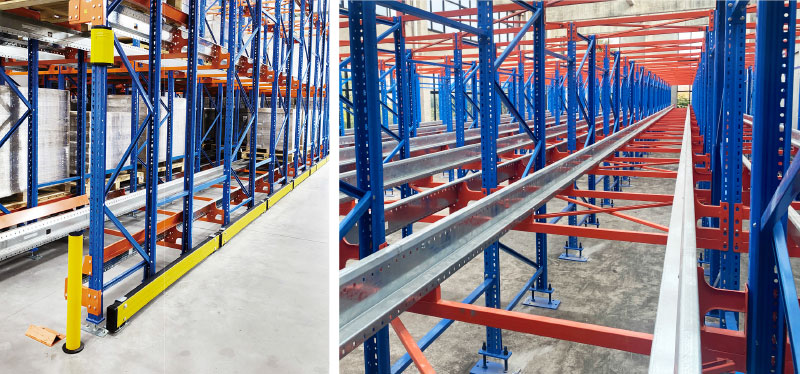

Radio Shuttle Racking

—— Common Design ——

Strong bearing capacity, easy installation, expansion space & durability.

Operating temperature: 0°C to +45°C

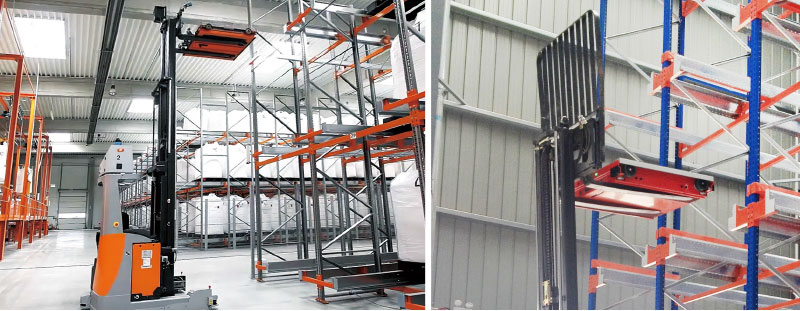

The Radio Shuttle Pallet Racking System is a high-quality, semi-automated storage solution for high-volume palletized loads and products. It's frequently used in warehouses, and distribution hubs for food and beverage products, or storage facilities with special storage conditions. The Radio Shuttle System is particularly effective when your logistics center needs to rapidly and efficiently supply a wide range of different businesses;

This Radio Pallet Shuttle Rack is the most common in various storage racking systems in China. First, the characteristics of the good's packaging and its weight must be counted to determine the type, specification and size of the pallet, and then the span, depth, layer spacing, height of the unit shelf should be determined. When loading and unloading goods, forklifts are mostly used, and electric stackers can also be used when the shelves are short. This kind of racking system has high space utilization, flexible and convenient access, supplemented by computer management or control, and can basically meet the requirements of modern logistics systems.

Customization

—

Please let us know the following information for a quick quote: 1.

The size of your warehouse; 2. Shelf width and depth; 3. Shelf

system height; 4. How many layers do you want; 5. The bearing

capacity of each layer; 6. All the colors you want.

We are one of the professional factories in china that are good at

the planning, design, manufacture and installation of shuttle

racking system. If you have any inquiry of radio pallet shuttle

rack, welcome to contact us. And the customized orders are also

welcome.

Radio Shuttle Racking · Warehouse Storage Rack · Made In China

Structural Principles

——

1) FIFO or FILO, Optional;

2) Goods can be stored in the warehouses with highest density and

low cost;

3) Accessibility is increased because all the levels can be

accessed at any time;

4) Minimizes damage to the rack because the forklift does not have

to travel into the racking;

Radio Shuttle Racking · Warehouse Storage Rack · Made In China

Key Features and Benefits

——

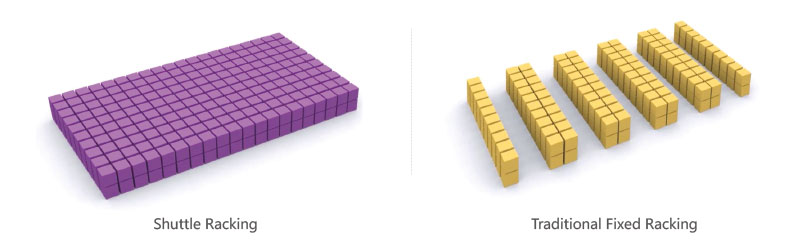

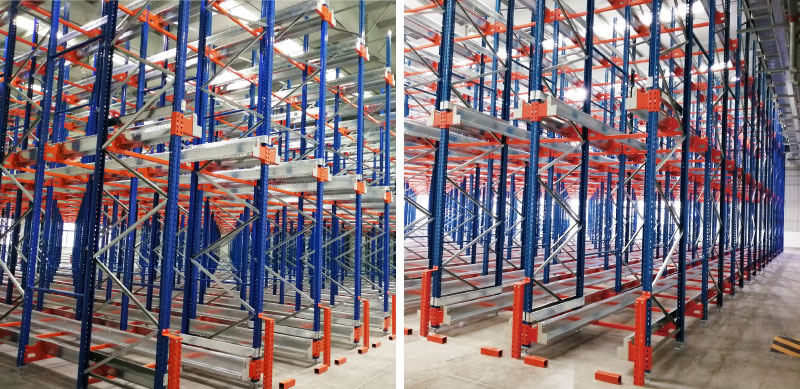

Maximized Storage Density: The radio shuttle system increases storage density by utilizing

deep lanes, allowing you to store multiple pallets in a compact

area. This maximizes the use of vertical and horizontal space,

making it ideal for warehouses with limited floor space.

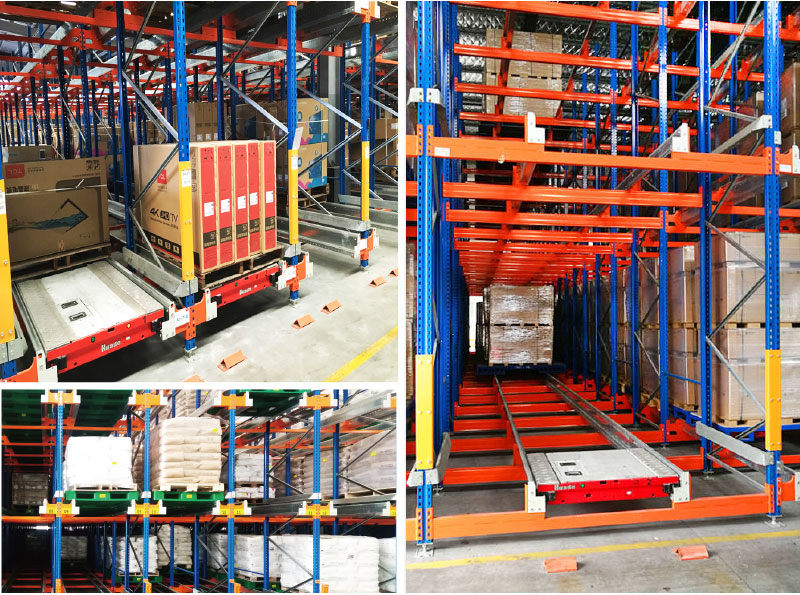

Faster and More Efficient Operations: With the motorized shuttle handling the movement of pallets, the

system reduces manual labor and increases picking speed. Forklift

operators only need to load and unload the shuttle, speeding up the

overall process.

Increased Throughput: The radio shuttle operates faster than manual systems, improving

overall throughput. It can quickly move pallets from deep within

the racking lanes to the front for easy retrieval.

Reduced Labor Costs: By automating the process of pallet movement within the system,

radio shuttle pallet racking reduces the need for manual labor,

lowering operational costs and increasing warehouse efficiency.

Improved Safety: With less forklift traffic and manual pallet

handling, the radio shuttle system reduces the risk of accidents

and injuries in the warehouse.

Optimized Space Utilization: The system's ability to store pallets in deep lanes with minimal

aisle space makes it perfect for businesses with limited space but

high storage demands.

Radio Shuttle Racking · Warehouse Storage Rack · Made In China

Product Parameters

—

| Material | High-strength steel or powder-coated steel |

| Load Capacity | Typically 1,000 kg to 1,500 kg per pallet, depending on design |

| Rack Height | Customizable to suit warehouse height, typically up to 12 meters |

| Rack Depth | Can accommodate up to 6 pallets deep, customizable |

| Shuttle Speed | Varies by system configuration, typically 1.5 meters per second |

| Lane Width | Typically 1,000mm to 1,200mm, adjustable based on pallet size |

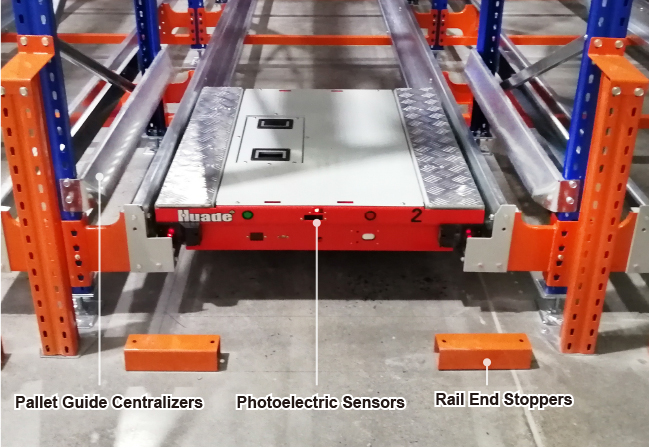

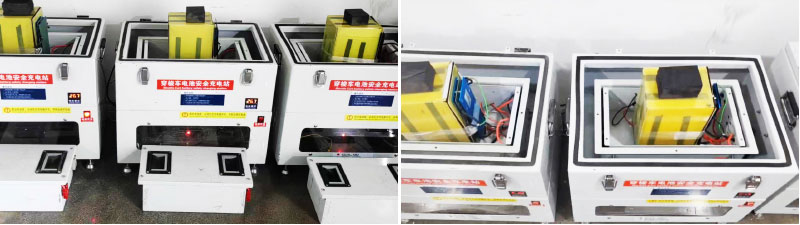

| Shuttle Type | Battery-operated, motorized shuttle with wireless radio control |

| Aisle Width | Narrow aisles (typically 1.5m to 3m) for maximizing storage space |

| Forklift Type | Standard reach trucks, counterbalance forklifts, or narrow-aisle trucks |

| Control System | Wireless radio communication for shuttle movement and pallet positioning |

| Inventory Management | Compatible with both LIFO and FIFO inventory management methods |

| Safety Features | Anti-collision sensors, safety barriers, and emergency stop features |

| Temperature Range | Suitable for both ambient and cold storage applications (-20°C to 0°C) |

| Finish | Powder-coated or galvanized steel for long-lasting durability |

| Battery | Rechargeable battery for shuttle, with long operational life and quick charging |

Radio Shuttle Racking · Warehouse Storage Rack · Made In China

Widely Used

Radio Shuttle Racking

Explosion-Proof Storage

—

Explosion-Proof Shuttle Rack + Explosion-Proof Shuttle Car

Cold Chain Racks

—

Radio Shuttle Rackings Made Of High Strength Steel Plate

Radio shuttle rack & four-way shuttle

—

Radio shuttle racking + four-wheel shuttle / eight-wheel shuttle

—

Radio Shuttle Rack+ Shuttle Carrier System

—

Radio Shuttle Rack + Stacker Crane

—

Radio Shuttle Rack +AGV

—

Radio Shuttle Racking · Warehouse Storage Rack · Made In China

Rack protectors

Radio Shuttle Racking · Warehouse Storage Rack · Made In China

Packaging & Shipping

—

Cargo Fixation: Ropes, straps, frames and other devices secure mezzanine rack components in transport to avoid movement/collision from vibration, sudden stops or turns. Heavier parts (uprights, beams) use multi-layer reinforcement for stability.

Vibration Damping: Rubber pads, foam boards and other shock absorbers are placed at the base and around goods to absorb transit vibration, protecting the rack's surface and structure—critical for preventing coating damage on treated racks.

Rain & Moisture Protection: Transport vehicles use high-quality waterproof tarpaulins to cover goods from rain. Desiccants are added in packaging during transit through humid areas or long trips to keep metal components dry and rust-free.

Radio Shuttle Racking · Warehouse Storage Rack · Made In China

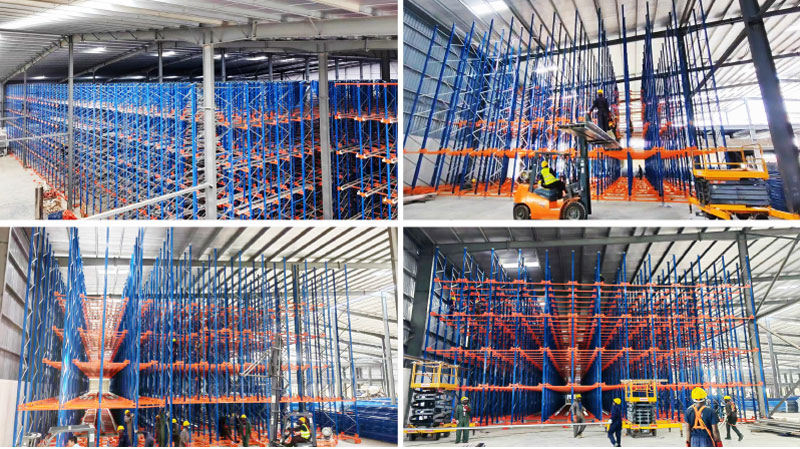

CASE

—

Radio Shuttle Racking · Warehouse Storage Rack · Made In China

Radio Shuttle Racking · Warehouse Storage Rack · Made In China

Radio Shuttle Racking · Warehouse Storage Rack · Made In China

Radio Shuttle Racking · Warehouse Storage Rack · Made In China

Radio Shuttle Racking · Warehouse Storage Rack · Made In China

Radio Shuttle Racking · Warehouse Storage Rack · Made In China

Ensure the quality of Huayide racking products

—

| 1 | The raw material of the shelf is customized from China's large steel group of high quality carbon steel, durable and strong, to ensure the quality of the product from the source. |

| 2 | The shelf welding adopts dioxygen protection welding, the welding joint has good cracking resistance, small welding deformation, beautiful forming, and does not need slag cleaning. |

| 3 | Each column and beam of the shelf are designed by professional personnel with professional technology and cut by professional equipment, so as to ensure the accurate size of the shelf. |

| 4 | Professional spray before treatment, oil removal, rust removal, phosphating, powder, and then in high temperature oven baking molding, wear-resistant, rust proof. |

Radio Shuttle Racking · Warehouse Storage Rack · Made In China

|