| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | GE Turbine Control |

|---|---|

| Brand Name: | GE |

| Model Number: | DS200TBCAG1AAB |

| Place of Origin: | US |

| MOQ: | 1pc |

| Price: | $1500 |

| Payment Terms: | T/T |

| Supply Ability: | 999pcs |

| Delivery Time: | 5-7days |

| Packaging Details: | New and original factory, individual box packing |

| Name: | GE DS200TBCAG1AAB Analog I/O Terminal Board Mark V Ge Turbine Control |

| Product ID: | DS200TBCAG1AAB |

| Series: | Mark V |

| Function: | Discrete Output pack |

| Product Net Depth/Length: | 330mm |

| Product Net Height: | 200mm |

| Product Net Width: | 100mm |

| Product Net Weight: | 2kg |

| Warranty: | 1year |

| Company Info. |

| Sumset International Trading Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

GE DS200TBCAG1AAB Analog I/O Terminal Board Mark V Ge Turbine Control

Product Details:

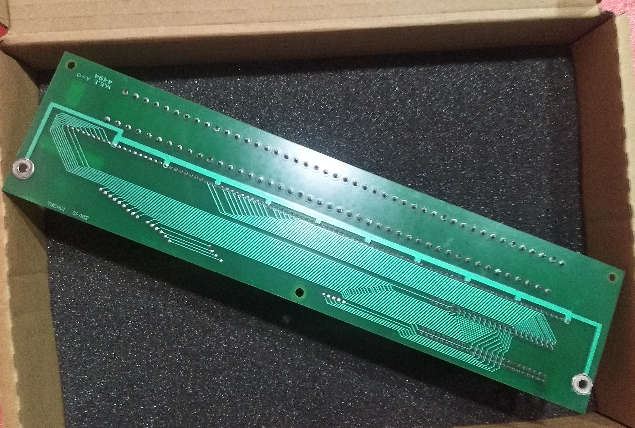

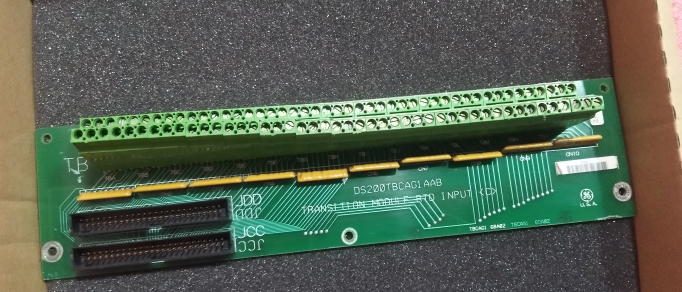

The GE DS200TBCAG1AAB is an Analog I/O Terminal Board designed for GE’s Mark V Turbine Control System—a robust, widely used system now replaced by newer Mark VI/Mark Vie models, but available in two variants: triple-redundant “TMR” (with two extra controllers) and single-channel Simplex. A revised version of the original DS200TBCAG1 parent board, it serves as a critical I/O interface, featuring two blocks of 90 signal wire terminals and two 50-pin connectors for linking to other Mark V components—including JCC/JDD connectors JCC for 1-15, JDD for 16-30 R5 Core signals.

It integrates with the Mark V’s I/O architecture: each I/O pack includes a local processor board and a specialized data acquisition board. Each I/O processor has a temperature sensor; excessive temperatures trigger diagnostic alarms, with real-time temperature and alarm logic stored in the database to support control actions or alerts.

Key Features:

Dual-Variant Mark V Compatibility: Meticulously tailored for both the triple-redundant TMR and

single-channel Simplex Mark V variants, adapting to the reliability

needs of critical and non-critical turbine setups alike—eliminating

the need for variant-specific terminal boards and simplifying

inventory management for operators with mixed Mark V fleets.

High-Density, Specialized I/O Connectivity: Boasts two 90-terminal blocks and two 50-pin connectors for

comprehensive signal routing, plus dedicated JCC/JDD connectors for

TCCA Board RTD signals—ensuring uninterrupted, low-interference

transmission of temperature data and supporting all analog I/O

needs of large-scale turbine systems in a single board.

No Configurable Hardware for Error-Free Operation: Lacks jumpers, DIP switches, or other movable components, removing

the risk of misconfiguration and wear from adjustments—delivering

“plug-and-play” compatibility with Mark V I/O architectures,

reducing troubleshooting time, and ensuring consistent performance

across deployments.

Integrated I/O Diagnostics with Proactive Alerting: Links to Mark V I/O packs equipped with high-precision temperature

sensors and real-time alarm logic—triggering diagnostics for

excessive heat, storing data in the system database, and enabling

proactive maintenance or control adjustments to prevent unplanned

downtime.

Legacy Reliability for Long-Term Continuity: As part of the widely deployed Mark V system, the board is built

with industrial-grade components to match the system’s

durability—ensuring long-term compatibility with existing Mark V

installations and extending the lifespan of critical turbine

control infrastructure.

| DS200DTBBG1ABB | DS200TCCAF1BDF |

| DS200SDCIG2AFB | IS200ISBBG1AAB |

| DS200SDCIG2AHB | IS200CABPG1BAA |

| DS200BDAAG1AAA | IS200DSFCG1AEB |

| DS200SIOBH1ABA | IS200DRLYH1BBB |

|