| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Ring Rolling Machine |

|---|---|

| Brand Name: | Duolek |

| Place of Origin: | China |

| MOQ: | 1 Set |

| Price: | 14000-147000 USD Per Set |

| Payment Terms: | L/C,T/T |

| Delivery Time: | 45-75 Working Days |

| Packaging Details: | After Being Wrapped With Stretch Film, It Is Shipped Unpacked In The Container. |

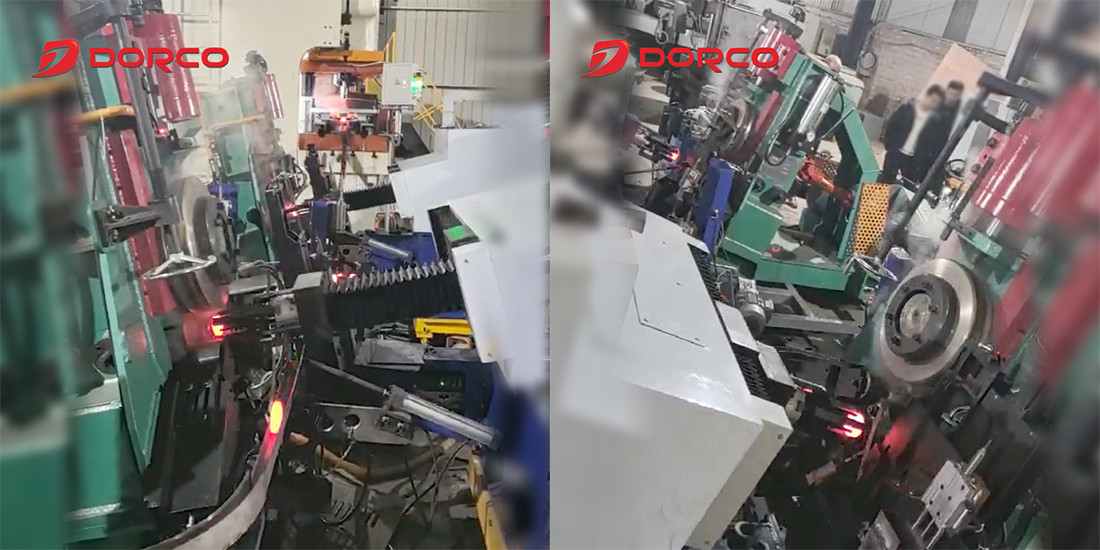

| Name: | Automated production line of ring rolling machine manipulator |

| Max. output: | 240 pieces/hour |

| forged rings: | 5KG-10KG |

| performance advantage: | Automatic counting, automatic detection |

| Equipment advantages: | Unmanned automatic operation |

| Equipment size: | customizable according to model |

| Company Info. |

| Shandong Dorco Heavy Machinery Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

The main components of the production line include a 650KW continuous induction heating furnace, a 400T closed press (three station design), and a 250E CNC ring rolling machine, each designed specifically for 5KG-10KG forging rings, with a maximum production capacity of 240 pieces/hour.

Its core performance advantages include:

Highly automated, achieving automatic counting, detection,

weighing, and decoration, effectively saving manpower;

Green and energy-saving, high precision, significant material

savings, in line with modern manufacturing green requirements;

Friendly human-computer interaction, stable automated production,

and strong equipment durability.

The automation system is fully configured, covering:

Single axis robot combined with slide table to achieve automatic

feeding of heating furnace rod materials to the press;

The four axis flat robot completes the three station workpiece flow

inside the press;

A single axis robot with an ejector mechanism is responsible for

unloading and waiting for materials from the press;

The dual robot mobile platform provides automatic loading and

unloading support for the ring rolling machine;

KUKA 210 robot realizes automatic loading, unloading, and

palletizing of ring components;

Automatic waste conveying mechanism;

Mold cooling and cleaning device;

Raw material cooling conveyor line;

Stacking and pallet management system.

The system integrates real-time monitoring, production indicator

statistics, and equipment efficiency analysis, and clearly grasps

production dynamics through visual dashboards. If you are

interested in the automated production line of ring rolling

machines, please feel free to contact us at any time. We look

forward to providing you with detailed solutions and comprehensive

service support.

|