| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Gypsum Grinding Mill |

|---|---|

| Brand Name: | Hengcheng |

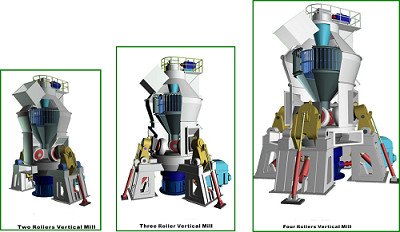

| Model Number: | HVM2500 HVM2800 HVM3400 HVM4200 HVM4500 HVM4800 HVM5100 HVM5600 |

| Certification: | ISO Patent Certificate High-Tech Product Certificate |

| Place of Origin: | CHINA |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 5 sets/month |

| Delivery Time: | 120 days |

| Packaging Details: | Standard shipping packaging |

| Name: | vertical roller mill for gypsum |

| Applicable materials: | Limestone, calcite, coal powder, slag, etc |

| Negative pressure system: | < 500 Pa (to prevent dust overflow) |

| Noise control: | ≤ 80 dB (customized soundproof cover) |

| After-sales Service Provided: | Engineers available to service machinery overseas, Online support |

| Degree Of Comminution: | fine grinding |

| Application Area: | Desulfurization, metallurgy, chemical industry, power, new energy |

| Installation: | Engineer Guide |

| Drive mode: | electrical machinery |

| Principle: | Vertical mill |

| Company Info. |

| Hefei Hengcheng Industrial Equipment Technology Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

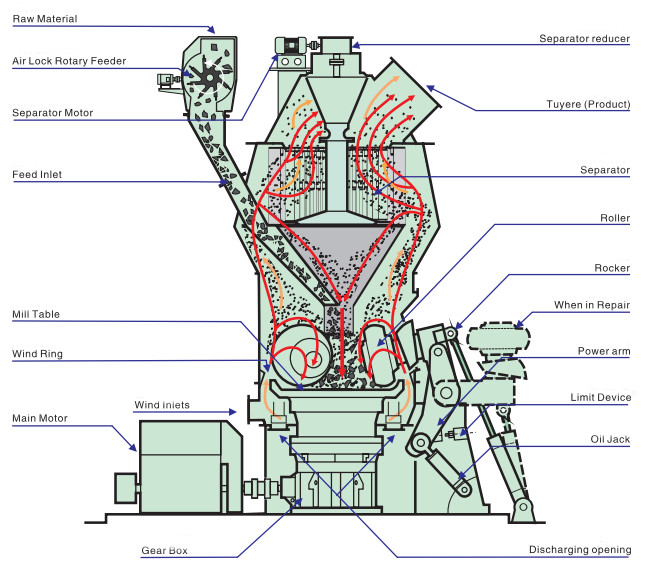

【Working Principle】

The motor drives the grinding disc to rotate through the reducer,

the material falls into the center of the grinding disc from the

feed inlet, and the hot air enters the mill from the air inlet.

Under the action of centrifugal force, the material moves to the

edge of the grinding disc, and is crushed by the grinding roller

when passing through the annular groove on the grinding disc. The

crushed material is carried by the high-speed airflow at the air

ring at the edge of the grinding disc, and the large particles fall

directly on the grinding disc. Re-grinding, when the material in

the airflow passes through the dynamic and static separator, under

the action of the rotating rotor, the coarse powder falls on the

grinding disc for re-grinding, and the qualified fine powder is

ground together with the airflow and collected in the powder

collecting device, which is product. Moisture-containing materials

are dried during contact with hot gas to achieve the required

product moisture.

Specifications And Technical Parameters Of HVM Gypsum Vertical Mill

| Model | HVM2500 | HVM2800 | HVM3400 | HVM3700 | HVM4200 | HVM4500 | HVM4800 | HVM5100 | HVM5600 |

| Grinding Table Median Diameter(mm) | 2500 | 2800 | 3400 | 3700 | 4200 | 4500 | 4800 | 5100 | 5600 |

| Capacity(t/h) | 85-100 | 130-160 | 190-240 | 240-300 | 320-400 | 400-500 | 440-550 | 550-670 | 600-730 |

| Raw Material Moisture | <10% | ||||||||

| Raw Meal Fineness | R0.08<12% | R0.08<14% | |||||||

| Raw Meal Moistrue | ≤1% | ||||||||

| Main Motor Power(kW) | 800/900 | 1120/1250 | 1800/2000 | 2500/2800 | 3150/3350 | 3800/4200 | 4200/4500 | 5000/5400 | 5600/6000 |

| Illustrate | Re:Raw materials bond index≤13kWh/t | ||||||||

Typical Application Scenarios

Production of Building Gypsum Powder Grind and calcine natural gypsum

or desulfurized gypsum into β-hemihydrate gypsum (building gypsum powder), which is used in gypsum boards, putty, etc.

Resource Utilization of Desulfurized Gypsum Desulfurized gypsum from power plants has high moisture content. The vertical mill

can simultaneously dry and grind it to produce raw materials for building materials.

Phosphogypsum Treatment Grind and modify phosphogypsum, a by-product of phosphochemical industry, for use as cement retarders

or subgrade materials.

|