| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

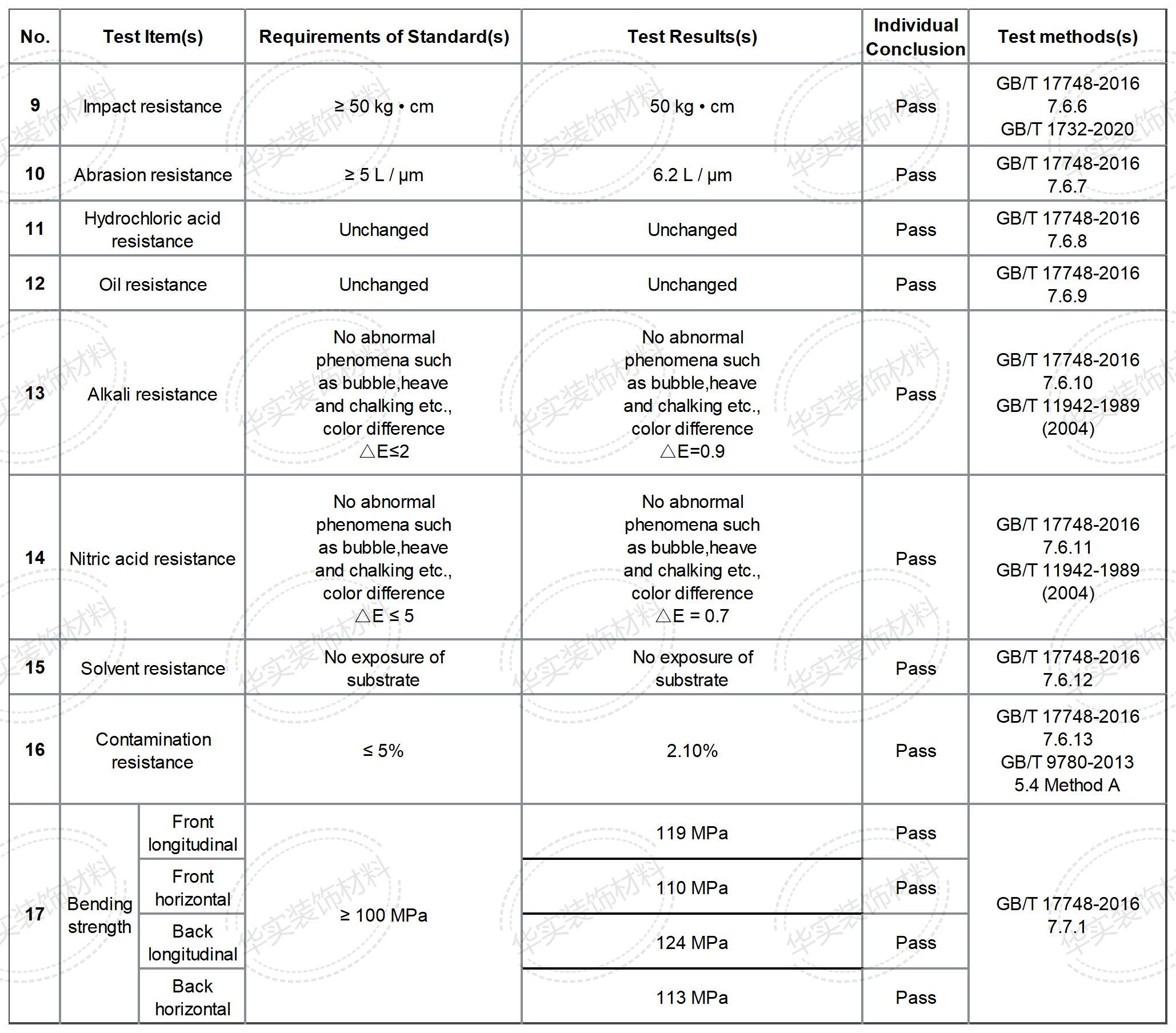

| Categories | Fire Rated ACP Sheets |

|---|---|

| Brand Name: | richly bound |

| Model Number: | FR ACP Sheets |

| Certification: | ISO 9001:2008;GB/T 17748-2016;GB 8624-2012 |

| Place of Origin: | CHINA |

| MOQ: | 500 sqm |

| Price: | depends on your needs |

| Payment Terms: | T/T |

| Delivery Time: | usually within 14 working days |

| Packaging Details: | Stacked one by one, with fiberboard as cushion |

| Sheet thickness: | 3.0-6.0mm |

| Aluminum layer thickness: | 0.12-0.5mm |

| Surface color: | Solid color,High gloss,Wood grain,Stone grain,Mirror finish,Brushed,Special effects |

| Application fields: | Exterior or Interior wall,balcony,ceilings,partitions,doors,column casings,equipment panels,interior decoration,interior design,furniture surfaces,Curtain walls,billboards,exhibitions,signs,signboard doors,coffee shop interior design |

| Surface coating: | Polyester (PE),High-performance polyester (HDPE),Fluorocarbon (PVDF),PVC film,Anodized |

| Size: | 1220mm * 2440mm,4ft * 8ft |

| Company Info. |

| Foshan Nanhai Huashi Decoration Material Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Founded in 1999, Foshan Nanhai Huashi Decoration Material Co., Ltd. has established itself as a trusted and experienced manufacturer in the aluminum composite panel (ACP) industry. Over the past two decades, we have consistently delivered premium ACP solutions to architects, contractors, and developers worldwide. Operating under the “Richly Bound” brand, our products are recognized for their high quality, safety compliance, and design versatility.

Our manufacturing facility is equipped with advanced continuous hot composite extrusion production lines, ensuring stable quality, high production efficiency, and the ability to handle large-scale orders with short lead times. We are among the first enterprises in China to achieve ISO 9001:2008 certification, and our production process strictly follows international quality management standards. Our long-term cooperation with clients in commercial, institutional, and residential projects across multiple countries has strengthened our position as a reliable ACP supplier in the global market.

The Fire Rated ACP Sheets with 4.0mm overall thickness, 0.3mm aluminum alloy layers on both sides, and PVDF fluorocarbon coating are engineered to meet the demanding requirements of modern exterior wall cladding systems. Designed for use in high-rise curtain walls, ventilated facades, and other outdoor architectural applications, these panels combine fire safety, weather durability, and aesthetic flexibility in one lightweight yet robust solution.

This product is particularly suitable for environments where strict fire codes, long-term exposure to weather, and visual consistency are critical factors—such as in high-rise commercial complexes, government facilities, transport hubs, educational institutions, and landmark buildings.

Safety is a non-negotiable requirement for exterior wall materials, and our Fire Rated ACP Sheets deliver certified performance:

A2 Fire Classification according to GB 8624-2012: A2-s1, d0, t0

Tested by the National Research Center of Testing Techniques for Building Materials

Non-combustible mineral-filled core with a low calorific value of 1.9 MJ/kg, far below the ≤3.0 MJ/kg standard

No flaming droplets or particles (d0) during combustion tests

Minimal smoke emission (s1) and ZA1 smoke toxicity rating, meeting indoor and outdoor safety requirements

Maintains structural integrity under high temperature conditions

With this fire rating, the panels are suitable for use in public buildings, high-occupancy structures, and regions with stringent building codes.

Total panel thickness: 4.0mm

Aluminum skin thickness: 0.3mm (front and back)

Core material: Non-combustible mineral-filled polyethylene alternative

Bending strength: up to 124 MPa

Peel strength: average 128 N·mm/mm, ensuring no delamination over time

Shear strength: 30.4 MPa

Thermal distortion temperature: 97°C, suitable for hot and cold climate regions

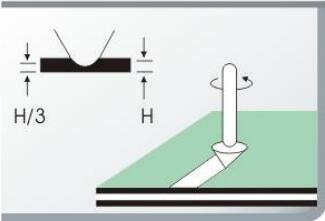

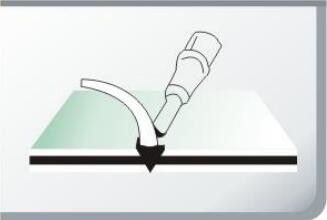

Flexibility: passes ≤2T bending test without coating cracks

Coating adhesion: Cross-cut rating 0, ensuring excellent coating durability

These structural properties mean the panel can withstand strong wind loads, making it ideal for high-rise and coastal applications.

Our Fire Rated ACP Sheets undergo strict accelerated aging and environmental exposure tests to ensure long-term reliability:

Resistant to extreme temperature fluctuations

No visible damage after prolonged humidity and water immersion tests

Passed contamination resistance test with only 2.1% surface change

Surface integrity maintained even after boiling water, nitric acid, and solvent exposure tests

Proven performance in saline coastal areas and industrial zones with high pollution levels

One of the major advantages of ACP is its excellent processability:

Can be cut, routed, folded, drilled, and bent without losing surface integrity

Supports complex shapes for corners, edges, and curved facade sections

Compatible with both mechanical fixing methods (rivets, bolts) and structural adhesives

Lightweight nature reduces structural load and speeds up installation on site

Can be pre-fabricated in workshops to minimize construction time

The combination of fire safety, weather resistance, and versatile aesthetics makes this product suitable for:

High-rise building facades

Curtain wall systems for commercial and office towers

Public infrastructure projects: airports, train stations, exhibition centers

Institutional buildings: universities, hospitals, government offices

Retail and hospitality exteriors: shopping malls, hotels, resorts

Renovation projects: upgrading old building facades with modern finishes

Compared to stone, ceramic tiles, or solid aluminum sheets, Fire Rated ACP Sheets offer:

Significant weight reduction – approximately 60% lighter than solid aluminum, reducing structural costs

Improved safety – certified non-combustible performance

Lower maintenance requirements – PVDF coating reduces cleaning frequency

Design flexibility – supports large panel sizes and multiple surface finishes

Cost efficiency – easier transportation and faster installation

The Fire Rated ACP Sheets 4.0mm Thickness with 0.3mm Aluminum Layer, PVDF Coated are purpose-built for exterior wall applications where performance, safety, and aesthetics must work together. Backed by A2 fire certification, proven mechanical strength, and over 20 years of weather resistance, this panel provides architects, developers, and contractors with a reliable and visually appealing cladding solution.

Whether for new builds or renovation projects, these panels deliver long-term value, compliance, and design freedom—making them an investment that enhances both safety and visual impact.

For full technical data sheets, sample requests, or project-specific quotations, please contact our sales team.

|