| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Vibratory Screening Machine |

|---|---|

| Brand Name: | EVERSUN |

| Model Number: | EXZS |

| Certification: | ISO,CE |

| Place of Origin: | CHINA |

| MOQ: | 1set |

| Price: | negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, MoneyGram, Western Union |

| Supply Ability: | 5000set/year |

| Delivery Time: | within 7-15 work days |

| Packaging Details: | Standard export wooden cases |

| Power Consumption: | Varies depending on model |

| Noise Level: | Less than 75 decibels |

| Driving Force: | Electricity |

| Mesh Size: | 2-500mesh |

| Shape: | round |

| Key Words: | Vibrating Screen |

| Surface Treatment: | Mirror polishing and polishing |

| Layer: | 1~5layer |

| Power Source: | Electric |

| Material: | Stainless Steel |

| Installation Method: | Floor-mounted or suspended |

| Company Info. |

| EVERSUN Machinery (Henan) Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Product description

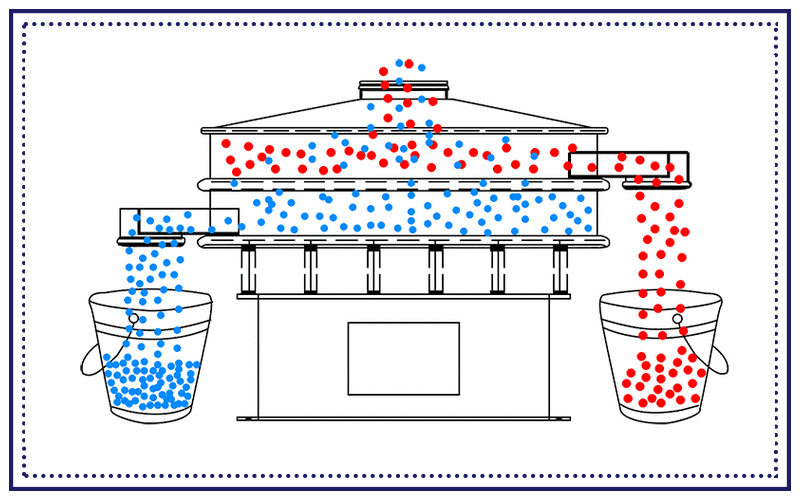

Rotary vibrating screen, as an efficient screening equipment, plays a key role in many industries. It is mainly composed of screen frame, vibrator, screen and shock absorber. When working, the upright motor is used as the excitation source, and the eccentric weight at both ends of the motor cleverly transforms the rotating motion into horizontal, vertical and inclined three-dimensional motion, which is transmitted to the screen surface. By adjusting the phase Angle, the material movement trajectory can be accurately controlled.

Working principle

Rotary vibrating screen is commonly used screening equipment, which

is composed of screen frame, vibrator, screen mesh and shock

absorber. It takes the upright motor as the excitation source, and

the eccentric weight at the upper and lower end of the motor

generates centrifugal force when rotating, which converts the

rotating motion of the motor into horizontal, vertical and inclined

three-dimensional motion, and transmits it to the screen surface.

By adjusting the phase Angle of the eccentric weight, the movement

path of the material on the screen surface can be changed, and the

material can be fully contacted with the screen to achieve

efficient screening.

The equipment has high screening efficiency, can handle powder,

particles, mucus and other materials, the accuracy of 500 mesh or

0.028mm, the screen is not easy to block. It is convenient to

change the network, and it can be completed in 3-5 minutes by using

the sub-parent network frame. Fully closed design to avoid material

flying and impurities mixed, and equipment stable operation, small

size, light weight, easy to move, discharge port direction can be

flexibly adjusted, widely used in chemical, food, mining and other

fields.

Features & Benefits

High screening efficiency: It can quickly handle powder, particles and mucus materials to ensure efficient operation.

High screening accuracy: accuracy up to 500 mesh (0.028mm), to meet the requirements of high material fineness industry.

Screen is not easy to clog: reduce downtime and cleaning time to ensure continuous production.

Convenient network change: The use of mother-and-child network frame, 3-5 minutes to complete the screen replacement, improve maintenance efficiency.

Fully enclosed structure: avoid material flying, prevent dust pollution of the environment, and eliminate external impurities from mixing with the material.

Easy to move and flexible discharge port: small size, light weight, easy to adjust the position in the workshop or transfer in different sites; Discharge port direction can be adjusted as needed to adapt to a variety of production line layouts.

Product parameter

| Model | Equipment diameter | Power(KW) | Deck | Effective screening area(m2) | Screen mesh |

| EXZS-600 | 600mm/24inch | 0.25 | 1-5 | 0.2289 | 20 microns to 20 mm |

| EXZS-800 | 800mm/32inch | 0.55 | 0.4183 | ||

| EXZS-1000 | 1000mm/40inch | 0.75 | 0.6359 | ||

| EXZS-1200 | 1200mm/48inch | 1.1 | 0.9499 | ||

| EXZS-1500 | 1500mm/60inch | 1.5 | 1.5386 | ||

| EXZS-1800 | 1800mm/70inch | 3 | 1-4 | 2.2687 | |

| EXZS-2000 | 2000mm/78inch | 4.5 | 2.8893 |

Design Drawing Display

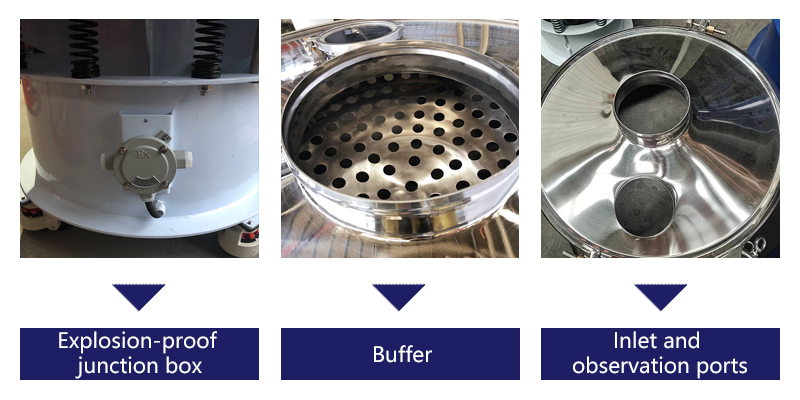

Detail display

Application

Packaging & Shipping

Why Choose us

About us

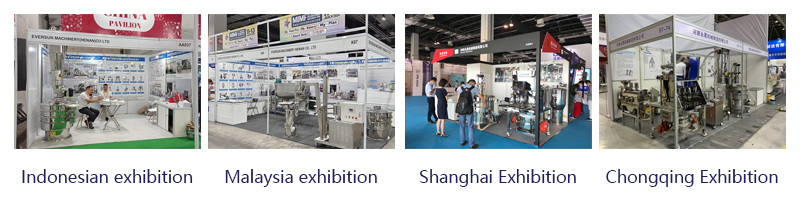

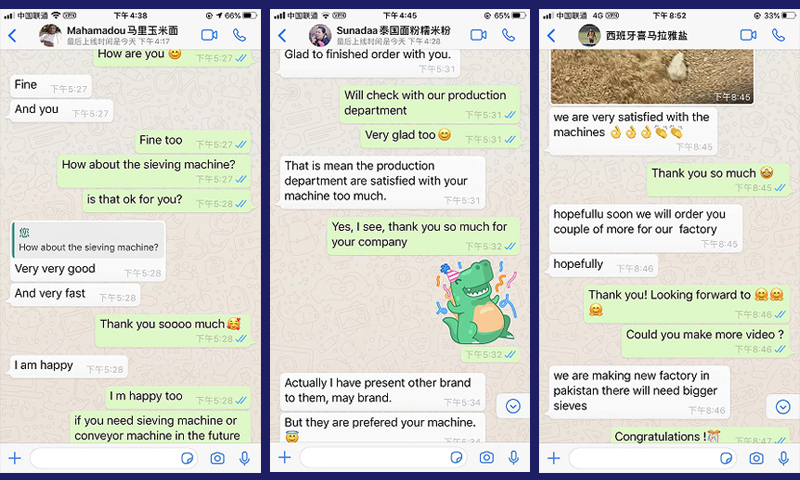

We have been specializing in the production of Screening and

conveying equipment for 13 years. China's vibrating screen industry top three. And we have done

matching and OEM for many large companies. Including the world's top vibrating screen manufacturer,

Sweco, USA, we have OEM

for his China region. And our products are often exported to

Australia, Thailand, Indonesia, New Zealand and other countries.

We welcome customers or dealers to visit our factory and will

arrange everything for you.Our factory address: West of the industrial and commercial office of Da

Zhaoying Town, Xinxiang City, Henan Province.

|