| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Big Bag packing machine |

|---|---|

| Brand Name: | EVERSUN |

| Model Number: | SYH |

| Certification: | ISO,CE |

| Place of Origin: | CHINA |

| MOQ: | 1set |

| Price: | negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, MoneyGram, Western Union |

| Supply Ability: | 5000set/year |

| Delivery Time: | within 7-15 work days |

| Packaging Details: | Standard export wooden cases |

| Type: | Weighing-type Filling Machine |

| Packaging Accuracy: | ±0.2% |

| Packaging Product: | Layers Pellets , Canary Seed |

| Suitable For Material: | Granular / Powder / flake materials |

| Metering Mode: | Gross weighing mode |

| Function: | Big Bag Weighing Filling Packing |

| Operation: | Automatic |

| Driven Type: | Electric, Pneumatic |

| Operating Interface: | Touch screen |

| Company Info. |

| EVERSUN Machinery (Henan) Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

![]()

The ton bag packaging machine is a versatile "all-rounder" in the

industrial

packaging field, seamlessly integrating a series of key functions such as

conveying, precise metering, rapid filling, and strict sealing. Whether it's powder

raw materials in the mining and chemical industries or granular materials such as

grain feed, it can be accurately and error-free filled into ton bags. It has extremely

flexible speed control and can be adjusted at any time according to the production

rhythm; electrical control system is stable and reliable, and the operation is

worry-free; the unique dust-proof design effectively purifies the working

environment, is environmentally friendly and efficient, greatly improves the

efficiency and quality of packaging.

![]()

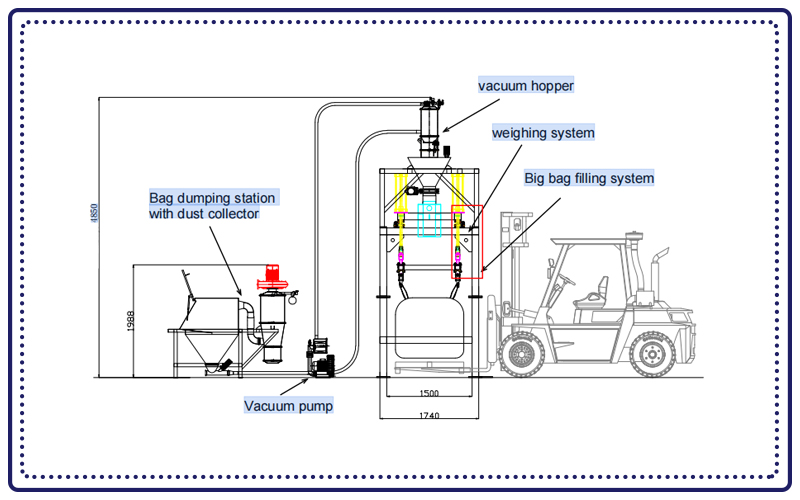

When the ton bag packaging machine is working, the materials are

conveyed to

the feed port through spiral conveyors, belt conveyors, etc., the silo or storage

equipment, and then enter the weighing hopper equipped with a weighing sensor.

The control system compares the weight signal transmitted by the sensor with the

value to achieve precise metering. After the ton bag is fixed and centered on the

pneumatic or electric suspension device, the materials with good fluidity flow into

the bag by gravity from the hopper, and those with poor fluidity are filled by

pneumatic conveying. After the filling is completed, the ton bag is conveyed to

sewing station by the conveying device, where the bag opening is sewn by the

industrial sewing machine according to the preset parameters. The whole process

is precisely controlled and coordinated the control system with the programmable

logic controller (PLC) as the core, and the operators can set the parameters and

monitor the operation of the equipment through the-machine

interface.

![]()

1. Precise metering: Equipped with high-precision weighing sensors

and

advanced metering control systems, it can accurately control filling weight of

materials, keeping the weight error of each ton bag within a very small range,

ensuring the accuracy and consistency of packaging weight.

2. Accurate positioning The ton bag hanging and centering device can ensure that

the ton bag is accurately positioned during filling and sewing, avoiding material

spillage and bag mouth sewing deviation, and packaging quality.

3. Dust-proof design: It is usually equipped with complete dust prevention and dust

removal devices, such as suction hoods and dust collectors, which can collect and

handle dust during material conveying and filling, reduce dust leakage, and reduce

dust pollution in the production environment, protecting the health of operators and

the production environment.

4. Low noise operation: In the process of equipment design and manufacturing, a

series of noise reduction measures have been taken, such as selecting low-noise

motors, and other components, optimizing the mechanical structure, and reducing

the noise of equipment operation, creating a relatively quiet working environment

for operators.

5. Convenient maintenance: The equipment a reasonable structural design, compact

layout of various components, easy disassembly and installation, and convenient

daily maintenance and maintenance work for operators, reducing the difficulty and

cost of maintenance.

![]()

Powder: Quantitative packaging of medicines, chemicals, pesticides,

rubber, non-metallic

materials, coatings, ceramics, etc. Such as ceramic, calcium

carbonate, wettable powder,

carbon black, rubber powder, food additives, pigments, dyes, zinc

oxide, medicines, etc.

Granules Medicines, fine chemical particles, plastic particles, PET

polyester, rice, feed,

compound fertilizer, etc.![]()

| Model | DCS - 1000 | |||

| Packing Material | Wooden Boxes | |||

| Gross Weight | 1640 KG | |||

| Packing Capacity | 8- 40 bags / h (It depends on the material characteristics and net weight) | |||

| Packaging error | ≤± 0.2% | |||

| Weighing Range | 300 - 2000 Kg / bag, customized needs | |||

| Working air pressure | 0.4 ~ 0.7MPa | |||

| Application Materials | Bulk bag packing machine is suitable for all kinds of material, such as chemical, food, feed, hardware, building materials etc. | |||

![]()

![]()

![]()

![]()

![]()

Company Profile

|