| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | PP Strap Making Machine |

|---|---|

| Brand Name: | JIATUO CHINA |

| Model Number: | JTPP-90 |

| Certification: | IS CEO |

| Place of Origin: | CHINA |

| MOQ: | 1 SET |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T |

| Delivery Time: | 30-40days |

| Packaging Details: | plastic film |

| Strap Color: | Single/Multi-Color |

| Strap Speed: | >260m/min |

| Strap Core Diameter: | 406*150mm / 200*180mm |

| Strap Thickness: | 0.4-1.2mm |

| Strap Tension: | Adjustable |

| Strap Width: | 5-19mm |

| Power Supply: | 380V/220V |

| Exchange Filter: | Fully Automatic |

| Screw Size: | Single and Double screw |

| Production Capacity: | 2.8T-12T/24hours |

| Company Info. |

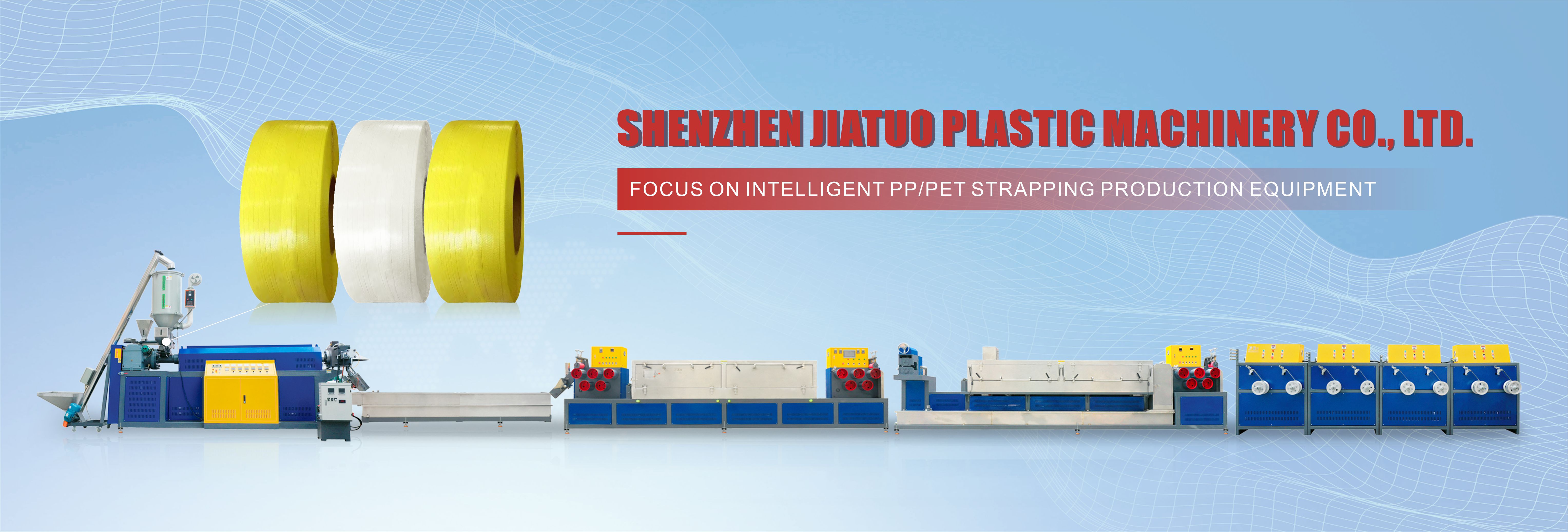

| SHENZHEN JIATUO PLASTIC MACHINERY CO.,LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

380kg/H Capacity PP Belt Strapping Extruder Production Line With 5-19mm Customized

Specification of PP straps double output making machine

| Item | Product name | Detailed parameters |

| 1 | Materials | PP polypropylene new material/recycled material |

| 2 | Product | PP strap |

| 3 | Capacity | 120-150kg/h |

| 4 | Total install power | 80kw, (Operating power 50-55%) |

| 5 | Strap width | 5mm-19 mm |

| 6 | Thickness | 0.4 mm-1.2 mm |

| 7 | Manpower | 1-2person/shift |

| 8 | Workshop required | L (28m) ×W (2m) ×H (4m) |

| 9 | Power source | 380V, 50Hz, 3Phase |

| 10 | Electric components | Schneider |

| 11 | Inverter | INVT |

| 12 | Switches+Thermostat | Taiwan Fotek |

| 13 | Motor power | Gugao |

| 14 | Solid state relay | Taiwan Fotek |

| 15 | Bearing | FSB |

1. Mainly for making PP strapping, which is widely use in packing industry, for example: cartons, fruit, agriculture industry etc.

2.The raw material can be 100% recycled material, which can reduce the Pproduce cost and get a good profit.

3.The PP bale is the substitution of the steel strap and has a lot of advantages such as good extension, high temperature resistant, easy use.

1. Production of raw materials can be used to produce packaging

belts with recycled materials or mixed new materials. It is also possible to add calcium carbonate according to customer

conditions to reduce production costs, increase product profit, and

market competitiveness.

2. The output is high, and the finished line speed can reach 260m/min.

3. The appearance of the whole machine has been optimized, beautiful and high-grade, durable and durable.

4. High-precision die parts make the product forming quality stable,

width and thickness fluctuations are far less than the national standard; unique network changing

device greatly reduces the network changing time.

5. High-precision high-quality screw, using well-known brand, unique parameter design, with the

advantages of large extrusion, good plasticization, high hardness

and high wear resistance.

Application of PP strapping

PP packing strap, also known as PP plastic belt, is a world widely

used new type package material substitute for steel belt.

With years development on it and decrease on cost, it is now widely used in steel industry, chemical fiber industry, Aluminum

industry, paper industry, Brick ceramics, Screw industry, tobacco

industry, electric industry, textile industry and wood industry.

It is most widely used steel belt substitute with high strength.

FAQ

|