| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Stainless Steel Pipe |

|---|---|

| Brand Name: | DELTA |

| Model Number: | 201 304 316L 321 310S 314 347 2205 2507 904L.etc |

| Certification: | ISO |

| Place of Origin: | China |

| MOQ: | 500 kgs |

| Price: | 2400 - 3500 USD/Ton |

| Payment Terms: | T/T, Western Union, L/C |

| Supply Ability: | 10 Ton per week |

| Delivery Time: | 5 - 12 days based on the quantity |

| Packaging Details: | standard packing for export |

| Products: | BA Stainless Steel Pipe |

| Grade: | 304 316L 321 2205 310S 904L.etc |

| Standard: | ASTM GB EN |

| Length: | 6m or as request |

| Diameter: | 6 - 219mm or as clients request |

| Wall thickness: | 0.4 - 8.0mm |

| Type: | seamless pipe |

| Service: | cutting |

| Other Shape: | square, rectangle |

| Company Info. |

| JIANGSU MITTEL STEEL INDUSTRIAL LIMITED |

| Verified Supplier |

| View Contact Details |

| Product List |

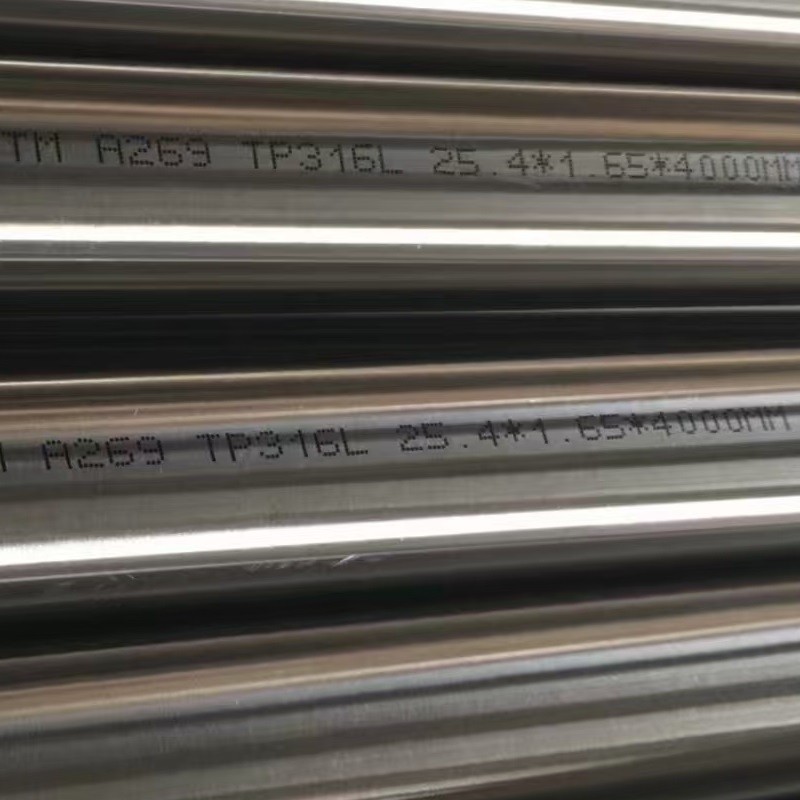

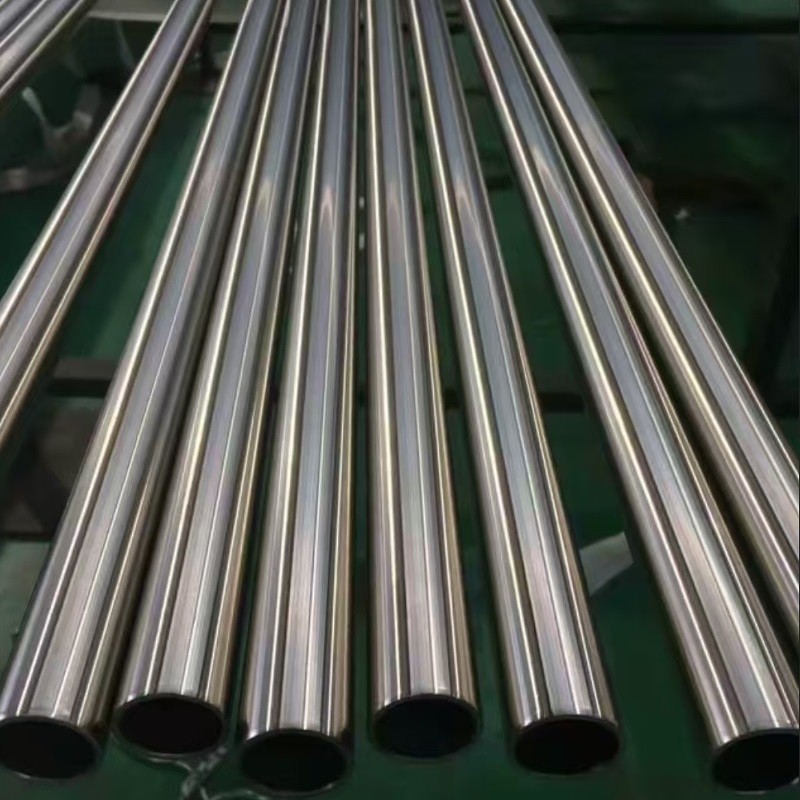

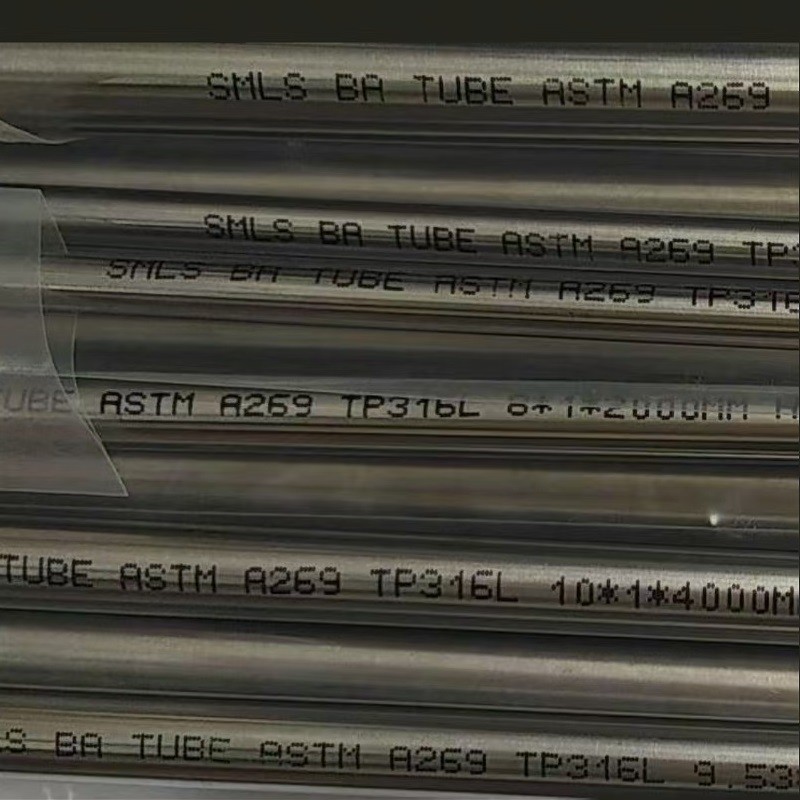

Bright Annealed Seamless BA Stainless Steel Pipe TP316L Small Diameter BA Pipe

Products Specification

| Standard | ASTM A213, ASTM A269, ASME SA213, ASME SA269 |

| Pipe Type | Bright Annealed Stainless Steel Tubing |

| Grades | 304, 304L, 316, 316L, 321, 310S, 2205, 2507 |

| Dimensions | Outer Diameter (OD): 1.00 mm to 76.2 mm |

| Wall Thickness | 0.2 mm to 6.0 mm |

| Length | Up to 12 meters (custom lengths available upon request) |

| Manufacturing Process | Cold Drawn, Bright Annealed, Seamless |

| Material Surface Finish | Bright Annealed (BA), Mirror Polished, No. 4 Finish |

| End Type | Plain End (PE), Beveled End (BE), Threaded End (TE) |

| Certifications | ISO 9001, EN 10204 3.1 / 3.2, PED, ASME |

High purity ba/ep tubing Pipe, length 6 meters

| Imperial size | Metric size | ||

| OD inch | WT inch | OD mm | WT mm |

| 1/8 (0.125) | 0.028 | 3.18 | 0.71 |

| 0.035 | 3.18 | 0.89 | |

| 3/16 (0.188) | 0.028 | 4.76 | 0.71 |

| 0.035 | 4.76 | 0.89 | |

| 0.049 | 4.76 | 1.24 | |

| 1/4 (0.250) | 0.035 | 6.35 | 0.89 |

| 0.049 | 6.35 | 1.24 | |

| 0.065 | 6.35 | 1.65 | |

| 0.083 | 6.35 | 2.11 | |

| 3/8 (0.375) | 0.035 | 9.53 | 0.89 |

| 0.049 | 9.53 | 1.24 | |

| 0.065 | 9.53 | 1.65 | |

| 0.083 | 9.53 | 2.11 | |

| 1/2 (0.500) | 0.035 | 12.7 | 0.89 |

| 0.049 | 12.7 | 1.24 | |

| 0.065 | 12.7 | 1.65 | |

| 0.083 | 12.7 | 2.11 | |

Tubing length up to 32,808 feet (10,000 m) For control line, chemical injection line

Available materials

Dimension Tolerance

ASTM A269 / ASME SA269 | ||

| Size OD | Tolerance OD | Wall thickness |

≤1/2" 1/2 | ±0.005" ±0.005" | ±15% ±15% |

1. To decrease welds is to improve safety.

2. Coiled Stainless Steel Tubing doesn’t need welds, so can save users more construction time than using traditional strength tubing.

3. Coiled Stainless Steel Tubing is pliant which helps to decrease welding spatters and keep material clean.

4. Coiled Stainless Steel Tubing is seamless, and all have passed pressure test which reduce the risk of leakage.

5. It’s easy to pack, facilitates storage and shipping.

6. Seamless coil tubing reduce scraps.

|