| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Carbon Fiber Tube |

|---|---|

| Brand Name: | Tanku |

| Model Number: | OEM |

| Certification: | SGS, ROHS |

| Place of Origin: | China |

| MOQ: | Negotiable |

| Price: | Negotiable |

| Payment Terms: | T/T, Western Union, L/C |

| Supply Ability: | 1500pcs month |

| Delivery Time: | 7 working days after receiving Order Pay |

| Packaging Details: | Normal Corrugated Carton Packing for International Shipment |

| Product Name: | Roll Wrapped Carbon Fiber Tube |

| Shape: | Round/Oval or customized |

| Dimension Tolerance: | +- 0.1mm |

| Surface Finish: | Matte / Glossy / Natural Twill |

| Weight: | 60g/m |

| Density: | 1.5g/cm3 |

| C Content (%): | 100% |

| Resin System: | Epoxy or high-temperature resin |

| Company Info. |

| SHANGHAI LIJIN IMP.&EXP. CO.,LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

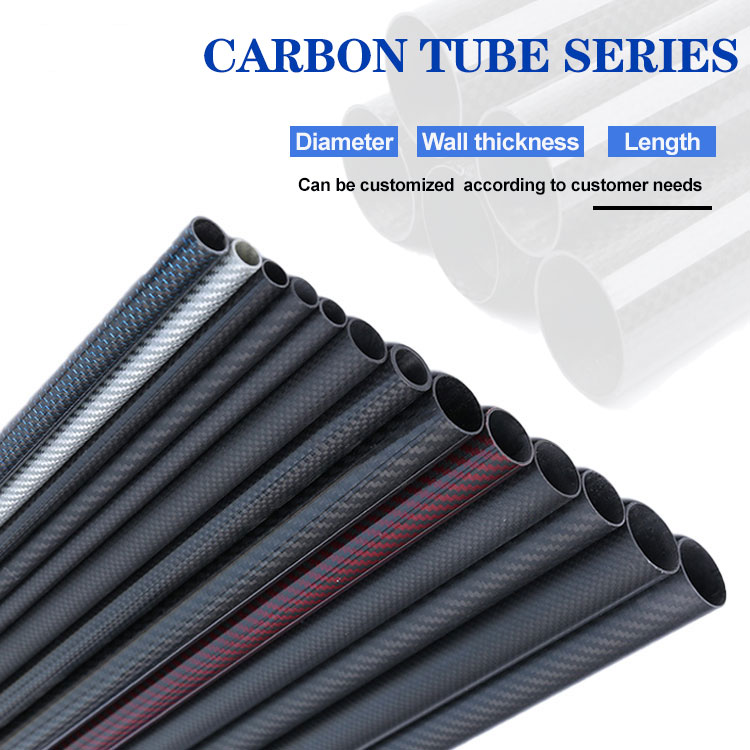

Durability & Flexibility Customizing Roll Wrapped Carbon Fiber Tube for Your Industry

What is a Roll Wrapped Carbon Fiber Tube?

Roll wrapping is a precision manufacturing process where carbon fiber pre-preg (resin-impregnated sheets) is wrapped around a mandrel in specific orientations (0°, 45°, 90°), then cured under heat and pressure. This results in high-performance tubes with superior consistency and strength compared to pultruded or filament-wound tubes.

Roll wrapping is a popular manufacturing technique for producing high-strength, lightweight carbon fiber tubes. This method involves wrapping pre-impregnated carbon fiber sheets (prepreg) or wet-laid fibers around a mandrel in a helical or hoop pattern, followed by curing to create a rigid, hollow structure. Roll-wrapped carbon fiber tubes are widely used in aerospace, automotive, sporting goods, and industrial applications due to their excellent strength-to-weight ratio and stiffness.

Manufacturing Process

1. Material Preparation

2. Roll Wrapping Process

3. Curing

4. Post-Processing

Advantages of Roll-Wrapped Carbon Fiber Tubes

Roll-wrapped carbon fiber tubes offer superior performance in weight-sensitive applications. Their customizable manufacturing process allows for tailored mechanical properties, making them a preferred choice in high-tech industries.

Whether you're building a next-gen drone, a robotic gripper, or a carbon racing bike, custom roll wrapped carbon fiber tubes give you the edge in performance, weight savings, and design precision. Partnering with a skilled manufacturer means turning your unique specs into industry-leading results.

Service

|