| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | PVC Core Sheet |

|---|---|

| Brand Name: | MK |

| Model Number: | MOP-W |

| Place of Origin: | China |

| MOQ: | 30000 sheets or 2 tons |

| Price: | Negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 10 million square meters per month |

| Delivery Time: | 10-15 working days |

| Packaging Details: | 50 or 100 or 200 sheets per bag, 10 bags per paper carton, and the cartons are piled up and firmly fixed on solid plywood pallets |

| Material: | PVC |

| Thickness: | 120micron to 760micron |

| Color: | Milk White and Snow White or Pure White ADE |

| Suitable printer models: | The whole series of offset printer |

| Vicat ℃: | 77±2 |

| Loading Port: | Shanghai or other Chinese port |

| Company Info. |

| MKarte Material Technology (Tianjin) Limited |

| Verified Supplier |

| View Contact Details |

| Product List |

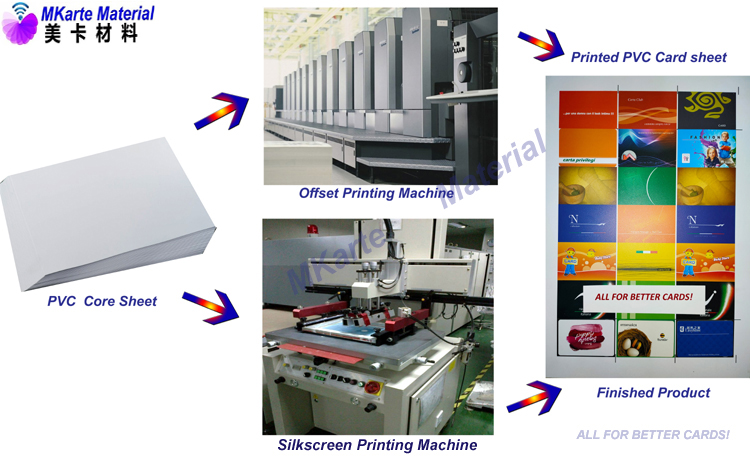

Heidelberger Printable Sheet White Offset Printing Plastic Core Sheet 0.30mm For Bank Card Production

1.Introduction of Heidelberger Printable Sheet White Offset

Printing Plastic Core Sheet 0.30mm For Bank Card Production

This kind of ordinary PVC sheet can be used for laminating,

non-laminating, printing, coating and

cutting, such as membership cards and calendars.

Offset printing sheets MOP series are designed for offset printer and silk screen printer use. They can also be used as non-printed middle core sheet.

2. Features of Heidelberger Printable Sheet White Offset Printing Plastic Core Sheet 0.30mm For Bank Card Production

Offset printing sheets MOP series are designed for offset printer

and silk screen printer use. They can also be used as non-printed

middle core sheet. They are massively used by many card factories

worldwide.

1) Suitable for the whole series of offset printer and silk screen

printer.

2) High definition images.

3) Excellent ink adhesion with strong peeling strength after

lamination.

4) No crack occurs on the printed images after lamination at high temperature.

Technical parameters:

| Item | Index | |

| Tensile strength | Longitudinal MPa | ≥45 |

| Transverse MPa | ≥40 | |

| Vicat ℃ | 77±2 | |

| Surface Tension dyne/cm | ≥35 | |

| Heat shrinkage rate% 140℃ 10min | Transverse ≤5 | |

| Longitudinal ≥-10 | ||

| Squareness mm | ±1 | |

| Thickness tolerance % | ±5 | |

| Roughness μm | Ra,μm | 0.7~1.4 |

| Rz,μm | 4~9 | |

3. Product Advantage of Heidelberger Printable Sheet White Offset Printing Plastic Core Sheet 0.30mm For Bank Card Production

1. Smooth and Uniform Surface

It is waterproof and has very good smooth surface, and is non-deformable.

2. Reliable Electrical Insulation

It is widely used for different electrical equipment.

3. Excellent Chemical and Corrosion Resistance

It can withstand the erosion of a variety of chemicals.

4. Good Impact Resistance

It has good impact resistance, pressure-resisting and durability.

5. Easily Formed

It is easily formed due to good plasticity, which is suitable for die cutting, vacuum forming and folding.

6. Wide Usage

It can be laminated with uncoated overlay film after uv offset priting or screen printing.

|