| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Bronze Bushing Material |

|---|---|

| Brand Name: | VIIPLUS |

| Model Number: | Wear Strip Graphite |

| Certification: | MET ISO, NAAMS, JIS and many automotive and appliance manufacturers' standards |

| Place of Origin: | Plain Bearing Material |

| MOQ: | 100 Piece/Pieces (Min. Order) |

| Price: | flat strip material inch sizes Manufacturers,Factory Price |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 5000000 Piece/Pieces One week |

| Delivery Time: | 4 - 12 BUSINESS DAYS |

| Packaging Details: | EXPORT CARTON WOOD PALLET WOODEN CASE |

| Material: | Bronze C86300,Self Lubricating Products |

| Wear Plate: | Self Lubricating |

| Size: | Metric & Inch |

| Bushing & Wear Plate Application: | Die and mold components |

| Bearing Bushing Factory Price: | tiffany@viiplus.com |

| Self-lubricating Bearing Bushing Manufacturer: | https://www.viiplus.com/ |

| Bush Bearings Manufacturers Suppliers Exporters: | plain bearings. Long, maintenance-free service, manufactures bushings in various designs and from different materials. tiffany@viiplus.com, Bushings - Configure and purchase - https://www.viiplus.com/ |

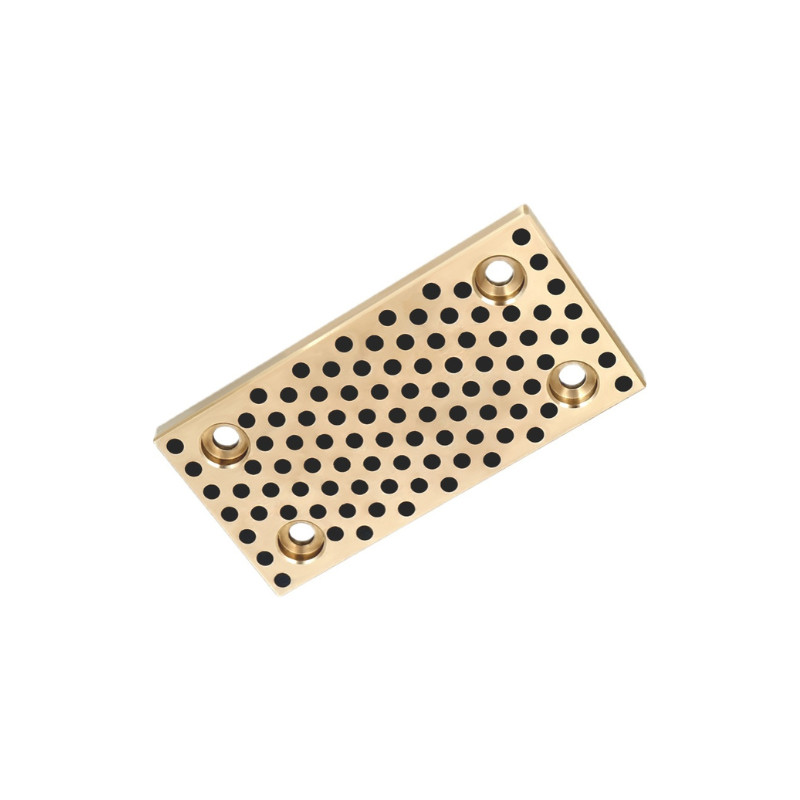

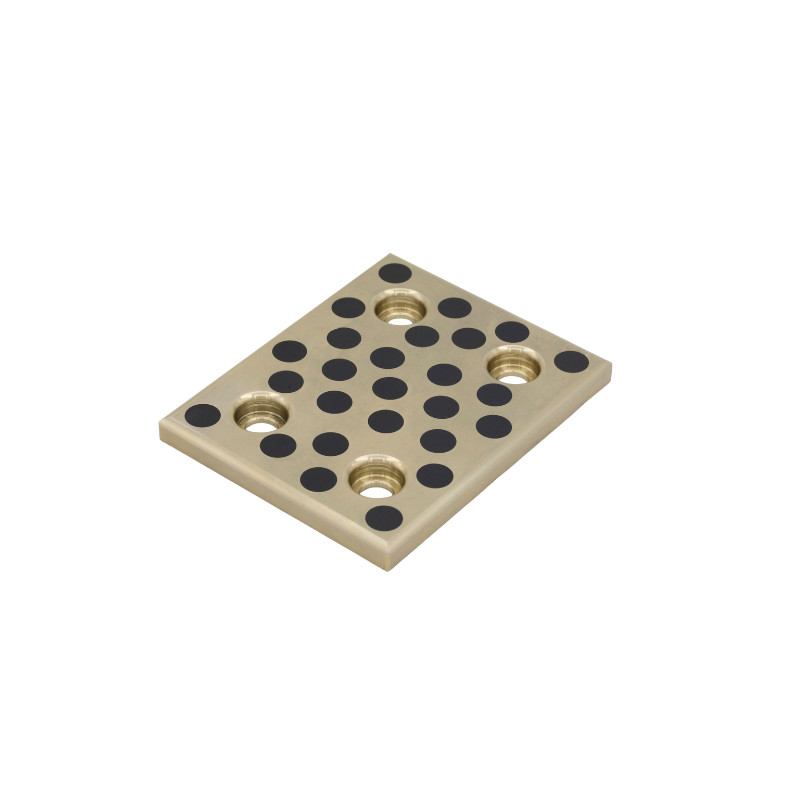

When discussing wear plate strip, graphite plugs, and metal bronze (specifically Bronze C86300), China has become a major supplier in these areas. Bronze C86300, also known as tin bronze, is a type of metal bronze alloy that is highly resistant to corrosion and wear. It is commonly used in applications where durability and strength are crucial, such as in bearings, bushings, and other mechanical components.

Wear plate strip is a type of material that is specifically designed to resist wear and abrasion. It is often used in industrial applications where components are subjected to friction and wear, such as in mining equipment, construction machinery, and other heavy-duty applications.

Graphite plugs, on the other hand, are components that are made from graphite, a natural mineral that is known for its excellent thermal and electrical conductivity. Graphite plugs are commonly used in high-temperature applications, such as in furnaces and kilns, where they help to maintain the temperature and provide protection against corrosion.

China has become a leading supplier of these materials due to its advanced manufacturing capabilities and competitive pricing. Many Chinese manufacturers have specialized in the production of wear plate strip, graphite plugs, and metal bronze, including Bronze C86300, and are able to provide high-quality products that meet the demands of customers worldwide.

In summary, wear plate strip, graphite plugs, and metal bronze (especially Bronze C86300) are essential materials in various industrial applications. China's supply of these materials, thanks to its manufacturing prowess, has made it a reliable source for customers around the world.

L-Gibs & V-Gibs Bronze-Plated, Inch, L-Gibs Solid-Bronze,

Self-Lubricating, Inch,Solid-Bronze, Self-Lubricating,

Metric,Square Gibs,Gib Assemblies,Wear Strip Ways,

Self-Lubricating,Guide Blocks,U & V Blocks dimensions.Included in

our full line offering are both inch and metric size die components

that are designed to die standards.Advanced in design, each product

is measured to precise standards and is distortion-free for

reliable performance and excellent wearability.

including ISO, NAAMS, JIS and many automotive and appliance

manufacturers' standards. The complete bushing & wear plate

offering includes:

Check our website www.bronzegleitlager.com for the latest technical information.

Bronze-Plated SteelWith and without graphite plugs

Standard L-Gibs with and without mounting holes

High quality Self-Lubricating L-Gibs with and without mounting

holes

Bronze with Self-Lubricating Graphite Plugs

Contact VIIPLUS Customer Service for hole pattern,made to order wear plate

■Plastics Injection Molds

■Special Machines

■Press Gibbing

■Special Slide Applications

Standard wear strips are plated

on one side only.Up to four sides can be plated.Please call for

quotation.

Wear Strips – Inch – Fixed-Length,in a wide variety of applications, including lifter slides in molds,Mounting hole patterns for Wear Strips

■ Bronze with self-lubricating graphite

plugs for bilateral wear

■ Ready to use

■ Solid Bronze available upon request

| Chemical Requirements | ||||||||||||

| Copper Alloy UNS No. | Composition, % max, except as indicated | |||||||||||

| Nickel | ||||||||||||

| Copper | Tin | Lead | Zinc | Iron | Including | Aluminum | Manganese | Antimony | Sulfur | Phosphorus | Silicon | |

| Cobalt | ||||||||||||

| C86300 | 60.0–66.0 | 0.20 | 0.20 | 22.0–28.0 | 2.0–4.0 | 1.0A | 5.0–7.5 | 2.5–5.0 | ... | ... | ... | ... |

| C90500 | 86.0–89.0 | 9.0–11.0 | 0.30 | 1.0–3.0 | 0.20 | 1.0A | 0.005 | ... | 0.20 | 0.05 | 0.05B | 0.005 |

| C91100 | 82.0–85.0 | 15.0–17.0 | 0.25 | 0.25 | 0.25 | 0.50A | 0.005 | ... | 0.20 | 0.05 | 1.0B | 0.005 |

| C91300 | 79.0–82.0 | 18.0–20.0 | 0.25 | 0.25 | 0.25 | 0.50A | 0.005 | ... | 0.20 | 0.05 | 1.0B | 0.005 |

| C93700 | 78.0–82.0 | 9.0–11.0 | 8.0–11.0 | 0.8 | 0.7C | 0.50A | 0.005 | ... | 0.50 | 0.08 | 0.10B | 0.005 |

| A In determining copper minimum, copper may be calculated as copper plus nickel. | ||||||||||||

| B For continuous castings, phosphorus shall be 1.5 % max. | ||||||||||||

| C Iron shall be 0.35 % max. when used for steel-backed. | ||||||||||||

| NO. | DIN | Material No. | Designation | ASTM Standard | Proportional | Density (g/cm³) | 0.2% Strain (MPa) | Tensile Strength (MPa) | Strain (%) | E-modulus (MPa) | Hardness (HB) | Applications |

| 1 | 1705 | 2.1090.01 | CuSn7ZnPb | B 584 | Cu 81 - 85, Sn 6 - 8, Zn 3 - 5, Pb 5 - 7 | 8.8 | 120 | 240 | 15 | 106,000 | 65 | Widely utilized in automotive, aerospace, and marine engineering for components requiring good strength and corrosion resistance. Recognized internationally for versatility and performance. |

| 2.1090.03 | CuSn7ZnPb | B 271 | Cu 81 - 85, Sn 6.3 - 7.5, Zn 2 - 4, Pb 6 - 8 | 8.8 | 130 | 270 | 13 | 106,000 | 75 | |||

| 2.1090.04 | CuSn7ZnPb | B 505 | Cu 81 - 85, Sn 6.3 - 7.5, Zn 2 - 4, Pb 6 - 8 | 8.8 | 120 | 270 | 16 | 106,000 | 70 | |||

| 2 | 1705 | 2.1061.01 | CuSn12Pb | Not yet standardized | Cu 84 - 87, Sn 11 - 13, Pb 1 - 2 | 8.7 | 140 | 260 | 10 | 112,000 | 80 | Commonly used in manufacturing bearings, bushings, and components that require high load capacity and wear resistance, especially in marine and industrial applications. |

| 2.1061.03 | CuSn12Pb | Not yet standardized | Cu 85 - 88, Sn 10 - 12, Pb 1 - 1.5 | 8.7 | 150 | 280 | 5 | 112,000 | 90 | |||

| 2.1061.04 | CuSn12Pb | B 505 | Cu 85 - 88, Sn 10 - 12, Pb 1 - 1.5 | 8.7 | 140 | 280 | 7 | 112,000 | 85 | |||

| 3 | 1714 | 2.0975.01 | CuAl10Ni | B 584 | Cu min. 75, Al 8.5 - 11.0, Ni 4.0 - 6.5, Fe 3.5 - 5.5 | 7.6 | 270 | 600 | 12 | 122,000 | 140 | Used in marine, aerospace, and heavy machinery for manufacturing bearings and components requiring high strength and durability. Known for extreme loads and high corrosive environments. |

| 2.0975.02 | CuAl10Ni | B 30 | Cu min. 75, Al 8.5 - 11.0, Ni 4.0 - 6.5, Fe 3.5 - 5.5 | 7.6 | 300 | 600 | 14 | 122,000 | 150 | |||

| 2.0975.03 | CuAl10Ni | B 271 | Cu min. 75, Al 8.5 - 11.0, Ni 4.0 - 6.5, Fe 3.5 - 5.5 | 7.6 | 300 | 700 | 13 | 122,000 | 160 | |||

| 2.0975.04 | CuAl10Ni | B 505 | Cu min. 75, Al 8.5 - 11.0, Ni 4.0 - 6.5, Fe 3.5 - 5.5 | 7.6 | 300 | 700 | 13 | 122,000 | 160 | |||

| 4 | 1709 | 2.0598.01 | CuZn25Al5 | B 584 | Cu 60 - 67, Al 3 - 7, Fe 1.5 - 4, Mn 2.5 - 5, Zn rest | 8.2 | 450 | 750 | 8 | 115,000 | 180 | Used in heavy-duty bearings, hydraulic components, and marine hardware. Designed for high loads and resistance to corrosive attack. |

| 2.0598.02 | CuZn25Al5 | B 30 | Cu 60 - 66, Al 5 - 7.5, Fe 2 - 4, Mn 2.5 - 5, Zn 22 - 28 | 8.2 | 480 | 750 | 8 | 115,000 | 180 | |||

| 2.0598.03 | CuZn25Al5 | B 271 | Cu 60 - 66, Al 5 - 7.5, Fe 2 - 4, Mn 2.5 - 5, Zn 22 - 28 | 8.2 | 480 | 750 | 5 | 115,000 | 190 | |||

| 5 | 1705 | 2.1052.01 | CuSn12 | Not yet standardized | Cu 84 - 88, Sn 11 - 13, Pb 1, Ni 2.0, Sb 0.2, P 0.2 | 8.6 | 140 | 260 | 12 | 110,000 | 80 | Commonly used in manufacturing bearings, gears, and components requiring high wear resistance. Known for good machinability and corrosion resistance, particularly in seawater environments. All rights to the listed content are reserved by https://www.viiplus.com/ |

| 2.1052.03 | CuSn12 | Not yet standardized | Cu 85 - 88, Sn 10 - 12, Pb 1 - 1.5 | 8.6 | 150 | 280 | 8 | 110,000 | 90 | |||

| 2.1052.04 | CuSn12 | Not yet standardized | Cu 85 - 88, Sn 10 - 12, Pb 1 - 1.5 | 8.7 | 140 | 280 | 8 | 110,000 | 95 | |||

| Note: Delivery form codes: .01 = sand casting, .02 = gravity casting, .03 = centrifugal casting, .04 = continuous casting. | ||||||||||||

♦ Width and length of wearstrip determines hole

pattern, regardless of thickness.

♦ Self-lubricating wear plates are manufactured from bronze or steel with graphite plugs. The plugs cover 20-25% of the wear surface.

♦ Wear plates are also available in plain steel.

In addition to “made to order” specials, a wide range of catalog

components can be modified to

meet customer specific applications. Round, flat, simple or

complex, we want to make those

one-of-a-kind parts for you.

VIIPLUS is a SUPPLIER of tool, die and mold components for the metal-working and

plastics industries. Asa customer-focused, world-class supplier of

choice, we provide

the brands, product breadth, distribution network and technical

support for all your metal forming needs.Our goal is to give our

customers the most innovative and valueadded

products and services.

|