| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Bottle Inspection Vision System |

|---|---|

| Brand Name: | KEYE |

| Model Number: | KY-PE-C10 |

| Place of Origin: | china |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | T/T,L/C |

| Supply Ability: | 1 set per 4 weeks |

| Delivery Time: | 6 to 8 weeks |

| Packaging Details: | Fumigation-free wood |

| Certification: | ISO/CE |

| Application: | Bottle Inspection |

| Inspection Process: | Real-Time Inspection |

| Inspection Environment: | Industrial Environment |

| Technology: | Vision System |

| Inspection Software: | Customizable Software |

| Inspection Lighting: | LED Lighting |

| Inspection Objects: | Bottles |

| Inspection System: | Automated System |

| Inspection Resolution: | High Resolution |

| Inspection Camera: | High Resolution Camera |

| Inspection Accuracy: | High Accuracy |

| Inspection Speed: | High Speed |

| Inspection Interface: | User-Friendly Interface |

| Inspection Type: | Defect Detection |

| Company Info. |

| Anhui Keye Intelligent Technology Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

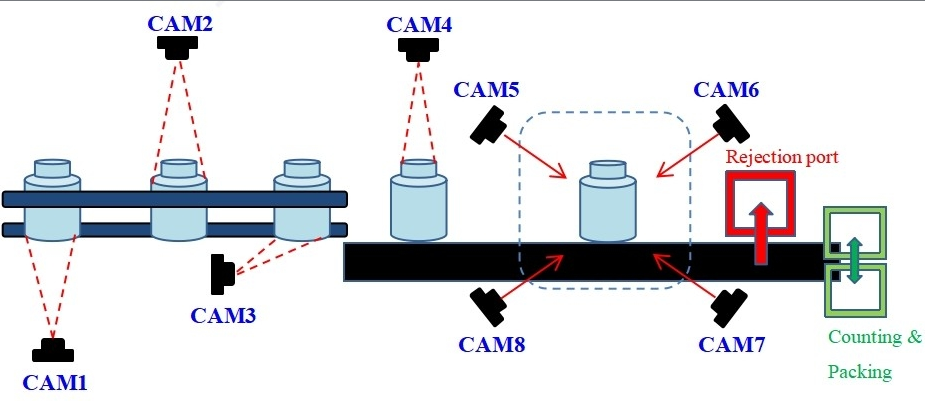

New Upgrade 10 Cameras Defective Bottle Inspection Machine with Energy-Efficient System

The defective bottle inspection machine generates comprehensive defect output software packages, providing visibility into quality issues for informed decision-making. Ensure the highest quality standards with our bottle quality inspection machine. Elevate your quality control with our defective bottle inspection machine, expertly designed for plastic caps. Featuring a proprietary high-definition camera (“HD Eye”) and advanced optical imaging, this machine captures clear images for precise defect detection. Powered by our robust AI cloud platform (“Super Brain”), it processes, analyzes, and labels images swiftly, establishing accurate defect models.

The quality testing machine can perform full area comprehensive

inspection on the appearance defects of products, including

conventional defects black spot, crack, thread, flash, short shot,

deformation, etc.

|