| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | X Ray Machine |

|---|---|

| Brand Name: | Honreal |

| Model Number: | DS-3000 |

| Certification: | CE |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | Negotiable |

| Payment Terms: | T/T,, Western Union, MoneyGram |

| Supply Ability: | 100 Sets Per Month |

| Delivery Time: | 20 work days |

| Packaging Details: | Export wooden box packaging |

| Product name: | X-Ray Reel Component Counting Machine |

| Accuracy: | 99.99% (0201) |

| Resolution: | 3072*3072px |

| Max inspection speed: | 7" ~ 17" |

| Pixel size: | 139μm |

| Dimension: | 950*1460*1960mm |

| Company Info. |

| Shenzhen Honreal Technology Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Working principle

The system of this series of equipment is primarily composed of seven main components: X-ray source, image imaging unit, computer image processing system, mechanical system, electrical control system, safety protection system, and warning system. It integrates modern non-destructive testing, computer software technology, image acquisition and processing technology, mechanical transmission technology, and AI algorithms. It covers the four major technical fields of optics, mechanics, electronics, and algorithms. By exploiting the differences in X-ray absorption caused by different materials or thicknesses, the internal components of electronic device trays are imaged and counted for detection.

The X-RAY intelligent component counting machine is designed to work in conjunction with SMT production lines for automatic counting of residual materials. This machine can simultaneously count four material reels, automatically scan codes, and achieve the goal of reducing labor and increasing efficiency. The X-RAY intelligent component counting machine can be integrated with MES systems as needed, making residual material counting and material warehousing more efficient, secure, and data-oriented.

Specifications:

| General Specification | |

| Working mode | Off-line |

| Dimensions(mm) | 800(W)X1380(D)X1950(H) |

| Weight | Approx. 800 KG |

| Power supply | 110~220VAC 50/60Hz, 1.5KW |

| System Computer | |

| Industrial PC | Industrial PC with Intel i7 processor (64bit) |

| Operating System | Window 10 OS |

| Display | 27" FHD LCD Display |

| Storage System | |

| RAM:16GB, HDD:1TB + SSD:256G | |

| Accessories Included | |

| Handheld Barcode scanner | / |

| Label printer | / |

| Inspection Capabilities | |

| Tape & reel size | 7" ~ 17" |

| Scan height | ≤80mm |

| Max inspection speed | 7”~17” |

| Tape & Reel | <10s/Reel or 4*7” reel<10s. |

| Min component size | 01005 |

| Inspection accuracy | ≥99.99% |

| X-Ray Tube | |

| Type | Closed tube |

| Max Voltage | 50KV |

| Max. Current | 1000 μA |

| Focus spot size | 0.03mm |

| Imaging System | |

| Type | Flat Panel Detector (FPD) |

| Effective detection range: | 430mmx430mm |

| Pixel matrix | 3072*3072 pixel |

| Pixel size | 139μm |

| Frame Rate | 6fpsv |

| AD Conversion | 16 bits |

| Detectable Package | |

| Chip, Bulks, ESD packages, JEDEC Tray, Tube, Transistor. | |

| Detectable Components | |

Capacitors, resistors, inductors, beads, crystals, transistors, diodes, FETs, various types of resistors, bile capacitors, detectable connectors, integrated circuit chips, etc | |

| Database | |

| Support connection with MES, ERP, and WMS Intelligent | |

| Safety System | |

| Standard | Conformed to FDA-CDRH regulation CFR 21 1020.40 subchapter for cabinet x-ray systems. |

| X-ray emission | ﹤ 1μSv/h (FDA-CDRH regulation CFR 21 1020.40 subchapter standard required < 5μSv/h) |

| Authority management | Fingerprint and password assessing system. |

| Shielded cabinet protection against radiation leakage | |

| Real time radiation leakage monitoring meter | |

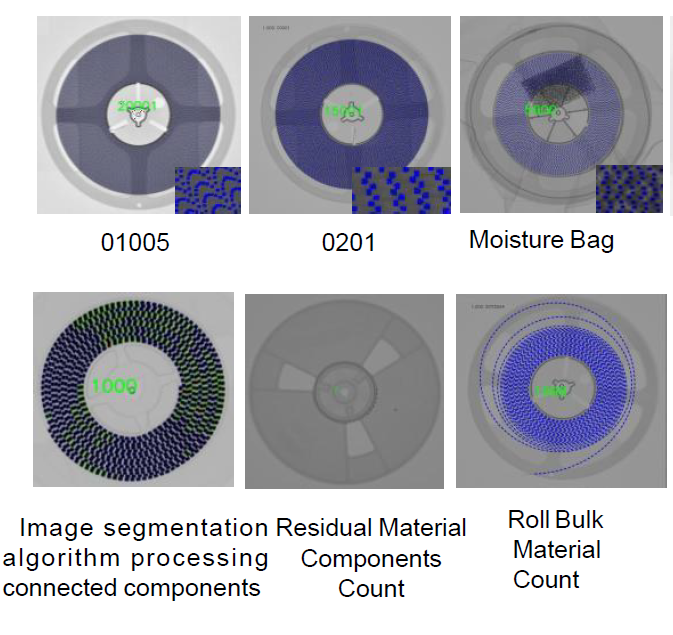

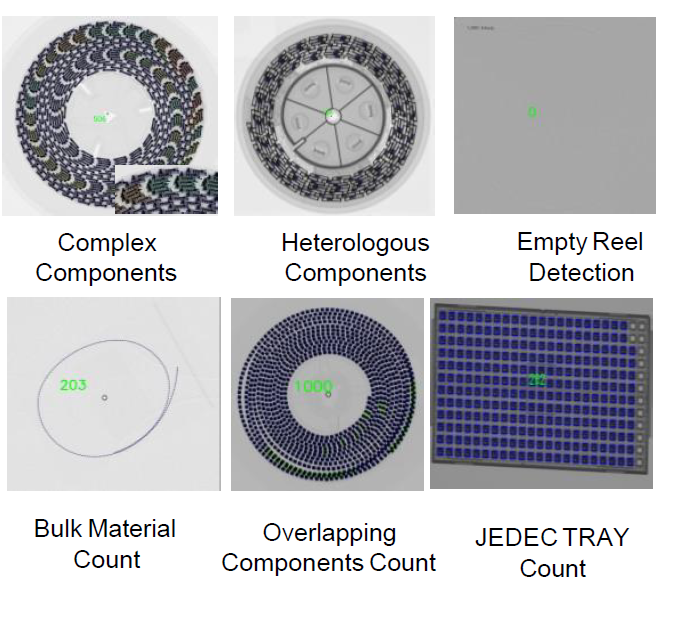

Component Counting System

Apply the AI-optimized counting algorithm to realize spot

inspection of various materials: standard SMD, dicing tape,

JEDEC/Matrix tray, MELF, Aluminum Caps, Soic, To, BGA/CPU, Tantal,

filter and other parts. Four material pallets can be counted at the

same time, and it only takes 8 seconds to complete, which shortens

the counting time of parts pallets, automatically uploads data to

the cloud, regularly updates the database, and links with the

factory ERP/MES system, greatly saving time and cost. Easy to

manage.

|