| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Belt Filter Press Machine |

|---|---|

| Brand Name: | TONTEN |

| Model Number: | TT-1000 |

| Place of Origin: | China |

| MOQ: | 1 Set |

| Payment Terms: | T/T |

| Supply Ability: | 30 Sets per month |

| Delivery Time: | 7-10work days |

| Packaging Details: | Export wooden packing or load in container |

| Product name: | Belt Filter Press Machine |

| Host power: | 3kw |

| Filter belt width: | 1000-3500mm |

| Filtration area: | 30-105m2 |

| Capacity: | 2-20m3/h |

| Weight: | 6500kg |

| Application: | Urban domestic sewage |

| Advantage: | Environmental friendly |

| Company Info. |

| TONTEN MACHINERY LIMITED |

| Verified Supplier |

| View Contact Details |

| Product List |

Belt Filter Printing Dyeing Sludge Water Treatment Belt Filter Press Machine

Product Description:

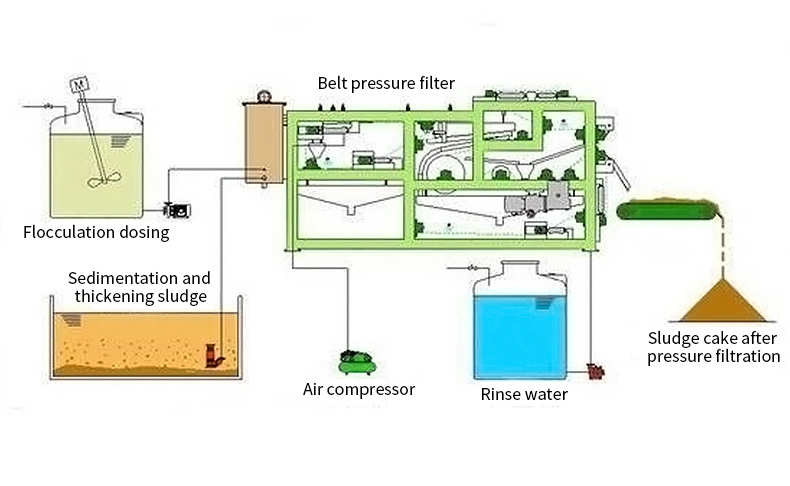

Belt filter press The dehydration process of belt filter press can

be divided into four important stages: pretreatment, gravity

dehydration, wedge zone pre-pressure dehydration and pressure

dehydration. The technology uses new equipment filter presses, such

as program-controlled automatic chamber filter presses, diaphragm

filter presses, deep sludge dehydration filter presses, integrated

sewage sludge treatment equipment, and online precision filtration

systems. Reasonably priced, reliable and environmentally friendly

filtration products.

The independent concentration section can easily filter the coagulated sludge, greatly improving the processing capacity. Simple structure, simple operation and easy maintenance. Special concave and convex roller design, large processing capacity and low water content. Superior patented filter belt, fast filtrate separation, excellent mud cake peeling, less sludge residue. Good sludge capture rate and high efficiency. High stability and excellent durability. No noise and vibration. Low power consumption. The filter cloth is non-sticky to sludge, and the equipment requires less cleaning water.

Specification:

| Model | TT-1000 | TT -1500 | TT -2000 | TT -2500 | TT -3000 | TT -3500 | |

| Power (KW) | Host | 3 | 4 | 5.5 | 7.5 | 11 | 11 |

| Complete set | 16 | 18.5 | 30 | 32 | 35 | 35 | |

| Filter belt width(mm) | 1000 | 1500 | 2000 | 2500 | 3000 | 3500 | |

| Filtration area(m2) | 30 | 45 | 60 | 75 | 90 | 105 | |

| Capacity(m3/hr) | 2-4 | 4-6 | 6-9 | 9-12 | 12-15 | 15-20 | |

Dimensions | Length(mm) | 5200 | 5400 | 5500 | 5600 | 5600 | 5600 |

| Width(mm) | 1650 | 1900 | 2380 | 2900 | 3400 | 3900 | |

| High(mm) | 1950 | 2100 | 2150 | 2200 | 2300 | 2350 | |

| Model weight(kg) | 3200 | 4200 | 6500 | 9000 | 12000 | 15000 | |

Working principle and workflow:

After the concentrated sludge is fully mixed with a certain

concentration of flocculant in a static and dynamic mixer, the tiny

solid particles in the sludge are aggregated into larger floccules,

and free water is separated at the same time. The flocculated

sludge is transported to the filter belt for concentrated gravity

dehydration. Under the action of gravity, the free water is

separated to form stagnant sludge, which is then clamped between

the upper and lower mesh belts. Under the action of the squeezing

force and shear force from small to large in the wedge-shaped

pre-pressing area, low pressure area and high pressure area, the

sludge is gradually squeezed to achieve the maximum separation of

mud and water, and finally forms a filter cake for discharge.

1. Chemical pretreatment dehydration

In order to improve the dehydration of sludge, improve the

properties of filter cakes, and increase the permeability of

materials, the sludge needs to be chemically treated. The belt

filter press uses the "water flocculation granulation mixer" device

to achieve the effect of chemical dosing flocculation. This method

not only has a good flocculation effect, but also saves a lot of

reagents and has low operating costs.

2. Gravity concentration and dehydration section

The sludge is evenly fed into the mesh belt through the cloth

hopper. The sludge moves forward with the filter belt. The free

water flows into the water receiving tank through the filter belt

under the action of its own weight. Gravity dehydration can also be

said to be a highly concentrated section. Its main function is to

remove free water from the sludge, reduce the fluidity of the

sludge, and prepare for further extrusion.

3. Wedge-shaped zone pre-pressure dehydration section

The fluidity of the sludge after gravity dehydration is almost

completely lost. As the filter belt of the belt filter press moves

forward, the distance between the upper and lower filter belts

gradually decreases, and the material begins to be slightly

pressed. As the filter belt runs, the pressure gradually increases.

The role of the wedge-shaped area is to extend the gravity

dehydration time, increase the extrusion stability of the flocs,

and prepare for entering the pressure zone.

4. Squeeze roller high-pressure dehydration section

When the material leaves the wedge-shaped area, it enters the

pressure area. The material is squeezed in this area. The pressure

along the running direction of the filter belt increases with the

decrease of the squeezing roller diameter. The material shrinks in

volume due to squeezing, and the interstitial free water in the

material is squeezed out. At this time, the filter cake is

basically formed. Continue forward to the high-pressure area at the

tail of the pressure, and the water content of the filter cake can

be reduced to the minimum after high pressure.

Features:

The belt filter press has a compact structure, novel style,

convenient operation and management, large processing capacity, low

filter cake moisture content and good effect.

1. The first gravity dewatering section is inclined, which

increases the height of the sludge in the gravity dewatering

section and improves the gravity dewatering capacity.

2. The gravity dewatering section is long, with a total length of

more than 5m for the first and second gravity dewatering sections,

so that the sludge is fully dehydrated and loses fluidity before

pressing. At the same time, the gravity dewatering section is also

equipped with special mechanisms such as reversal, and the sludge

filter cake obtains the lowest moisture content through "wedge" and

"S" shaped pressing.

3. The first dewatering roller adopts a "T" type drain trough to

quickly discharge a large amount of water after pressing, thereby

improving the dewatering effect.

4. The filter belt deviation is equipped with an automatic control

device, and the filter belt tension and filter belt moving speed

can be freely adjusted, which is convenient for operation and

management.

5. Low noise and no vibration.

6. Small amount of chemical drugs

Applications:

Belt filter press is suitable for sludge dehydration in wastewater

treatment processes in urban sewage treatment plants,

pharmaceuticals, electroplating, papermaking, leather, printing and

dyeing, metallurgy, chemicals, slaughtering, food, brewing, coal

washing and environmental protection projects. It can also be used

for solid-liquid separation in industrial production. It is an

ideal equipment for environmental governance and resource recovery.

FAQ:

1.How can I get the price?

-We usually quote within 15 minutes after we get your inquiry

2. Is this machine easy to install?

Will you arrange engineer to help me install?

-This machine is very easy for install. The machine you received

is assembled. You will only need to follow steps on our English

instruction and video.

3.How do you make our business long-term and good relationship?

-1. We keep good quality and competitive price to ensure our

customers benefit

-2. We respect every customer as our friend and we sincerely do

business

and make friends with them,no matter where they come from.

|