| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Graphite Petroleum Coke |

|---|---|

| Brand Name: | Hensen |

| Place of Origin: | Inner Mongolia |

| MOQ: | 20 TONS |

| Price: | USD$300/TON-USD$3000/TON |

| Payment Terms: | T/T |

| Supply Ability: | 3000 ton per month |

| Delivery Time: | 30 working days |

| Packaging Details: | Jumbo bag |

| Model Number: | HS |

| Certification: | Certificate of Origin |

| Product Name: | Graphite Petroleum Coke |

| Application: | Carbon Riser |

| Feature: | high fixed carbon content |

| Moisture(Max): | 0.5% |

| Ash: | 0.5% 0.7% 1% 2% |

| N Max: | 100pm 200ppm 300ppm 500ppm |

| Company Info. |

| Qingdao Hensen Graphite Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Carbon Raiser Foundry Coke GPC Graphite Petro Coke

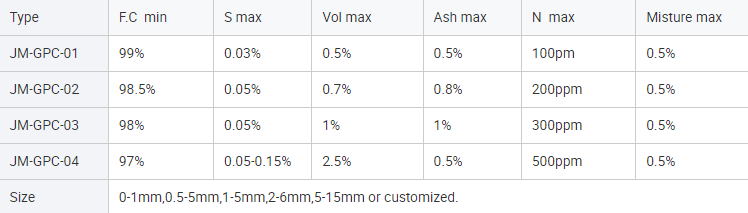

Graphitized Petroleum Coke is made from high quality green petroleum coke,which is under the high temperature process at 2800℃,GPC has the characteristics of high fixed carbon content,low sulfur content,low nitrogen content,high absorb rate.It’s widely used for high quality steel products, special steel products and the relevant metallurgy & foundry industries. Also,it can be used as additives for plastic&rubber products.

| F.C | Sulphur(Max) | Volatile Matter | Ash(Max) | N Max | Moisture(Max) |

| 99 | 0.03 | 0.5 | 0.5 | 100pm | 0.5 |

| 98.5 | 0.05 | 0.7 | 0.7 | 200ppm | 0.5 |

| 98 | 0.05 | 0.7 | 1 | 300ppm | 0.5 |

| 97 | 0.05-0.15 | 0.7 | 2 | 500ppm | 0.5 |

Q: Where is your factory located? How can I visit there?

A: Our factory is located in Shandong Province,China which has rich coal.All our clients, from home or

abroad, are warmly welcome to visit us.

Q: How can I get the sample?

A: We’d like to supply samples free of charge, but you need pay for the freight fees.

Q: How does your factory do regarding quality control?

A: Quality is priority. My company always attaches great importance to quality controlling from the very beginning to the very end.

Q: How can I pay you?

A: After you confirm our PI, we will request you to pay. T/T is the most usual ways we are using.

Q: How do you check all the goods in the production line?

A: We have spot inspection and finished product inspection. We

check the goods when they go into next step production procedure.

|