| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | CTP Plate Machine |

|---|---|

| Brand Name: | EcooGraphix |

| Model Number: | ECOO FP-900 |

| Certification: | ISO9000, CE |

| Place of Origin: | China |

| MOQ: | 1 SET |

| Price: | Negotiable |

| Payment Terms: | T/T |

| Supply Ability: | 1000 Sets/Year |

| Delivery Time: | 30 DAYS |

| Packaging Details: | Standard Export Packing |

| Working Power: | 3.5KW |

| Type: | Solvent based flexo plate making machine |

| Page Size: | Max. 920mm*680mm |

| Plate Thickness: | 1.14mm - 3.94mm |

| Electricity Requirement: | Single phase 220V 50/60Hz |

| Machine Size (WxLxH)mm: | 1100x1280x870 |

| Classification: | CTP Plate Processor |

| Net Weight: | 190kg |

| Power Supply: | single phase:220V, 50/60 Hz, power Consumption:6.5KW |

| Company Info. |

| Hangzhou Ecoographix Digital Technology Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

FP-900 Solvent Based Flexo CTP Plate Processor

Application

Regardless of the PS plate or the CTP plate, a processing machine is required for processing the plate after the exposure is completed. EcooGraphix CTP Processor can be used with Offline/ Online Thermal CTP or CTCP or UV-CTP platesetters, such as Kodak, Screen, Agfa, Creo, Amsky or Cron CTP machines.

Machine Features

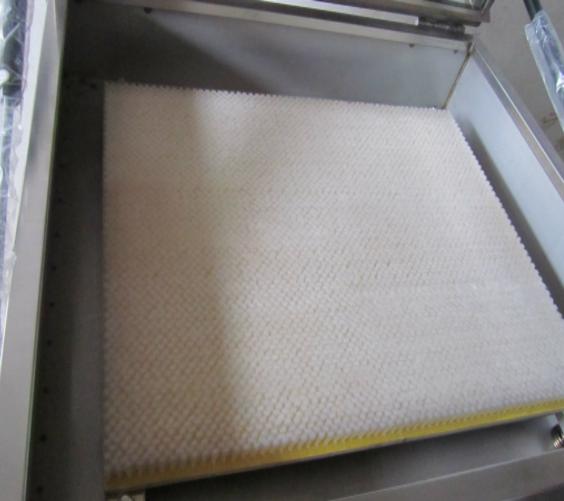

1. Multi-functional solvent-base flexo plate making machine, allows for exposure, wash-out, drying and de-tacking.

2. AIO design, save space, suitable for small format Flexo CTP Machine.

3. MPU central control panel makes operation easy.

4. Adopt imported UV lamps and electronic ballast.

5. Strong vacuum device and sucking air plate.

6. Circle thermostatic air drying device assures.

7. Accurate and stable re-productivity of the original colors and graphics.

Specification

Model

FP-900

Page Size

Max. 920mm*680mm

Plate Thickness

1.14mm - 3.94mm

Electricity Requirement

Single phase 220V 50/60Hz

Working Power

3.5KW

Machine Size (WxLxH)mm

1650x1160x1300

| Flexo Plate Processing AIO Machine(AIO, All in one model) | |

| Model | FP-900 |

| Page Size | Max. 920mm*680mm |

| Plate Thickness | 1.14mm - 3.94mm |

| Electricity Requirement | Single phase 220V 50/60Hz |

| Working Power | 3.5KW |

Machine Size (WxLxH)mm | 1650x1160x1300 |

Caution And Process

The progress of working:

Producing And Packaging

From producing to delivery, we make every details very carefully to guarantee the good product quality and service to customers.

Installation Cases

Certificates

FAQ

Q1: What are your main products ?

A: Our main products are the Prepress 4up and 8up Online/Offline

Thermal CTP, CTCP, VLF CTP, Flexo CTP, Processor, Offset Plates,

Offset Inks, Offset Printing Blankets, Postpress Packing Equipment

and so on.

You can get the equipment and consumables all in one and no worry about the after-sales service from our company.

Q2: Where is your factory ?

A: Our CTP Processor machine factory is in Shanghai, you are warmly

welcome to visit our factory!

Q3: Is there any certification for your CTP Processor ?

A: Yes, all our machines have been certified by SGS and CE.

Q4: Can you also supply the Workflow and RIP ?

A: Yes, we can provide the Workflow Brainnew and RIP Compose V12.

Q5: What about the installation and after-sales technician support

?

A: Our engineer can go to help the installation and provide the

necessary training. The buyer should take the round air plane

tickets, service charge and the local accommodation cost. Any

problems or questions, we will be at your disposal 7x24 hours. Among our large amount of CTP installations worldwide, there are

also many end users(printers) who have purchased the CTP products

from EcooGraphix China directly and EcooGraphix technical service

team support these installations remotely with regular onsite

visits.

These end users printers all run the CTP systems with full satisfaction due to our robust quality, seamless remote service, thorough training and maintanence. If you are a printer who is considering purchasing directly from EcooGraphix China, there is no hassle on installations, training and after sales service. We guarantee your satisfaction.

|