| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Rubber Vulcanizing Press Machine |

|---|---|

| Brand Name: | Beishun |

| Model Number: | XPLW-1500×1500 |

| Certification: | ISO/CE/SGS |

| Place of Origin: | Qingdao,China |

| MOQ: | 1set |

| Price: | Negotiable |

| Payment Terms: | T/T,L/C |

| Supply Ability: | 30sets/month |

| Delivery Time: | 40day |

| Packaging Details: | Wooden box/container |

| Control Type: | Automatic |

| Clamping Pressure: | 800T/custom made |

| Plate Size: | 1500x1500mm or as your requirements |

| Heating System: | Electric Heating |

| Hs Code: | 84778000 |

| Warranty: | 1 year |

| Customized: | Yes |

| Plunger Material: | Chilled cast iron |

| Driving Motor: | 3kw |

| Hydraulic Unit: | Rexroth, Huade, Yuken, Seven Ocean |

| Column: | Polishing Treatment |

| Auto: | Automatic |

| Operation Mode: | Manual/Automatic |

| Character: | With push-pull mould |

| Company Info. |

| Qingdao Beishun Environmental Protection Technology Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

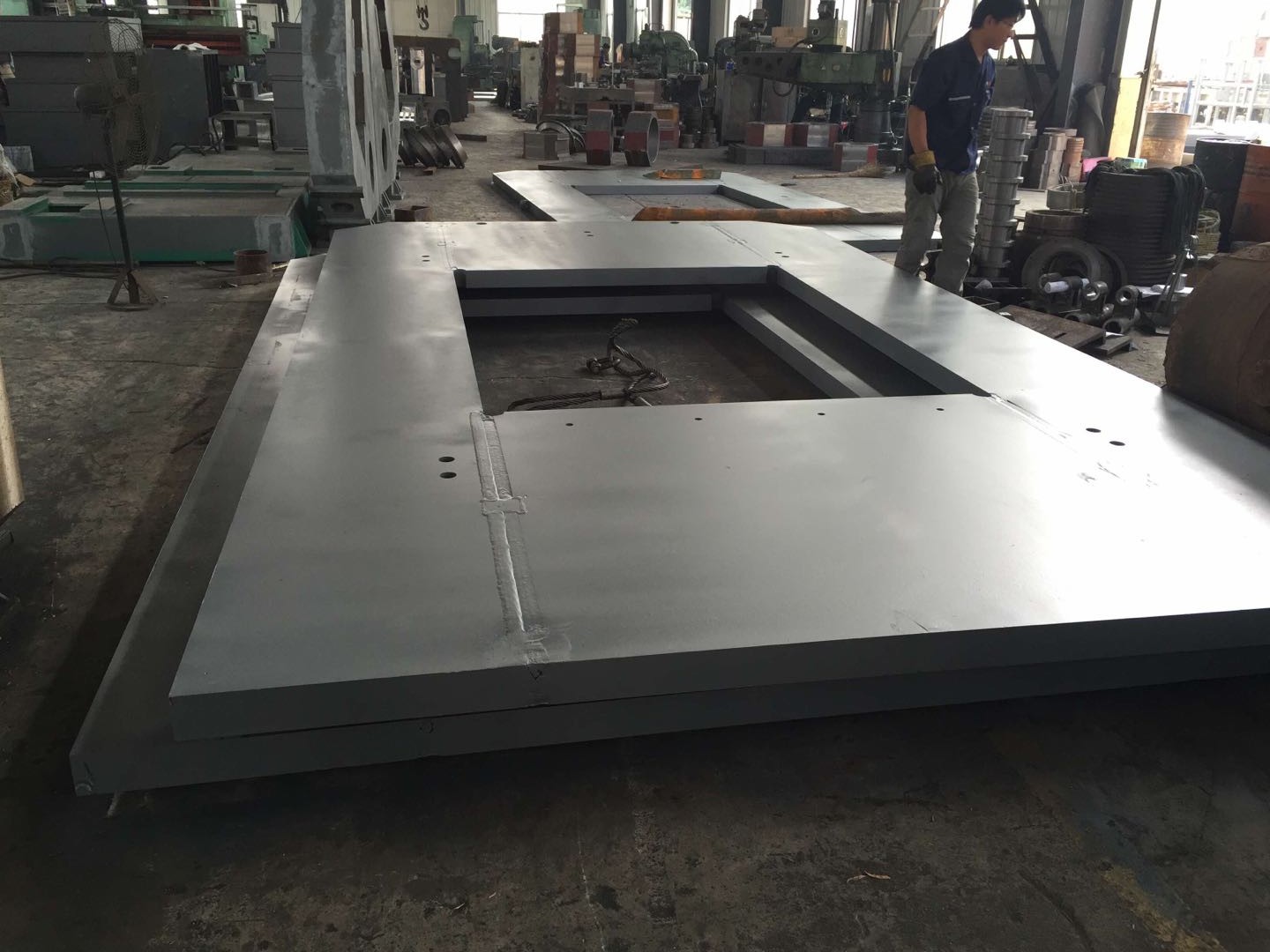

Large One-Layer Rubber Molding Press Uses 1500×150mm Hot Plate And

800 Tons Of Pressure

Rubber Molding Press introduction

1500×1500mm hot plate rubber vulcanizer is a large rubber

processing equipment. The following is its relevant information:

1. Main technical parameters:

- Nominal clamping force: usually 6300KN and above. The strong

clamping force can ensure that the rubber maintains a good molding

state during the vulcanization process.

- Hot plate spacing: generally around 125-300mm, which can be

adjusted according to the specific rubber product processing

requirements. The larger spacing adjustment range can adapt to the

processing of rubber products of different thicknesses.

- Hot plate unit area pressure: about 2.8MPa, uniform pressure

distribution is crucial for the vulcanization quality of rubber

products.

- Heating method: There are two common types of heating: electric

heating and steam heating. Electric heating has the advantages of

fast heating speed and precise temperature control; steam heating

is relatively energy-saving, but it needs to be equipped with

additional equipment such as steam generators.

- Motor power: generally 13KW and above, providing sufficient power

for the operation of the vulcanizer.

2. Scope of application:

- Due to the large size of the hot plate, it is suitable for the

production of large rubber products, such as large rubber pads,

rubber tracks, large rubber seals, etc.

- For some rubber products with high requirements for vulcanization

process and strict requirements for product size accuracy, the

1500×1500mm hot plate rubber vulcanizer can also meet the

production needs well.

3. Advantages:

- High production efficiency: The large hot plate can process

multiple rubber products or large rubber products at a time, which

greatly improves production efficiency.

- Good vulcanization quality: Accurate temperature control, uniform

pressure distribution and stable operating performance ensure the

vulcanization quality of rubber products, giving them good physical

properties and dimensional accuracy.

- Easy operation: Modern 1500×1500mm hot plate rubber vulcanizers

are usually equipped with an automated control system, which is

simple and convenient to operate, and can realize functions such as

one-button start and automatic vulcanization.

4. Market price: Depending on different configurations, brands and

functional requirements, the price of 1500×1500mm hot plate rubber

vulcanizers varies greatly, and we need to customize the machine

according to your requirements

Technical Parameters:

| Type | XLB-DQ1200× 1200× 2 | XLB-DQ1300× 2000× 1 | XLB-Q1200× 2500× 1 | XLB-Q1500× 2000× 1 | XLB-Qhe2000× 3000× 1 | XLB-Q1400× 5700× 1 |

| Total pressure(MN) | 315t | 560t | 750t | 1000t | 1800t | 2800t |

| Platen size(mm) | 1200× 1200 | 1300× 2000 | 1200× 2500 | 1500× 2500 | 2000× 3000 | 1400× 5700 |

| Daylight (mm) | 200 | 400 | 400 | 400 | 400 | 400 |

| No of Daylights | 2 | 1 | 1 | 1 | 1 | 1 |

| Piston stroke(mm) | 400 | 400 | 400 | 400 | 400 | 400 |

| Plate Unit Area pressure(Kg/cm2) | 22 | 21.5 | 25 | 33.5 | 30 | 35 |

| Main motor power(KW) | 3 | 8 | 9.5 | 11 | 26 | 43.5 |

| Overall dimension(L× W× H) (mm) | 1685× 1320× 2450 | 2000× 1860× 2500 | 2560× 1700× 2780 | 2810× 1550× 3325 | 2900× 3200× 2860 | 2400× 5800× 3600 |

| Weight(kg) | 9500 | 17000 | 20000 | 24000 | 66000 | 110000 |

|