| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Railway Track Parts |

|---|---|

| Brand Name: | HTR |

| Place of Origin: | CHINA |

| MOQ: | 1000 |

| Price: | Ngotiable |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50000 pcs per month |

| Delivery Time: | Ngotiable |

| Packaging Details: | Export packaging |

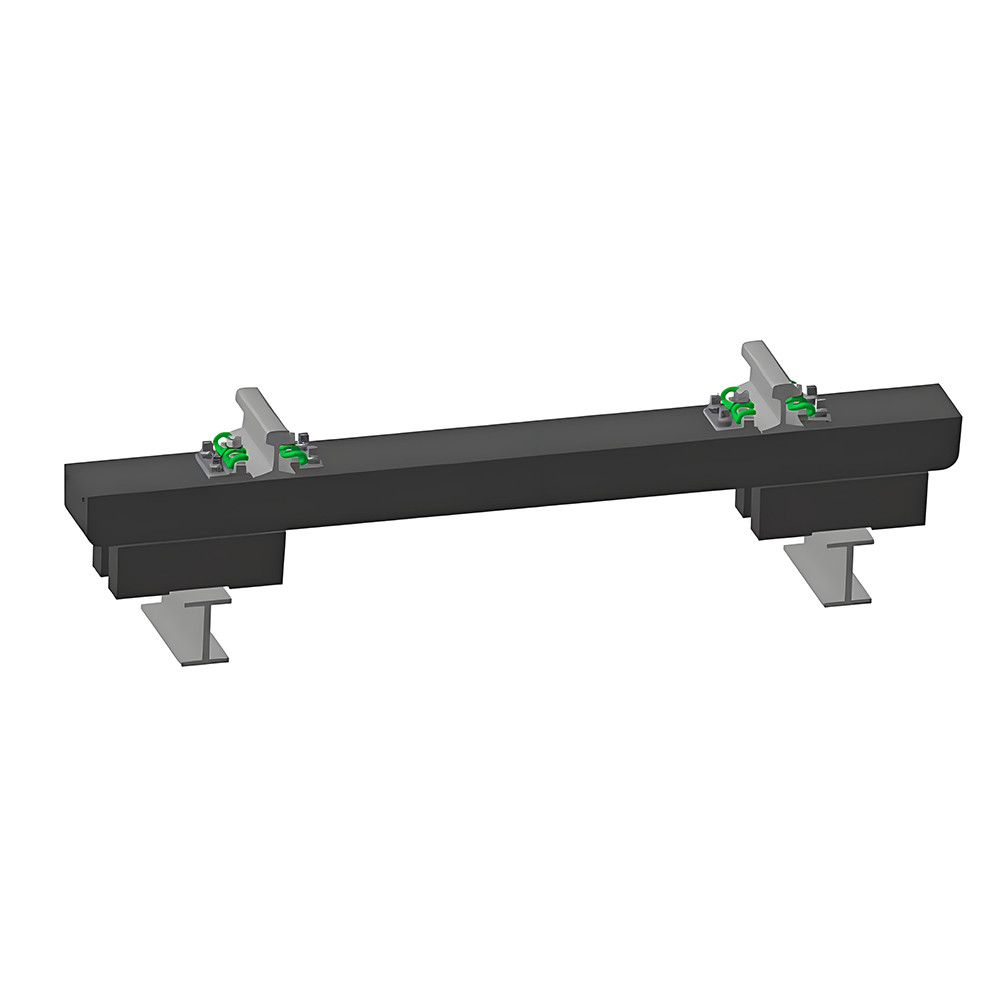

| Product name: | Composite Sleepers |

| Material: | Composite |

| Electrical resistance: | > 150 kΩ |

| Density: | ~ 1.55 g/cm3 |

| Fire behaviour: | Difficult to ignite, low smoke development |

| Modulus of elasticity: | 2.300 - 7.300 MPa |

| Company Info. |

| Chongqing Hengtairail Equipment Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

| Fields of application | Direct fastening | Indirect fastening | Turnout sleepers | Bridge beams |

| Axle loads | up to 35.5 t | up to 35.5 t | up to 25 t | up to 25 t |

| Electrical resistance | > 150 kΩ | > 150 kΩ | > 150 kΩ | > 150 kΩ |

| Density | ~ 1.55 g/cm3 | ~ 1.55 g/cm3 | ~ 1.55 g/cm3 | ~ 1.55 g/cm3 |

| Coefficient of thermal expansion | 19,8 x 10-6 1/K | 17,5 x 10-6 1/K | 17,5 x 10-6 1/K | 23,9 x 10-6 1/K |

| Modulus of elasticity | 2.300-7.300 MPa | 2.300-7.300 MPa | 2.300-7.300 MPa | up to 8.500 MPa |

| Anchoring pull-out forces for standard sleeper screws | > 85 kN | > 70 kN (drilled screw hole) | > 70 kN (drilled screw hole) | > 70 kN (drilled screw hole) |

| > 85 kN | ||||

| > 85 kN (prefabricated screw hole) | (prefabricated screw hole) | |||

| Water absorption | ~ 0.1% | ~ 0.1% | ~ 0.1% | ~ 0.1% |

| Fire behaviour | Difficult to ignite, low smoke development | |||

| Dimensions[mm] | 160 x 260 x 2.600 150 x 250 x 2.600 | 160 x 260 x 2.600 150 x 250 x 2.600 | 160 x 260 x 2.200-5.000 150 x 250 x 2.200-5.000 | Basic bridge beam 160 x 240 x 2,600 Height adjustment elements up to 160 mm Total height from 160 up to 320 |

| Weight | 170 kg | 175 kg | 74 kg/m | 170 - 200 kg |

Develop a composite sleeper that combines the best properties of wooden, concrete, Environmental considerations are also playing an increasingly important role in the development of railway sleepers. Our responsibility as a leading developer of railway infrastructure components must therefore be to extend the range of products we offer by an especially eco-friendly and resource-saving alternative to traditional solutions. and plastic sleepers.To use polymer, filler sand and additives to create a completely new and innovative material that can withstand even the most

|