| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Canned Food Packaging Machine |

|---|---|

| Brand Name: | Peiyu |

| Model Number: | customized |

| Certification: | CE,ISO9001:2008,High-tech enterprise |

| Place of Origin: | China |

| MOQ: | 1 |

| Price: | Individual quotation according to different requirements |

| Payment Terms: | T/T,L/C |

| Supply Ability: | 30 pcs per month |

| Delivery Time: | 10-20 workdays |

| Packaging Details: | The packaging uses new, sturdy special packaging boxes or fixed frames, which are suitable for long-distance transportation, moisture-proof, rust-proof, shock-proof, and suitable for land and sea transportation and overall lifting. |

| Name: | Loading and unloading cage system |

| Machine speed: | 3 layers/min |

| Installed power: | 15Kw |

| Air pressure: | 7bar |

| Air consumption: | 1000L/min |

| hydraulic lifting systems: | All hydraulic lifting systems are well-known brands |

| Company Info. |

| Shanghai Peiyu Packaging Technology Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

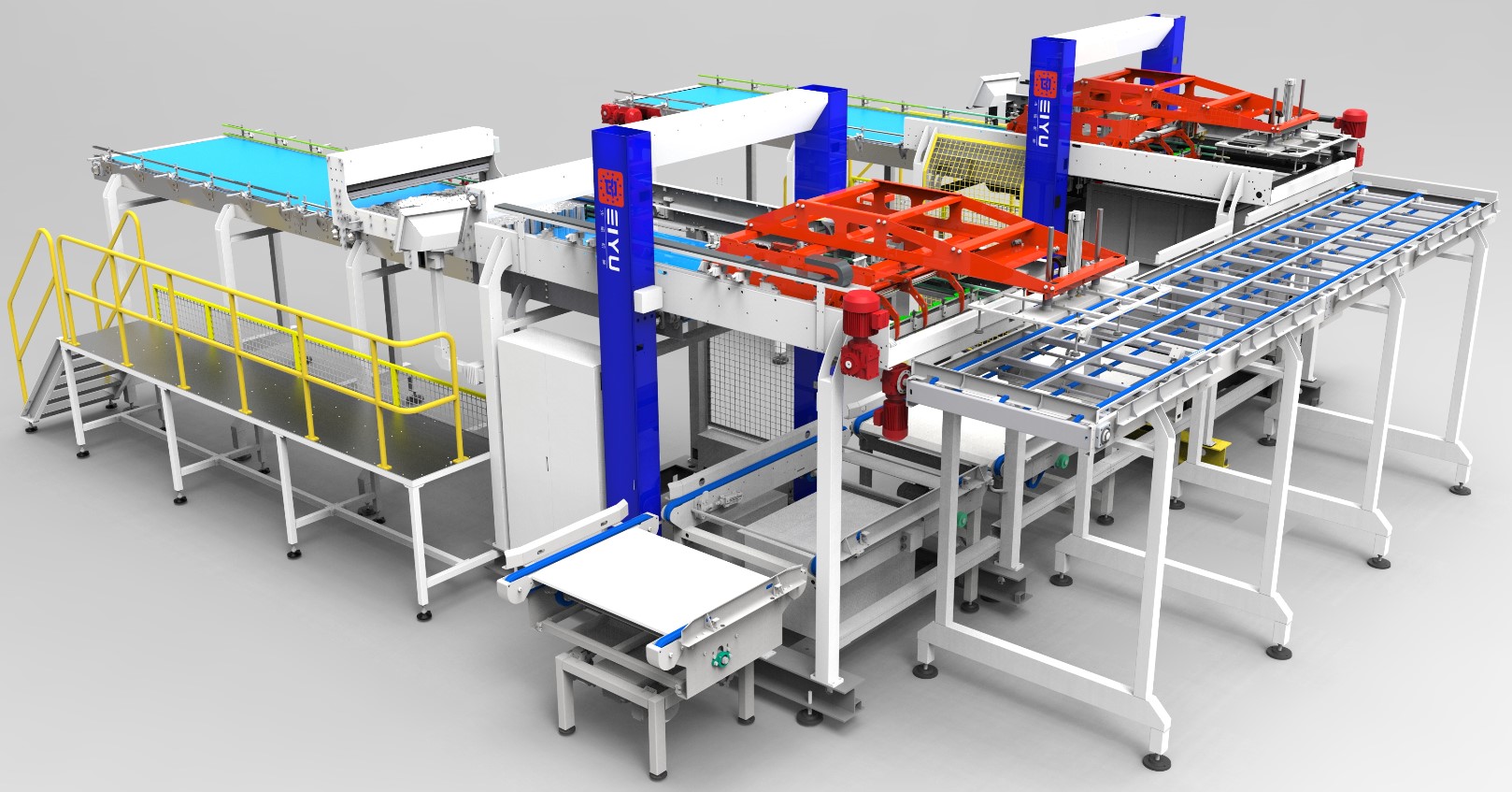

Automatic Juice Drinking Water Packing Machine Loading And Unloading Cage System

Shanghai Peiyu Packaging Technology Co.,Ltd.

1.Introduction to the automatic cage loading and unloading system:

The automatic cage loading and unloading system is the guarantee

for the continuous and efficient operation of the entire

post-sterilization system. It is mainly composed of an automatic

cage loading system, a trolley system and an automatic cage

unloading system.

1) Automatic cage loading system

Function of this system: First, the cage basket conveyor delivers

the cage frame to the cage loading station under the cage loading

host. The hydraulic lifting platform rises to raise the cage frame

bottom plate to the height of the cage loading conveyor line. The

automatic suction and release partition mechanism will suck a

partition and place it on the top of the bottom plate. The bottle

conveying line delivers the product to the cage loading conveyor

line. The bottle pressing device divides the product into layers.

The bottle holding and transferring mechanism holds a whole layer

of the divided product and sends it to the cage frame partition.

The hydraulic lifting platform drops one layer in height, and

repeats this cycle until the whole frame of products is loaded.

This system is automatically controlled by PLC to save manpower and

greatly improve production efficiency.

2) Automatic suction and release partition mechanism

The main frame of this mechanism is placed on the upper part of the

cage loading host and the cage unloading host. The partition

suction fixture reciprocates, and the vacuum generator generates

negative pressure to automatically suck and release the partition.

The positioning device composed of a hydraulic station and a

cylinder and a micro switch is used to sense the correct position

of the interlayer board entering the main lifting platform of the

cage loading room, and automatically complete the accurate

positioning of the next interlayer board when it descends after

each layer of solid bottles is caged.

3) Automatic cage unloading system

Function of this system: First, the automatic trolley delivers the

full-frame product to the cage unloading station under the cage

unloading main machine, the hydraulic lifting platform lifts a

layer of product, the bottle holding and transferring mechanism

holds a whole layer of product and sends it to the cage unloading

conveyor line, the automatic suction and placement of the partition

mechanism will suck a partition and place it at the partition

stacking and lifting mechanism, the hydraulic lifting platform will

drop one layer of height, repeat this cycle until the whole frame

of products is unloaded, and the cage unloading conveyor line will

send the product to the bottle conveying line for secondary

packaging. This system is automatically controlled by PLC to save

manpower and greatly improve production efficiency.

4) Partition stacking lifting mechanism

This system is used to collect partitions and cooperate with the

partition suction mechanism

5) Shuttle car

The cage frames are arranged into a group according to a certain

number and automatically connected by the mechanism (the number of

each group must match the number in the sterilizer), and the

shuttle car will transport the grouped cage frames into (or out of)

each powered sterilizer for subsequent work.

6) Shuttle car positioning control system

The first domestic digital positioning system to be used in China

to ensure that the shuttle car positioning control accuracy is

±1mm. (Company patented technology)

2.Technical parameters:

1) Machine speed: 3 layers/min

2) Installed power: 15Kw

3) Air pressure used: 7bar

4) Air consumption: 1000L/min

5) All hydraulic lifting systems are well-known brands.

Some certification certificates and customer cases:

3.Peiyu electrical configuration:

The configuration principles of electrical components of the

equipment provided by Peiyu in this case are:

| Main configuration | Brand |

| PLC | Beckhoff/Inovance or equivalent brand |

| Touch screen | Weilun |

| Servo motor and controller system | Inovance |

| Frequency converter | Inovance |

| Proximity electronic switch | SICK or equivalent brand |

| Pneumatic components | Festo or equivalent brand |

| Voltage regulator | Festo or equivalent brand |

| Air switch | Schneider or equivalent brand |

| Motor protector | Schneider or equivalent brand |

| Contactor | Schneider or equivalent brand |

| Button | Schneider or equivalent brand |

| Intermediate relay | Schneider or equivalent brand |

| Phase loss protector | Schneider or equivalent brand |

| Terminal | Phoenix |

4.On-site photos of the loading and unloading cage system project case:

5.Quotation and delivery time for Automatic Juice Drinking Water Packing Machine Loading And Unloading Cage System:

(1).Quotation validity period: 1 month;

(2).Payment method: T/T, L/C.

(3).Customers provide the product and packaging samples required

for factory trial free of charge;

(4).Delivery time: 60 working days from the receipt of customer

deposit and product packaging samples.

6.Quality Assurance for Automatic Juice Drinking Water Packing

Machine Loading And Unloading Cage System:

(1).The company guarantees that the goods provided are brand new,

unused, made of the latest design and suitable materials, and meet

the quality, specifications and performance specified in the

technical contract in all aspects;

(2).The company guarantees that after the production line is

properly guided, installed and debugged, the equipment will reach

the various technical performance indicators of the product within

15 days of the entire system being put into operation;

(3).The company guarantees that within the quality assurance period

specified in the contract, it will be responsible for defects,

failures and damages of the production line caused by defects in

the design, process, manufacturing, installation, debugging or

materials provided and the quality of the seller's equipment;

(4).The equipment quality assurance period is 12 months after the

acceptance of the production line. If during the quality assurance

period, it is found that the quality or specifications of the

equipment do not meet the contract provisions, or it is proved that

the equipment is defective (including potential defects or the use

of unqualified materials, etc.), the buyer has the right to propose

rectification to the seller within the product quality assurance

period according to the inspection certificate issued by the

statutory department;

(5).The company guarantees the mechanical properties of the

equipment provided, the quality of the product and the consumption

indicators of the product.

7.Equipment warranty for Automatic Juice Drinking Water Packing

Machine Loading And Unloading Cage System:

(1).After the equipment is accepted, a 12-month warranty is

provided, and the control system (standard Huichuan brand) provides

a 24-month warranty; during the warranty period, our company will

provide users with free spare parts and timely and effective

services (wearing parts are not covered by the warranty);

(2).If the equipment fails and needs to be repaired on site, our

company guarantees that the maintenance personnel will rush to the

customer's site within 48 hours to help the customer eliminate the

fault in time (except for force majeure);

(3).After the warranty period, our company will provide users with

a wide range of preferential technical support, sufficient spare

parts supply and other after-sales services for life;

8.Packaging and transportation for Automatic Juice Drinking Water

Packing Machine Loading And Unloading Cage System:

(1).Packaging method:

The packaging uses new and sturdy special packaging boxes or fixed

frames, which are suitable for long-distance transportation,

moisture-proof, rust-proof, shock-proof, suitable for land

transportation, sea transportation and overall lifting.

(2).Transportation method: land transportation, sea transportation.

|