| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Fully Automatic Packing Machine |

|---|---|

| Brand Name: | EVERSUN |

| Model Number: | QVC |

| Certification: | ISO,CE |

| Place of Origin: | CHINA |

| MOQ: | 1set |

| Price: | negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, MoneyGram, Western Union |

| Supply Ability: | 5000set/year |

| Delivery Time: | within 7-15 work days |

| Packaging Details: | Standard export wooden cases |

| Color: | Customized |

| Weight Range: | 5-50kg |

| Application: | Food, Beverage, Pharmaceutical, Chemical, etc. |

| Features: | Automatic Feeding, Filling, Sealing, and Cutting |

| Machine Material: | Stainless steel |

| Machine Dimension: | L1400 x W1000 x H1700 mm |

| Packing Material: | Plastic, Paper, or other materials |

| Packing Capacity: | Large Capacity |

| Bag Material: | Laminated Film, PE, PP |

| Control System: | PLC Control |

| Power Consumption: | 3KW |

| Key Words: | Automatic packaging machine |

| Company Info. |

| EVERSUN Machinery (Henan) Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

![]()

This equipment is specially designed to meet market demand, with a high degree of

automation (computer intelligent automatic recognition, no need for complex and

cumbersome lever weighing system), simple operation, only the worker needs to insert

the bag (no manual movement of the gate action) to complete the packaging production

process, saving, reducing the labor intensity of workers, greatly reducing production

costs, and improving production efficiency.

![]()

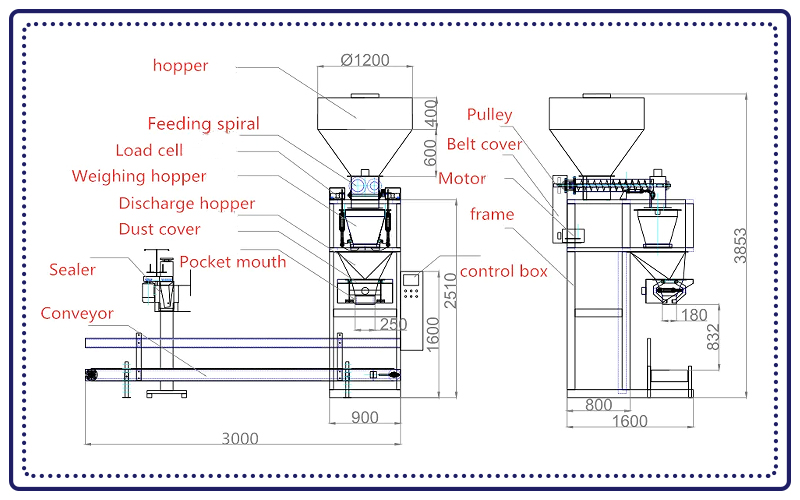

Main components and their functions

Pneumatic Clamping Device and Bracket: Mounted on the load cell, it is used for rapid and

slow filling of materials.

Weigh System: A high-speed response weighing system is adopted to ensure packaging

accuracy.

Servo Motor: Drives the lifting of the tray, the lifting speed can be arbitrarily, and there is almost

no dust during filling, reducing environmental pollution.

PLC Control and Human-Machine Interface: PLC control is adopted, and the touch operation

is simple, making it easy for users to get started quickly.

Workflow

1. Manual bagging or canning: The preparation work begins.

2. Container elevation: Elevate the container to an appropriate position.

3. Rapid filling: Start rapid filling of the material.

4. Container descent: The container gradually descends during the filling process.

5. Weight reaches pre-set: When the weight reaches the pre-set value, enter the slow filling stage.

6. Weight reaches target value: Once the final weight reaches the set target value the filling is

completed.

7. Manual removal of the container: Finally, the packaged container is manually removed.

![]()

![]()

1. The pneumatic bag clamping device and the rack are installed on the weight sensor,

and they perform rapid and slow filling according the pre-set weight.

2. The high-speed response weighing system ensures high packaging accuracy.

3. The servo motor drives the tray to move up and down, the lifting speed can be set arbitrarily.

There is basically no dust pollution during filling.

4. The servo motor and servo drive control the screw, ensuring stable performance high

accuracy.

5. PLC control and touch screen human-machine interface display make operation simple.

6. Pneumatic bag clamping devices and can clamping devices available. By choosing different

devices, the requirements for canning and bagging can be met.

7. Two working modes can be switched: fixed quantity mode or-time weighing mode. The fixed

quantity mode is faster but less accurate, while the real-time weighing mode is more accurate but slower.

| Metering Mode | Auger filling, Loading cell |

| Package Weight | 5kg / 10kg / 15kg / 20kg / 25kg / 50kg or customized |

| Materials | SS304 / SS316L / Carbon steel |

| Package Accuracy | ±0.2-1%(according to the material) |

| Packaging Speed | 2-10bags/min(according to the material) |

| Power Supply | 220V,380V,480V or customized |

| Hopper Volume | 50L |

| Total Power | 5Kw |

| Overall Dimensions | 1000×900×2150mm or customized |

| Operational Style | PLC control system,Colorful touch screen |

![]()

![]()

![]()

The automatic weighing and packaging machine for powders is mainly used for materials

that require precise weighing and packaging. The specific fields of its application as follows:

1. Food industry: Suitable for packaging starch, flour, vegetable fat powder, baking powder,

cake powder, corn starch, milk tea powder.

2. Chemical industry: Suitable for waterproof coatings, putty powder, lime powder, lithium-ion

battery powder, lithium iron phosphate, etc.

3. Agricultural: Suitable for organic fertilizer, foliar fertilizer, chemical fertilizer, water-soluble

fertilizer, etc, in powder packaging.

4. Other fields: Also includes medicine, additives, feed, water-soluble fertilizer, sugar,

monosodium glutamate, solid beverage, solid medicine, dye, flavor and fragrance,

in powder and granular materials for weighing and filling.

![]()

![]()

![]()

We have been specializing in the production of Screening and conveying equipment for

13 years. China's vibrating screen industry top three. And we have done matching and

OEM for many large companies. Including the world's top vibrating screen manufacturer,

Sweco, USA, we have OEM for his China region. And our products are often exported to

Australia, Thailand, Indonesia, New Zealand and other countries.

We welcome customers or dealers to visit our factory and will

arrange everything for you.

Our factory address: West of the industrial and commercial office

of Da Zhaoying Town,

Xinxiang City, Henan Province.

|