| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | CO2 Laser Vision Controller |

|---|---|

| Brand Name: | RUIDA |

| Model Number: | RDV6445GT5 |

| Certification: | CE FCC ROHS |

| Place of Origin: | Mainland China |

| MOQ: | 50 |

| Price: | Negotiable - Inquire Within |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Delivery Time: | 5-8 work days |

| Packaging Details: | Carton Packing |

| Brand: | RUIDA |

| Model: | RDV6445GT5 |

| Laser source: | CO2 glass tube, CO2 RF tube and UV lasers |

| Feeding: | U axis feeding/ Y and U axes feeding synchronously, sheet feeding/large format segmentation feeding |

| Double heads synchronous: | Support |

| Communication: | Ethernet, USB and WIFI (optional) |

| Cutting function: | Feature positioning, Mark point positioning |

| Engraving: | Plane engraving, slope engraving and gray engraving |

| Operating system: | WinXP, Win7, Win8, Win10, 32-bit or 64-bit |

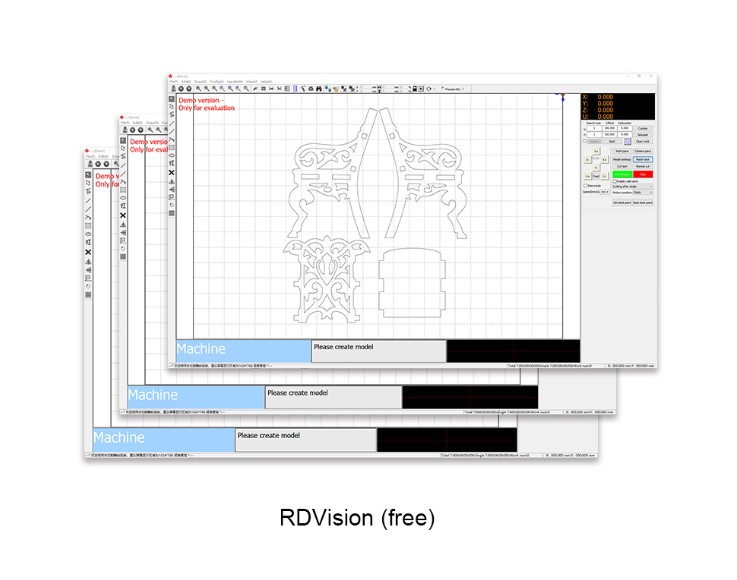

| Software: | RDVision,RDCMarkVision ,RDWorksV8、RDImage |

| Company Info. |

| Shenzhen Ruida Technology Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

RDV6445GT5 High Precision Positioning CO2 Laser Controller for Feature Recognition and Mark Point Auxiliary Positioning

Key functions and features:

• Full Functionality: Supports all functions of the standard controller.

• High Precision Positioning: Ensures precise positioning for various applications.

• Feature and Mark Point Recognition: Supports the recognition and positioning of feature points and auxiliary mark points.

• Vision Cutting: Enables mark point vision cutting for more accurate cutting operations.

• Irregular Materials Cutting: Allows matching and cutting of irregular materials.

• Projection Cutting: Supports projection cutting for enhanced flexibility in operations.

Precision and Accuracy: With high precision positioning, our technology enhances the accuracy of feature recognition and Mark point positioning, reducing errors in operations.

• Versatile Cutting Solutions: Our vision cutting capabilities allow for efficient handling of irregular materials and various cutting methods, providing flexibility for diverse applications.

• Enhanced Efficiency: The combination of precision positioning and advanced cutting techniques leads to improved productivity and reduced material waste.

.

|