| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Multi Cavity Injection Moulding |

|---|---|

| Brand Name: | Howe |

| Model Number: | HW-898 |

| Place of Origin: | Dong guan |

| Certification: | SGS,TUV,ISO9001 |

| MOQ: | 1 |

| Price: | 2000-10000 |

| Packaging Details: | Wooden Box Packing |

| Delivery Time: | 20-25days |

| Payment Terms: | TT |

| Supply Ability: | 35Set/month |

| Mould Base: | Standard |

| Surface Finish: | Smooth |

| Product Name: | Multi Cavity Injection Moulding |

| Mould Life: | Long |

| Mould Standard: | DME/HASCO/LKM |

| Mould Steel: | P20/H13/718/2738 |

| Size: | Customized |

| Material: | Plastic |

| Product Name | OEM custom injection mould for keyboard keycaps set |

| Metal Material | Aluminium, Steel, Stainless steel, Copper, Magnesium, Cast iron, Zamak, etc |

| Plastic Material | ABS,PC,POM,PMMA,NYION,ABS+PC,PBT,PBT+GF30,PPS,PPS+30GF,PA6+GF30,PEEK,PEI,Bakelite. |

| Color | Customized (painting or anodizing) |

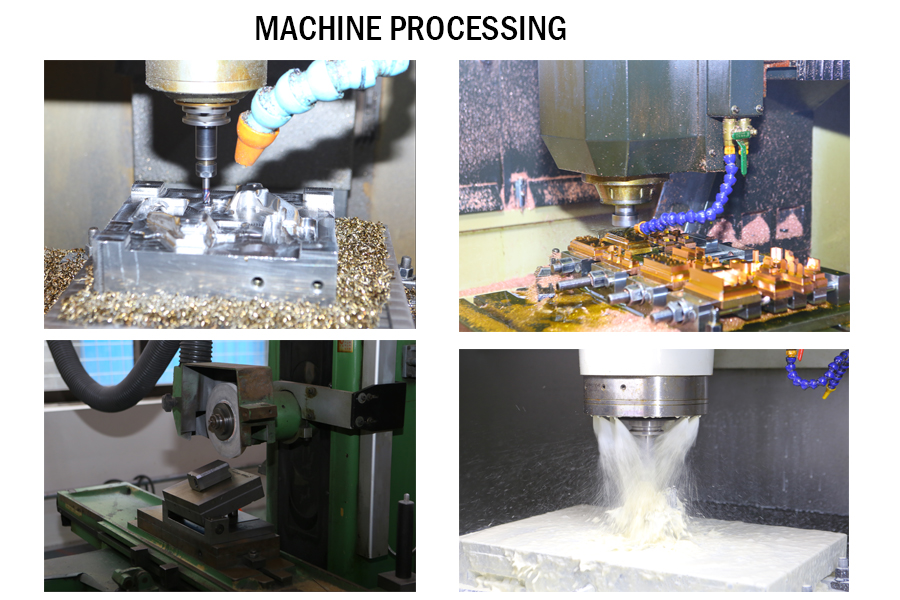

| Process | CNC Turning, Drilling, Milling, Punching..... |

| Tolerance | +/- 0.01~+/-0.05 |

| Surface Treatment | Smooth, Polishing, Painting, SandBlasting, Electroplate, Silk-screen, Laser Etching, Anodizing,Brushing |

| CNC Machines | 20 |

| Shipping Packing | Wood case or carton box |

| 1. With plastic bag, with pearl-cotton package | |

| 2. To be packed in cartons or wood case | |

| 3. Use glass tape to seal cartons, or pin tight the wood case with nails. | |

| 4. Deliver out by DHL, FEDEX | |

| Or according to the customer‘s requirement. |

1. Plastic injection molding parts for architectural parts

2. Plastic injection molded auto components

3. Injection-molded household utility products

4. Plastic molded electronic enclosures

5. Plastic molds for medical & dental products

6. Injection molding parts for model shops, toys

7. Injection plastic parts for new product design & development

8. Custom plastic parts for construction

9. Injection plastic parts for others like cosmetic case

10. Plastic injection for Information Technology

11. Molded plastic parts for payment system

12. Precision plastic parts for Agricultural equipment

1> Here in our factory and company, quality is our culture, it

means everything.

2> Time is gold, we will offer you efficient and professional

service and recommendation.

3> You are so welcome to come to us for business cooperation, as

good as friends making and communication.

4> Customer satisfaction is our wheels of progress, after-sales

service is a focus.

About Us

HOWE Precision Mould Manufacture Co., Ltd. private-owned

enterprise, with around 2, 000sqm work shop locates in Chang'an

Town, Dong Guan City, Guang Dong Province, China. Which was

established at the beginning of 2010 and it′s only one and a half

hour′s drive from the airport/ ferry port in Hong Kong, Guang Zhou

and Shen Zhen to our factory. Our moulds are mainly exported to

USA, Canada, Brazil, UK, Germany, Spain and Japan etc.,

1> Usually, your goods will be packaged in plastic bags,

anti-shock foam, cartons, waterproof and environmental adhesive

tape. For other individual demand in packaging, please specify in

communication.

2> Unless specially asked for:

We choose DHL, Fedex for small package; ( 3-7 days )

UPS, TNT and Air Lift for big package. ( 7-11 days )

Personal offical express account and forwarder are all good.

For cheap shipping way and within 2kg, E-Post ( 7 days ) and China

Post Air Mail ( 30 days) are available.

3> Usually non-custom process goods can be delivered in 3-5

days; custom process goods can be delivered in 7-30 days. Please

consult for professional advise.

A1: More often than not, part complexity will dictate whether you need to use one process or the other. Parts that can be pressed into the desired shape can be accomplished through compression molding. Parts that are more complex, that have features that require a more sophisticated mold and will be more repetitive in its' production cycle are better injection molded

A2: - Sample photo with size or 2D/3D design

- Cavity quantity

- Runner type, cold or hot

- Mould steel type: P20, 718, 2738, H13, S136, 2316, etc.

- Injection machine parameter or plate size(tie rod distance)

A3: The Place of Origin of Multi Cavity Injection Moulding is Dong guan.

A4: The Certifications of Multi Cavity Injection Moulding are SGS,TUV,ISO9001.

A5: The Minimum Order Quantity of Multi Cavity Injection Moulding is 1.

A6: The Price of Multi Cavity Injection Moulding is 2000-10000.

A7: The Packaging Details of Multi Cavity Injection Moulding is Wooden Box Packing.

A8: The Delivery Time of Multi Cavity Injection Moulding is 30-45days.

A9: The Payment Terms of Multi Cavity Injection Moulding is TT.

A10: The Supply Ability of Multi Cavity Injection Moulding is 35Set/month.

|