| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | DPF DOC SCR |

|---|---|

| Brand Name: | Sanhe |

| Model Number: | sh103M |

| Certification: | 16949 |

| Place of Origin: | China |

| MOQ: | 10pcs |

| Price: | 18-30per liter |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 100000 per month |

| Delivery Time: | 5-8 days |

| Packaging Details: | carton/pallet |

| Material: | metallic foil+PGM coating |

| cpsi: | 300cpsi,400cpsi,500cpsi,600cpsi |

| name: | SCR Selective Catalytic Reduction Catalyst,400cpsi metalic substrate |

| keyword: | scr catalyst |

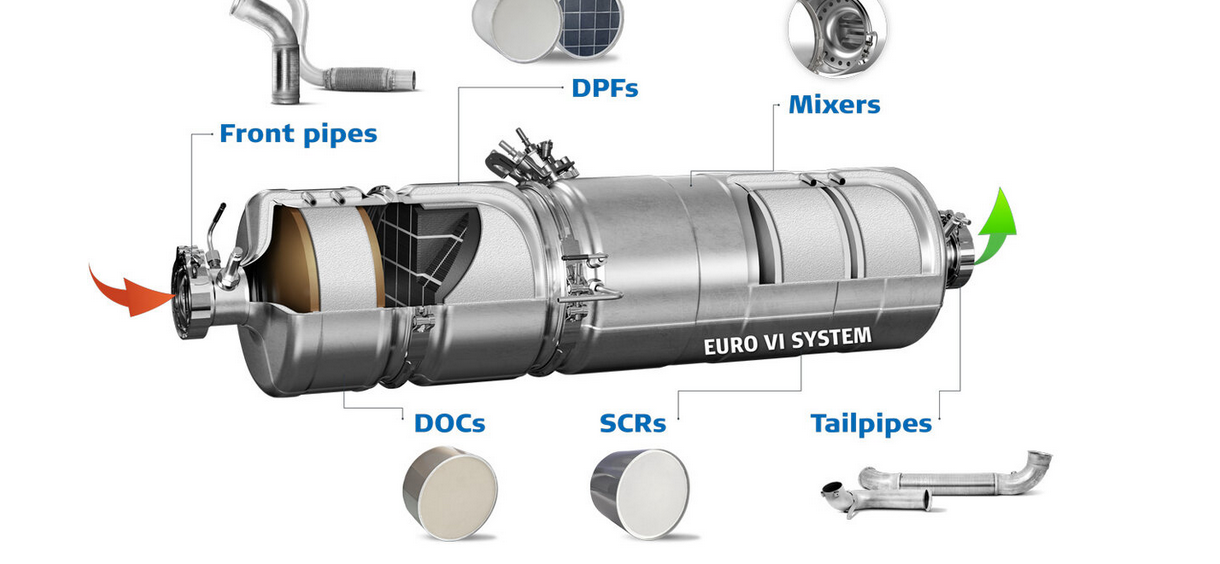

The primary function of the SCR catalyst in a Diesel ATS is to convert harmful nitrogen oxides (NOx = NO + NO2) in the exhaust gas to nitrogen and water. The SCR reaction takes place at the catalyst surface in the presence of NH3 which is generated from AdBlue®/DEF (solution of 30% of Urea in water) upfront the SCR catalyst.

Dinex has a variety of SCR catalyst technologies that can be selected based on specific application conditions and ATS temperature levels. Typically, titanium-vanadium based technologies are suitable for applications, where the exhaust gas temperature is not exceeding 550°C level. The Cu-SCR technology is designed for high DeNOx functionality at low temperatures and the Fe-SCR technology is suitable for conditions where the exhaust temperatures exceed 600°C.

Advanced emissions regulations like EuroVI / EPA10 / China N6 / Bharat S6 need more than 95% NOx conversion levels and the Dinex Cu-SCR technology achieves conversion levels well above this limit.

This SCR technology is typically characterized by high NOx conversion activity in a wide temperature window with very low NH3 oxidation at high temperatures which ensures optimal AdBlue®/DEF utilization.

|