| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

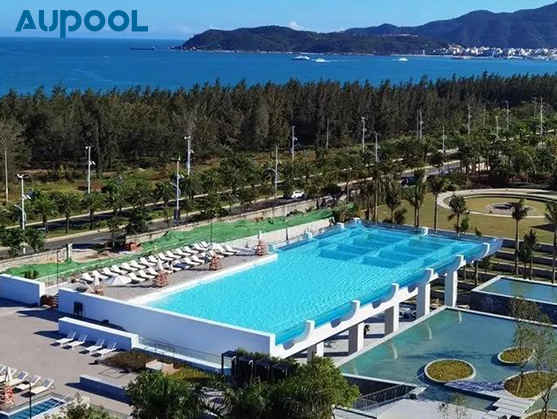

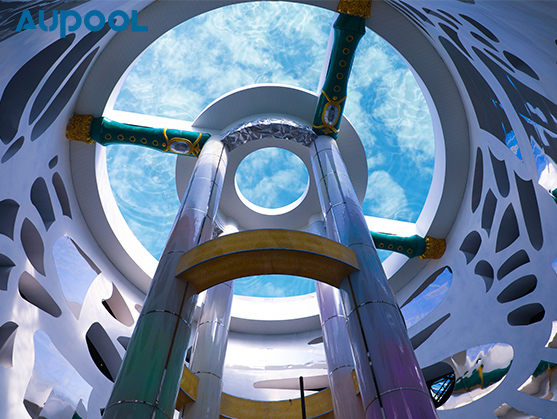

| Categories | Acrylic Panels For Swimming Pool |

|---|---|

| Place of Origin: | Guangdong, China |

| Brand Name: | Aupool |

| Model Number: | Aupool -infinitive pool |

| Type: | Pool |

| Thickness: | 30mm-950mm |

| Materials: | PMMA, Acrylic,lucite |

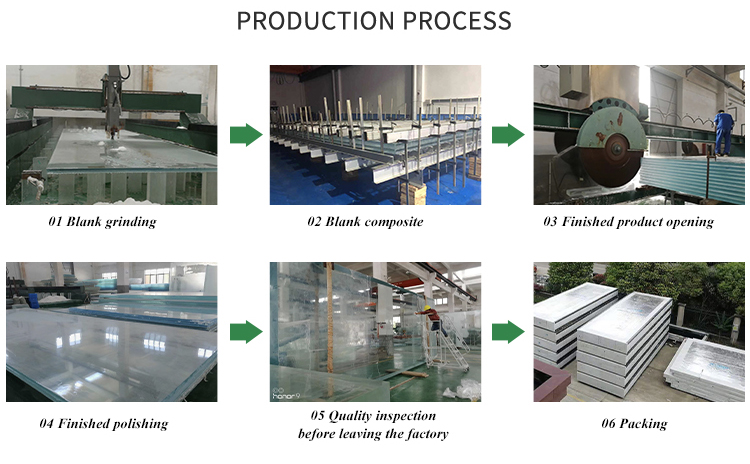

| Process: | Dry constant temperature polymerization |

| Density: | 1.20g/cm3 |

| Application: | Swimming pools and so on. |

| Shape: | Customer's Demand |

| Light transmission: | High light transmission(95%) |

| Warranty: | Not yellow and crack for 30 years outdoors |

| Surface: | High Surface Hardness |

| Resistant: | Excellent resistance to weather |

| Packaging Details: | 1. Covered with craft paper or PE film on double sides with a pallet 2. Bulk cargo packing: 2 tons per tray, use wooden pallets on the bottom, with packaging film packages all around to ensure transportation security. 3. Full container load packing: |

| Port: | Guangdong Shenzhen |

| Supply Ability: | 100000 Square Meter/Square Meters per Month |

| Price: | $273.00/square meters |

| MOQ: | 1pc |

| Company Info. |

| HuiZhou AUPOOL Technology Co.LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

Material | Lucite Acrylic |

Thickness | 30-950mm customized |

Color | Clear/transparent |

Surface | High Surface Hardness |

Light transmission | High light transmission(95%) |

Diaphaneity | More than 93% |

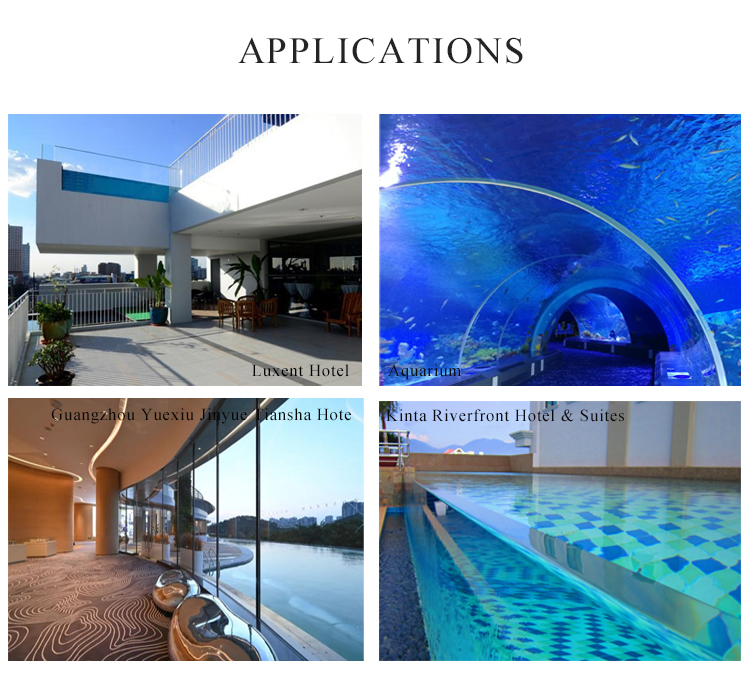

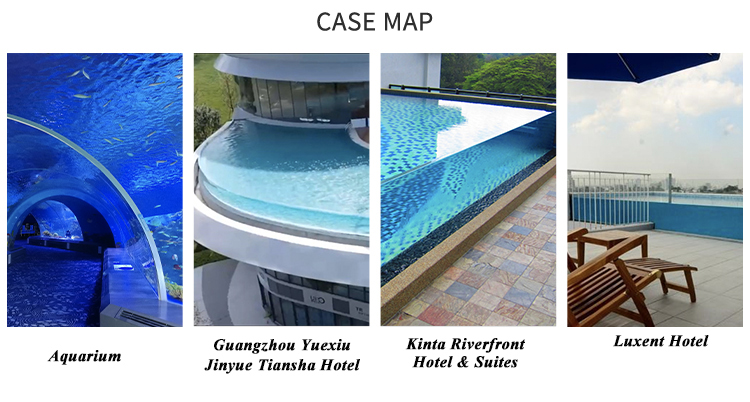

Application | undersea world, Oceanarium, Zoo, Luxurious hotels, Swimming pools

and so on. |

Density | 1.20g/cm3 |

Application | Swimming pools and so on. |

Shape | Customer's Demand |

Light transmission | High light transmission(95%) |

Warranty | Not yellow and crack for 30 years outdoors |

Surface | High Surface Hardness |

Resistant | Excellent resistance to weather |

NO. | Physical Property | ISO | Unit | Result | ||||

1. | Specific gravity / density | D792 | Kg/m | 1175 | ||||

Optical | ||||||||

2. | Luminous Transmittance | GB/T2410-2008 | % | 92.6 | ||||

3. | Haze | GB/T2410-2008 | % | 1.8 | ||||

Mechanical | ||||||||

4. | Tensile Strength | 527-2:2012 | ||||||

a) Maximum tensile strength | MPa | 80.7 | ||||||

b) Elongation at break | % | 4 | ||||||

c)Tensile modulus | MPa | 3010 | ||||||

5. | Flexural Strength | 178:2010 | ||||||

a) Maximum flexural strength | MPa | 87.7 | ||||||

b) Maximum flexural strength | MPa | 2900 | ||||||

6. | Comintsane Yield Stress | 604:2002 | MPa | No Yield Point | ||||

7. | Izod Notched Immpact Stress | D256-10 (Method c) | J/m | 8 | ||||

8. | Shear Strength | D732-10 | MPa | 62.5 | ||||

9. | Rockwell Hardness | 2039-2:1987 | HRL | 105 | ||||

Thermal | ||||||||

10. | Flammability | UL94-2013 (7) | mm/min | 24.1 | ||||

11. | Heat Deflection Temperature | 75-2:2013(Method B) | °C | 106.2 | ||||

12. | Glass Transition Temperature | 11357-2:1999 | ||||||

a)Teig | °C | 105.6 | ||||||

b)Tmg | °C | 114.0 | ||||||

c)Tefg | °C | 122.3 | ||||||

13. | Coefficient of Linear Thermal Expansion | 11359-2:1999 | °C | -40 to 110 | ||||

a)Parallel to flow | um/m-°C | 78.60 | ||||||

b)Perpendicular to flow | um/m-°C | 80.56 | ||||||

Others | ||||||||

14. | Water Absorption | 62:2008 | % | 0.12 | ||||

15. | Odor | None | ||||||

16. | Taste | None | ||||||

|