| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | CNC Copper Parts |

|---|---|

| Brand Name: | Yexin |

| Model Number: | CP63 |

| Certification: | ISO9001:2015 |

| Place of Origin: | Dongguan, China |

| MOQ: | 1 pcs |

| Price: | Negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, Paypal |

| Supply Ability: | 183000 pcs/month |

| Delivery Time: | 3-12 work days |

| Packaging Details: | Standard Export Carton, Wooden Case, etc. |

| Application: | Aerospace, Automotive Industry, Consumer Electronics, Medical, etc. |

| Material: | Copper |

| Processing: | CNC Turning, Milling, Broaching, Drilling, etc. |

| Service: | OEM, ODM |

| Equipment: | CNC Machining Centers |

| Tolerance: | ±0.01mm-0.005mm, etc. |

| Drawing Format: | CAD, PDF, STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, etc. |

| Micro Machining or Not: | Micro Machining |

| Keyword: | CNC Copper Parts |

| Company Info. |

| Dongguan Yexin Intelligent Technology Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

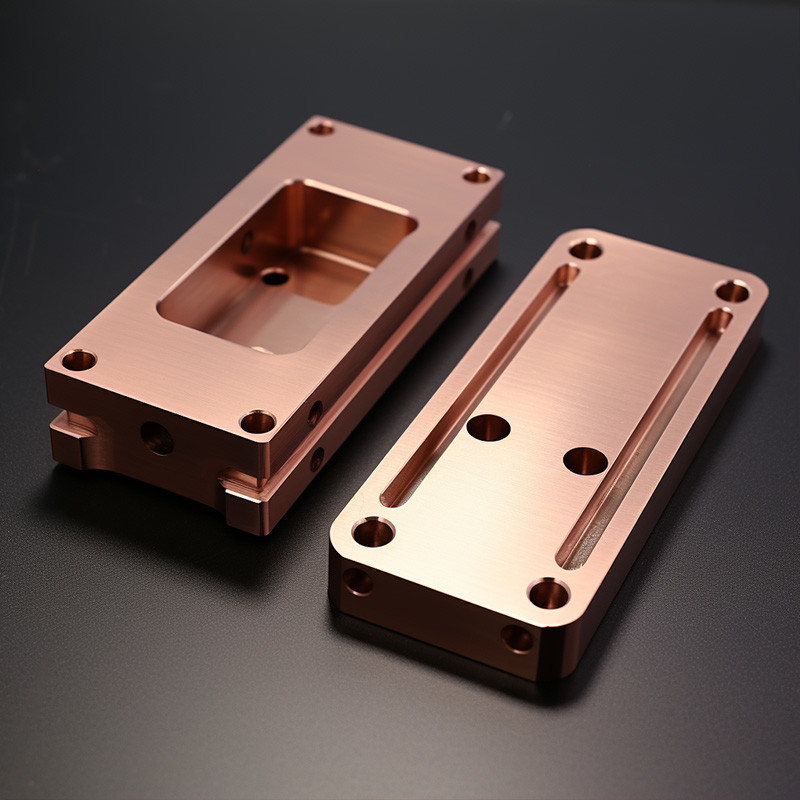

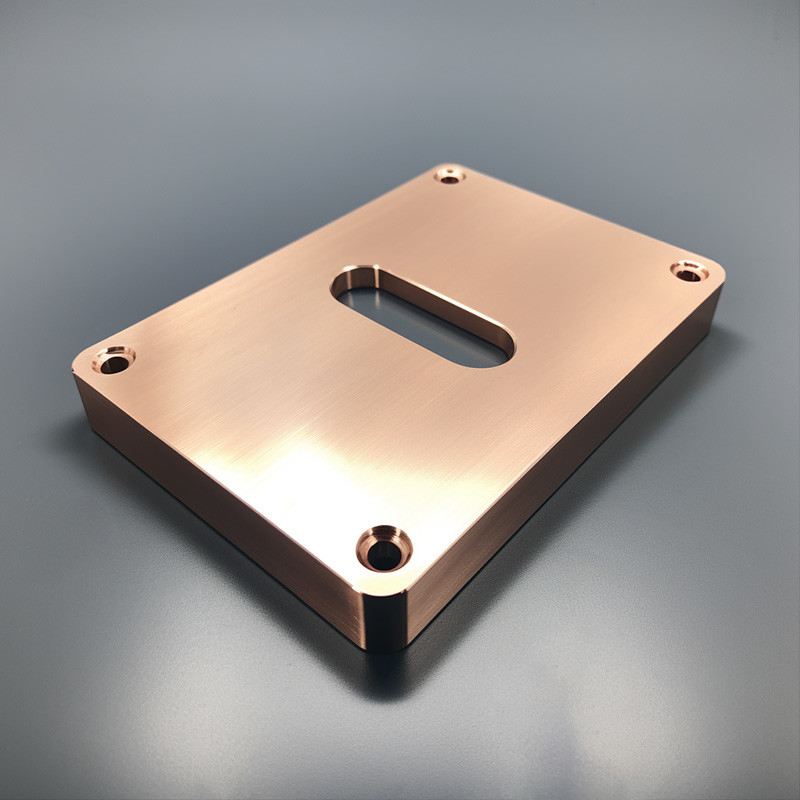

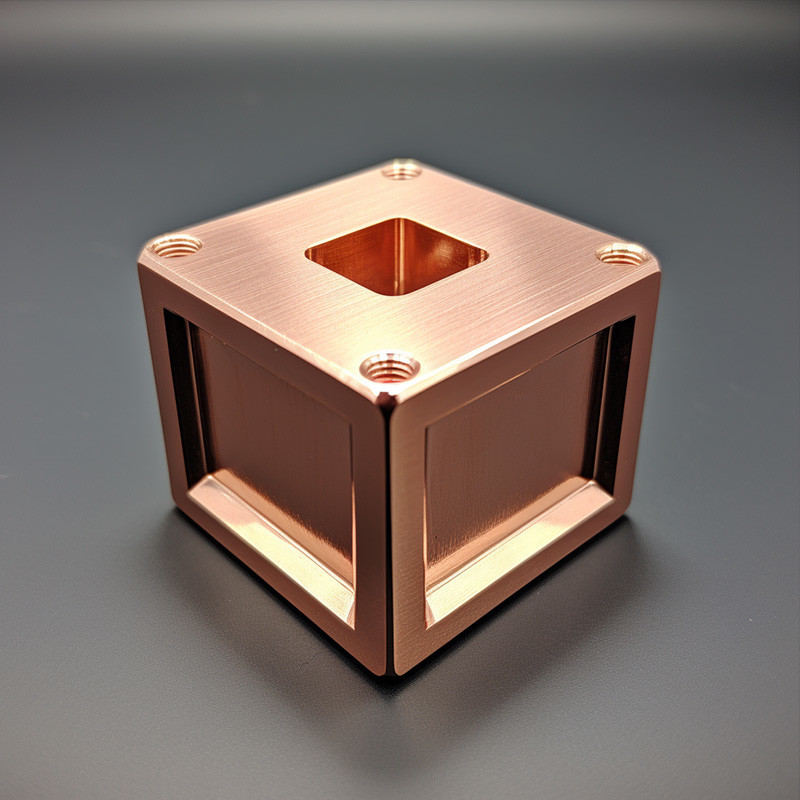

Custom Precise Machining CNC Part Odm CNC Machining Parts Milling Copper

CNC Lathing Parts

CNC machining is presently the prevailing subtractive manufacturing technology, offering a

highly adaptable and sturdy method for crafting tailored metal and plastic components.

Employing CAD models, CNC machines meticulously eliminate material from a solid block using

various cutting tools.

In essence, CNC machining yields components with precise tolerances and remarkable material

characteristics. It is well-suited for individual projects and moderate-volume production

(up to 1,000 parts) owing to its exceptional repeatability.

Nevertheless, it entails more design constraints compared to 3D printing, partially attributable

to the subtractive nature of the technology.

Product Details

| Common Copper Materials | |

| No. | Properties |

| Copper C110 | Copper (C110) is a pure at 99.90% copper alloy, with universal for electrical applications high thermal conductivity and good corrosion resistance. |

| Copper C101 | Copper (C101), 99.99% pure, is a copper alloy with excellent conductivity and high corrosion resistance and toughness. |

We specialize in the production of custom-made products and offer

surface treatment services

tailored to meet our customers' specific requirements and industry standards.

Our comprehensive solutions are both efficient and cost-effective, making us a one-stop

destination with the capacity and capability to provide integrated services.

| Name | Machining Marks |

| As machined | Visible, light surface scratches |

| Smooth machining | Visible, light surface scratches |

| Fine machining | Slightly visible |

| Polishing | Removed on primary surfaces |

| Bead blasting | Removed for non-cosmetic, removed on primary surfaces for cosmetic |

| Brushing | Reduced for non-cosmetic, removed on primary surfaces for cosmetic |

| Powder coating | Removed |

CNC Machining Applications

CNC machining finds extensive applications across various industries.

It is prevalent in sectors like aerospace, automotive, consumer electronics, robotics,

agriculture, and others that rely on metal components.

Additionally, CNC machining plays a significant role in medical devices, household products,

energy, oil and gas, as well as various consumer-oriented applications.

It stands as one of the most widely adopted manufacturing processes

globally.

Company Profile

FAQ's

1. What formats of the files can you accept?

We can accept most of the 3D file formats like SolidWorks

(.sldprt)/ ProE(.prt) / IGES(.igs) /

STEP (.stp). We can also use 2D drawing (.pdf) or AutoCAD (.dwg) for quote against the parts

with simple structure.

All the other files formats are not listed above but can be read in AutoCAD/ProE/SolidWorks/ will

be also fine for us.

2. How can I ensure my design is confidential?

We can sign the NDA (Non-disclosure Agreement) with our customers

before quoting or placing

an order.

3. How does compare to other suppliers in terms of price?

While direct comparisons can be challenging, We generally offers

prices that are typically 25-45%

lower for plastic injection mold tools and CNC machined/turned parts when compared to suppliers

in North America and Europe.

In contrast to Chinese suppliers, our strategy is not to compete

solely on price. Instead,

we prioritize delivering the highest levels of quality, swift response times, and professional results.

4. What is the turnaround time for receiving my parts?

High-quality parts can be manufactured in as little as two weeks if

you furnish us with

comprehensive 2D and 3D CAD models. However, more intricate parts with special features or

requirements may necessitate a longer production time. To obtain more precise lead times

tailored to your project, please request a quote.

Regarding shipping, the majority of our shipments are handled via air freight, taking a few days

for delivery from China to Europe or North America.

|