| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Purlin Roll Forming Machine |

|---|---|

| Brand Name: | CHBEST |

| Model Number: | YX-300 |

| Certification: | CE,BV,SGS |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | USD15000-USD36500/set |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 20sets/month |

| Delivery Time: | 5-60days |

| Packaging Details: | 20GP/40GP container |

| Name: | Manual Adjustable 3mm Thickness C Purlin Roll Forming Making Machine |

| Color: | As your request |

| Customized: | Yes |

| Material: | Galvanized |

| Warranty: | 2 years |

| Cutting Type: | Hydraulic |

| Condition: | New |

| Use: | Roof |

| Voltage: | 380v |

| Production Capacity: | 15m/min |

| Company Info. |

| Cangzhou Best Machinery Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Manual Adjustable 3mm Thickness C Purlin Roll Forming Making Machine

Features of C Purlin Roll Forming Machine

The C shaped purlin formed by C purlin roll forming machine has

excellent anti-bending property and are easy to install. Machine

adopt cast iron structure, which will increase the strength of the

machine.

The processing of Punching & Cutting has different type for

choosing: Post-Punching & Post-Cutting, Pre-Punching & Post

Cutting, Pre-Punching & Pre-Cutting.

Applications of C Purlin Roll Forming Machine

The finished products are widely used as the supporter of roof and

wall in large-scale and mid-scale construction, such as factory,

warehouse, garage, exhibition center, cinema, theatre, garden and

so on.

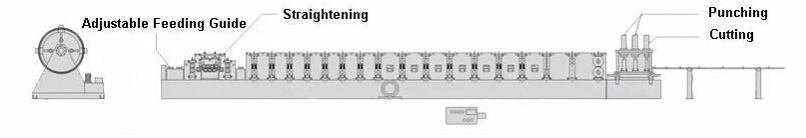

Process Flow of C Purlin Roll Forming Machine

Uncoiler --- Feeding --- Straightening --- Roll Forming ---Punching---Cutting--- Output table

Technical Detail

| Weight capacity of decoiler | 3.5T |

| Appearance Size(L*W*H) | 6500*800*1600 |

| Raw material /feeding sheet material | colored steel & galvanized steel |

| Roller material | cr15 high grade steel |

| Shaft material | cr15 high grade steel |

| Kind of drive | chain drive |

| Cutting system | automatic hydyaulic cutting |

| Cutting blade material | Cr 12 high grade steel |

| Frame material | 300 H-high grade steel |

| Control system | totally automatic PLC control system |

| Main power | 18.5 kw |

| Roller stations | 13-18 rows |

| Speed of production | 8-12m/min |

| Thickness of colored steel | 1.5-3mm |

Electric Components

| Suitable Power | 380V, 50 Hz, 3 phase or according to your need. |

| Screen | 7 inch touch screen, easy to operate. |

| PLC | Delta DVP14ES |

Well-adapted to various conditions, such as moisture, electromagnetic disturbance. | |

| Frequency Converter | Delta VFD-M. It has the advantage of slowing down before cutting, to ensure the length accuracy (±1mm, far better than industrial standard ±3mm). |

Length Measurement Device | Omron, made in Japan. |

| It features with high accuracy and stability. |

Machine pictures:

Packing and Loading:

1. One 40ft container for loading one set machine with manual decoiler;

2. The whole Wiped Anti Rust Oil, PLC controller covered by foam film;

3. Spare parts and some small parts packed in plastic tooling box;

4. All Components Fixed by steel wire with Container.

After-sale Serive

- The seller take responsibility to installation and commissioning

of the equipment and free training. After machine arrive the

destination, by the request of the buyer , the seller will provide

1 technical engineer to guide installation and training , and the

buyer should give the technical person with full cooperated.

- Installation period: about 5 days after the complete preparation

by the buyer such as the foundation and all necessary accessories.

- Training time: 5 days.

- Before departure of the engineers from seller, the buyer should

pay for installation and commissioning fee 100$/day to the point

account of the seller. The two-way ticket,visa, food, hotel , the

translator and insurance are all should provide by buyer with full

responsibility.

-The seller supply technical data (including forming mould drawing,

electrical elements drawing and equipment drawing etc.)

Our advantage:

Over 20 years' rich experience!

a.Specialized in roll forming machine since 1998.

b.Keeping improving the quality.

2. Low price

Save your money from every part!

a. Low labor cost;

b. Convenient transportation;

c. Complete supporting industries.

3. PLC

Ensuring high accuracy and easy to operate!

Full Automatic: Just input length of the sheets and numbers of the piece you need, then the machine will start to work as your order.

4. OEM / ODM

Customers’design, color & logo are also accepted!

Our specialized experts and skilled workers keep devoting their hard working to ensure the machine with high quality.

5. One-Years warranty, whole life service

Keep troubles far away from you!

Within the One-YEAR period, we could supply you the replacement parts free of charge for any damaged parts caused by quality problems .

|