BH93420-I WATER LEVEL TRANSMITTER

Introduction:

BH93420-I Sumersible liquid level transmitter/ water level

transmitter that uses HT series diffused silicon isolation oil-filled core as its signal measuring element. It is

designed with a full stainless steel housing and a compact one-piece structure. The

sensing part of the transmitter that is immersed in the water is completely sealed

with stainless steel, ensuring excellent waterproof performance. The product has

undergone rigorous high and low-temperature compensation and aging tests,

resulting in high reliability and excellent stability.

Product Features:

1. Full stainless steel housing, suitable for various testing

environments

2. Immersion-type probe measurement, easy installation

3. Diverse output signal options

4. Explosion-proof marking: ExiaIICT6

5. High protection rate: IP68

6. PE or PU cable

Applications:

1. Compatible with 316LSS,noncorrosive liquids

2. Monitoring water levels in various applications such as sewage,

industrial and municipal water, water tanks, wells, rivers,

seawater, lakes, etc

3. Measuring fuel levels in diesel and fuel tanks

Performance Parameters:

| Measurement Range | 0~10m…400m |

| Overload | ≤ 2 X of rated range |

| Accuracy @ 25ºC | ±0.25% (Typ.) ±0.5% (Max.) |

| Repeatability | ±0.03% (Typ.) ±0.05%FS (Max.) |

| Hysteresis | ±0.03% (Typ.) ±0.05%FS (Max.) |

| Long-Term Stability | ±0.2%F.S/year (Max.) |

| Zero Point Temperature Drift | ±1.5%F.S(Typ.) ±2%F.S (Max.) |

| Full Scale Temperature Drift | ±1.5%F.Sr(Typ.) ±2%F.S (Max.) |

| Compensation Temperature | 0-50ºC (0-1m. 0-2m ); 0-70ºC |

| Operating Temperature | -20~80ºC |

| Storage Temperature | -30~100ºC |

| Vibration | 10g,55Hz ~ 2kHz |

| Housing Material | 1Cr18Ni9Ti |

| Diaphragm Material | 316L Stainless Steel |

| Insulation Resistance | >=100MΩ@100VDC |

| Explosion-proof Rating | ExiaIICT6 |

| Protection Rating | IP67, IP68 |

| O-Ring Seal | Fluoro rubber |

| Weight | ~0.3Kg (without cable) |

| Cable Material | Polyethylene, Polyurethane |

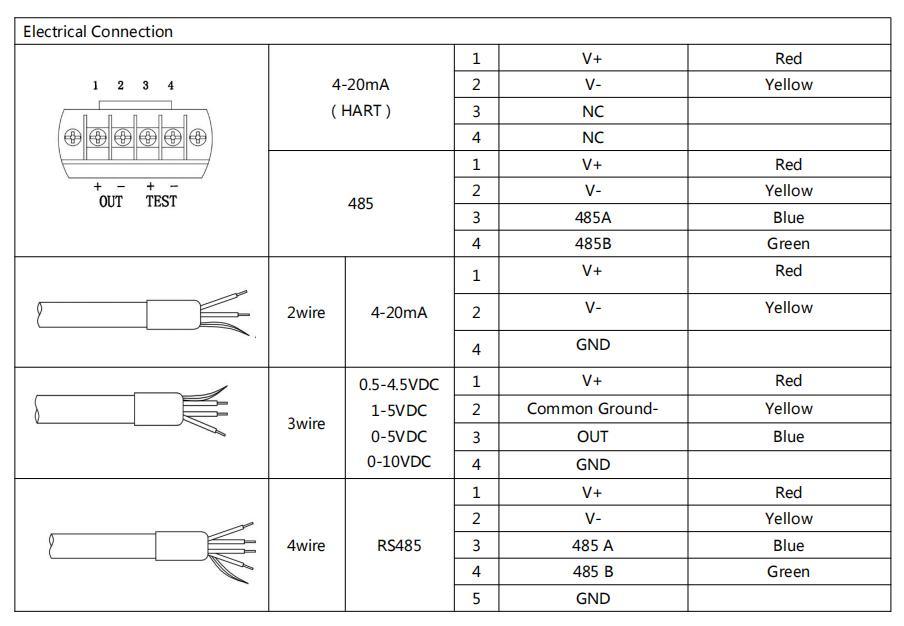

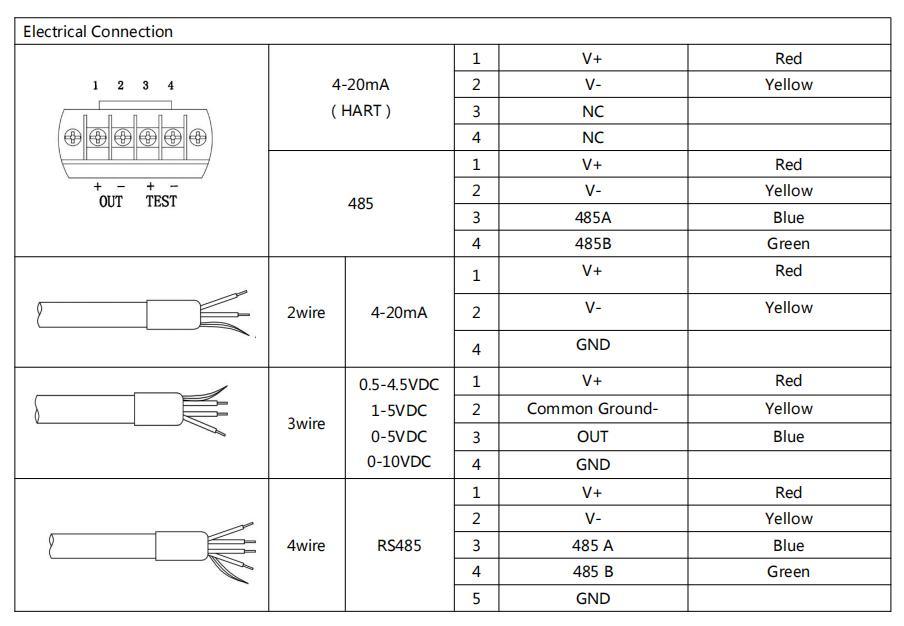

Output Signal | Supply Voltage | Output Type |

| 4~20mA | 12~30VDC | 2/3/4 wire |

| 0~10/20mA |

3 wire |

| 0/1~5V |

| 0/1~10V |

| 0.5~4.5V | 5VDC |

| RS485 Communication Protocol |

Installation tips:

1. The installation position should be reasonable, avoid external

interference and damage, and facilitate maintenance and cleaning.

2. The equipment should be checked and calibrated before

installation to ensure that it is working properly.

3. Overload and overpressure should be avoided during use, so as

not to damage the equipment or affect the measurement accuracy.

4. Equipment should be regularly maintained and cleaned to keep it

in good working condition.

5. Strong electromagnetic interference should be avoided during

use, so as not to affect the measurement accuracy.

6. In the process of use should pay attention to explosion-proof

measures to avoid dangerous accidents.

7. In the process of use, attention should be paid to the nature

and temperature range of the liquid, and the appropriate equipment

model and material should be selected.

8. When the equipment is damaged or faulty, it should be repaired

or replaced in time to avoid affecting production and safety

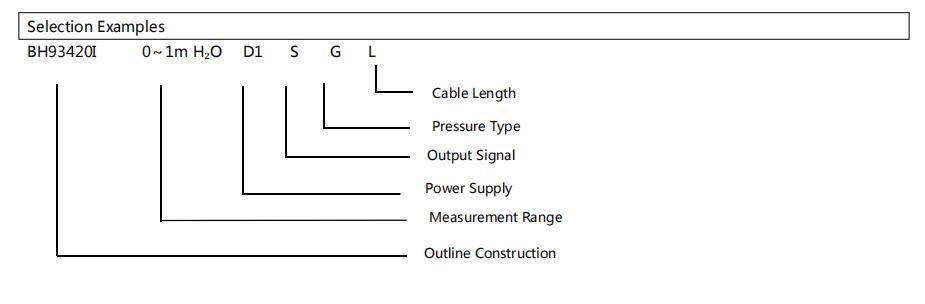

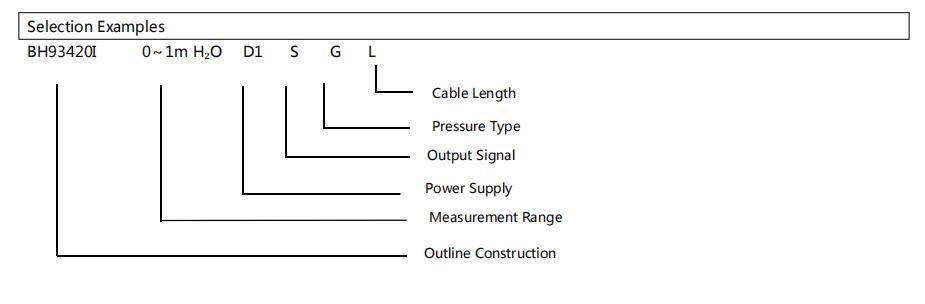

| Order Guide: |

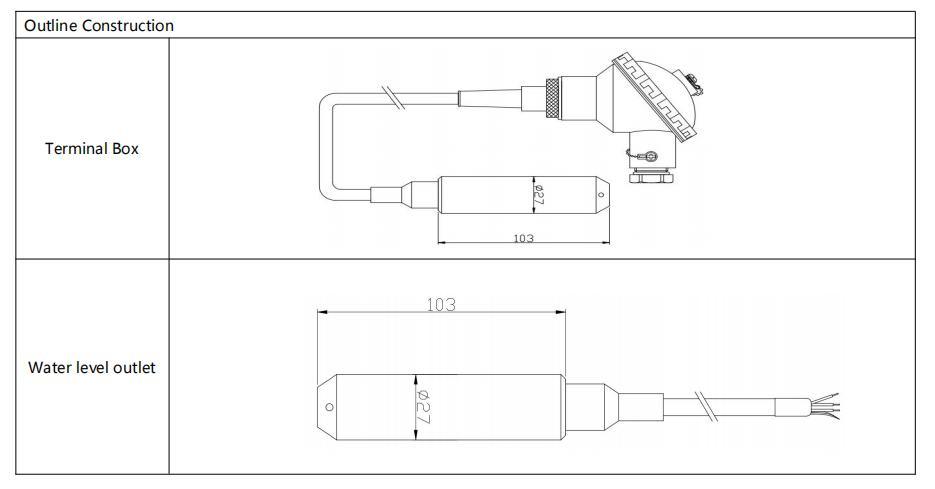

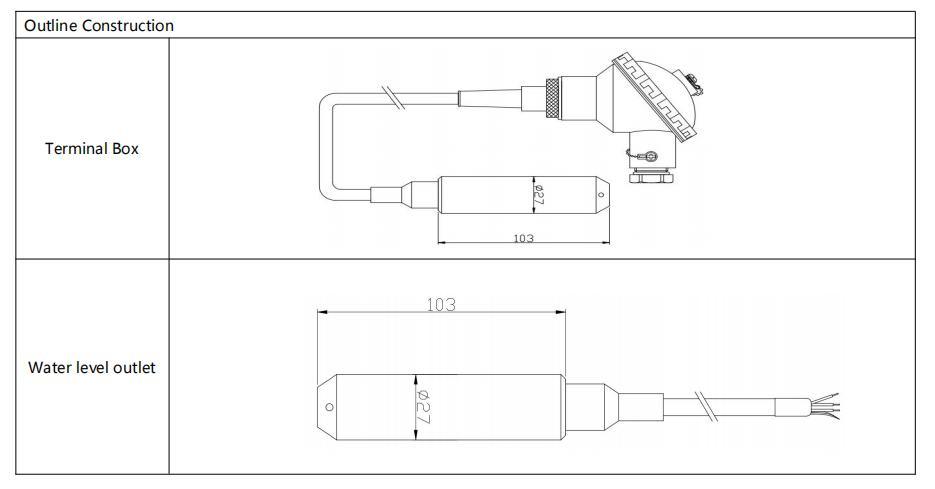

| BH93420 | Code | Outline Construction |

| I | Pressure Transmitter |

| Measurement Range | 0~10m…400m |

| Code | Power Supply |

| D1 | 24VDC |

| D2 | 5VDC |

| D3 | Other |

| Code | Output Signal |

| S1 | 4~20mADC | S5 | 0~20mADC |

| S2 | 1~5VDC | S6 | 0~10VDC |

| S3 | 0~5VDC | S7 | 0.5~4.5VDC |

| S4 | 0~10mADC | S8 | RS485 |

| Code | Pressure Type |

| G | Gauge Pressure |

| A | Absolute Pressure |

| S | Sealed Reference Pressure |

| Code | Material |

| 01 | 304 Stainless Steel |

| 02 | 316L Stainless Steel |

| Code | Cable Material |

| C1 | PE |

| C2 | PU |