| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Roof Panel Roll Forming Machine |

|---|---|

| Brand Name: | Sussman |

| Model Number: | SM-RP |

| Certification: | CE ISO SGS |

| Place of Origin: | Wuxi Jiangsu China |

| MOQ: | 1 set |

| Price: | negotiable |

| Payment Terms: | T/T L/C |

| Supply Ability: | 30 sets per months |

| Delivery Time: | 75 days after deposit |

| Packaging Details: | Standard packing |

| Type: | Trapezoidal Roof Panel Roll Forming Machine |

| Hydraulic power: | 4Kw |

| Roller statione: | About 20 stations |

| Main Motor Power: | 7.5kw |

| Way Of Drive: | 1.2 inch single chain |

| Company Info. |

| Sussman Machinery(Wuxi) Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

0.2mm-0.5mm Thickness Egypt Popular Trapezoidal Roof Tile Roll

Forming Machine with 1100mm Effective Width

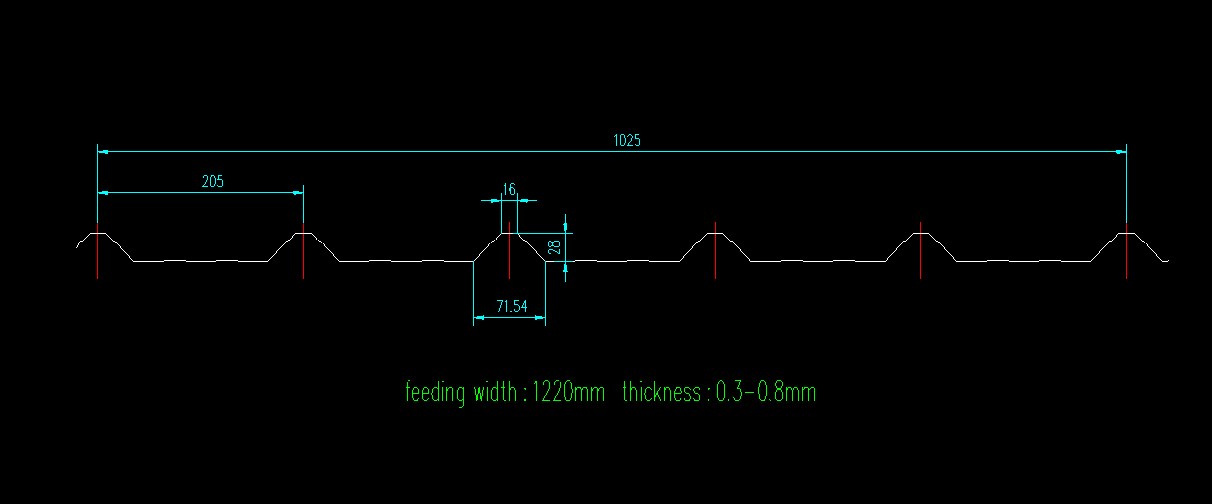

This panel is a steel panel with a trapezoidal shape, covered on

both sides by a layer of aluminum and zinc (Galvalume or Aluzinc),

which guarantees a roof resistant to environmental oxidation,

waterproof and durable. Its medium wave height allows it to be

applied as a metal roof and wall.

Technical parameter:

| Item NO | Description | Offered specification |

| 1.0 | Roll forming machine | |

| 1.1 | Rolling speed | 12-15m/min(not include cutting time) |

| 1.2 | Rolling thickness | 0.2mm-0.5mm |

| 1.3 | Raw material | Color painted coils, Aluminium, Zinc, Galvanized |

| 1.4 | Main Motor | 7.5KW |

| 1.6 | Dimension | About 8000×1600×1200(mm) |

| 1.7 | Effective width | 1100mm |

| 1.8 | Feeding Coil width | 1250mm |

| 1.9 | Roller stations | About 20 stations |

| 1.10 | Roller material | 45#forge steel, coated with chrome |

| 1.11 | Shaft diameter | Φ76mm |

| 1.12 | Transmission | By chain 1.2 inch |

| 1.13 | Material of chain | 45# forged steel with frequency quenching, 12A |

| 1.14 | Material of cutting | Cr12Mov with quench HRC58-62° |

| 1.15 | Tolerance | 10m+-1.5mm |

| 1.16 | Hydraulic station | 4kw |

Machine List:

| S.N | Name | Quantity |

| 1 | 5 ton passive decoiler | 1 set |

| 2 | Main roll forming machine | 1 set |

| 3 | Hydraulic cutting | 1 set |

| 4 | Control box | 1 set |

| 5 | Passive output table | 1 set |

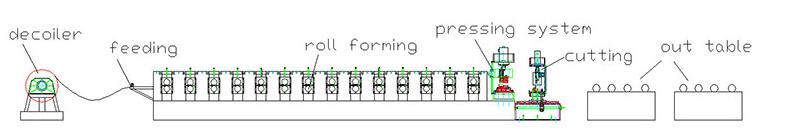

working flow

Profile Drawing

Machine Shows

Our service

1. Professional mechanical background sales for better undestanding

customer's need

2. Experienced in China machine industry for supplying

comprehensive machines and equipments

3. Strictly product manufacturing and quality controlling to ensure

every machine we sold is satisfied with our customer

4. Engineers available to service machine overseas, for example

installation, training, etc

5. Lifelong service for spares, ware parts, technical supporting,

etc

|