| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

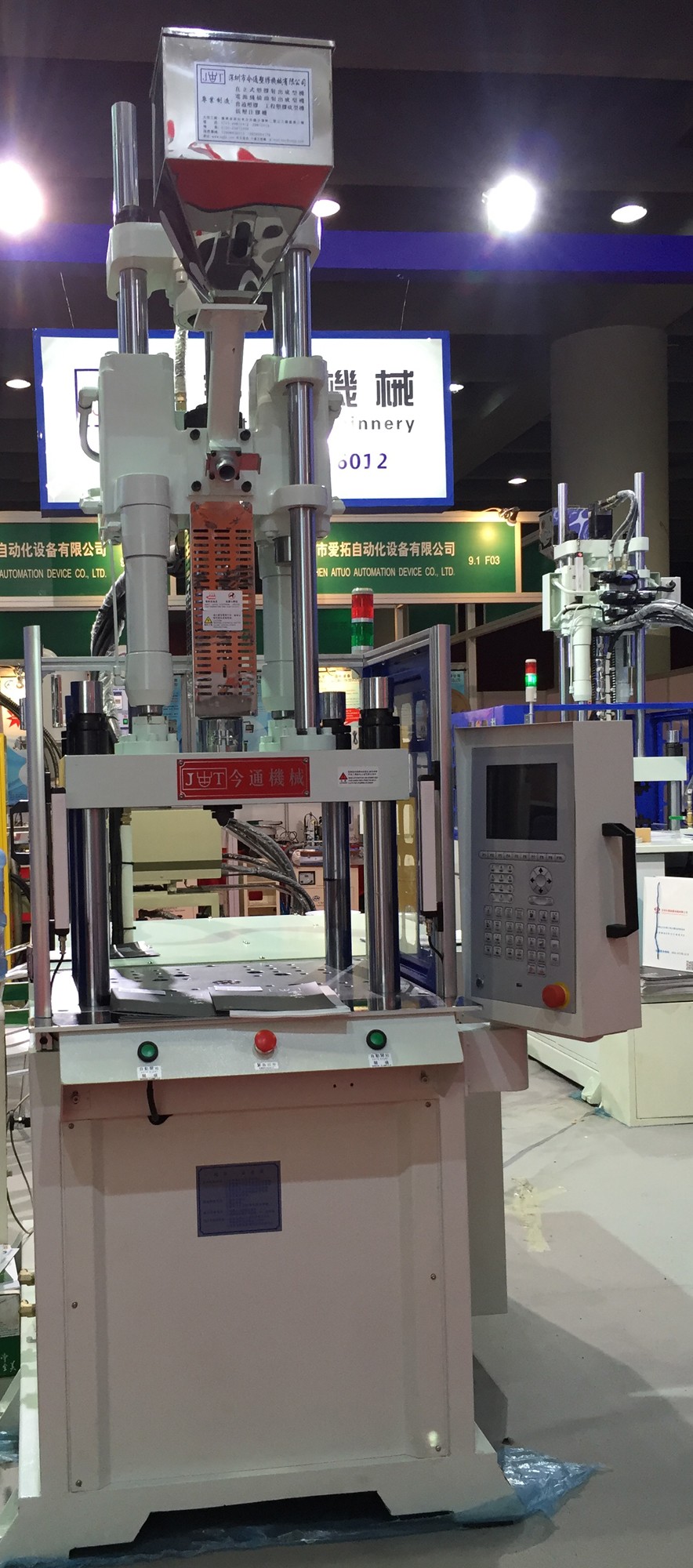

| Categories | Plastic Vertical Injection Moulding Machine |

|---|---|

| Place of Origin: | Guangdong, China |

| Model Number: | JTT-350 |

| Brand Name: | JINTONG |

| Packaging Details: | plywood for manual vertical injection molding machine for chip 35T |

| Supply Ability: | 600 Piece/Pieces per Month manual vertical injection molding machine for USB 35T |

| Price: | $8,200.00/pieces 1-4 pieces |

| Plastic Processed: | PP, PVC, PA, ABS/PP |

| Condition: | New |

| Style: | VERTICAL |

| Plasticizing Capacity(g/s): | 50 |

| Mold Height(mm): | 110 - 240 mm |

| Ejector Number: | 1 |

| Ejector Stroke(mm): | 45 mm |

| Ejector Force(kN): | 13 kN |

| Theoretical Shot Volume(cm³): | 88 cm³ |

| Injection Rate (g/s): | 50 g/s |

| Machine Type: | Hydraulic |

| Injection Weight (g): | 80 g |

| Screw Speed (rpm): | 1 - 205 rpm |

| Screw diameter (mm): | 32 mm |

| Screw L/D Ratio: | 24 |

| Distance between Tie Bars: | 340mm |

| Weight (KG): | 1400 kg |

| Type: | Other |

| Open Stroke(mm): | 350 mm |

| Power (kW): | 6.7 kW |

| Warranty: | 1 Year |

| Key Selling Points: | Automatic |

| Applicable Industries: | Manufacturing Plant |

| Showroom Location: | None |

| Machinery Test Report: | Provided |

| Video outgoing-inspection: | Provided |

| Warranty of core components: | 1 Year |

| Core Components: | Bearing, Pump, PLC, Pressure vessel |

| Opening Stroke: | 180MM |

| After-sales Service Provided: | Engineers available to service machinery overseas |

| screw diameter: | 20cm 25cm 30cm |

| screw stroke: | 100mm |

| Product name: | manual vertical injection molding machine for chip JTT-350 |

| opening force: | 6.5T |

| platen size: | 545*390mm |

| max daylight: | 340/280mm |

| min old height: | 160/100mm |

| ejector force: | 1.3T |

| Port: | SHENZHEN |

| Company Info. |

| Dongguan Jintong Plastic Machinery Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Max Daylight 340/280mm 35T Vertical Injection Molding Machine For Chip Automatic

1) vertical clamping, vertical injection,

2) clamping force, injection weight and shot speed can be changed according to actual demand.

3) 2 stations, 3 stations , multi-station(one up die, two or four down die), easy for operate insert parts, improve productivity

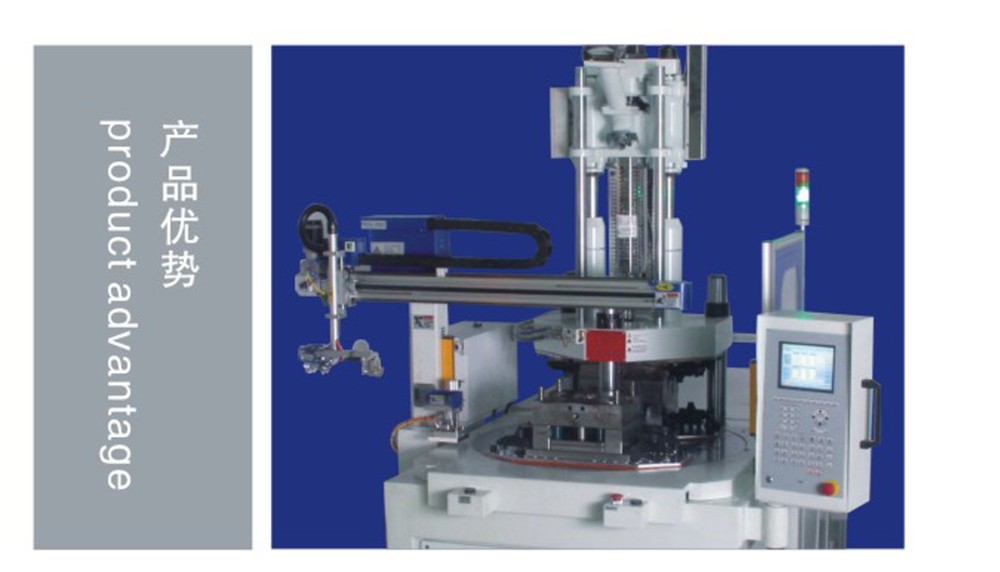

PRODUCT ADVANTAGE

Energy-saving: save 30% energy compared to similar products by

using SIFU pump system

High efficiency: SIFU motor have max speed 2200/min to increase oil

pump output and improve more than 15% productivity speed

Low heating: save 55% cooling water quantity at least compared to

similar products

Low noise: optimize motor working condition with imported bearing

and oil pump to reduce 15-20db working noise

Precision: use completely close-cycle control with pressure sensor

and motor rotary encoder to improve product consistency

SERVICE ADVANTAGE

17 years of customer service experience and summarizing customer feedback, Jintong develop a systematic and standardized service process, and also establish 24 hour response mechanism to wensure timely solve customers problems and offer perfect service to customers as soon as possible.

91.8% Response Rate

91.8% Response Rate

91.8% Response Rate

|