| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Cable Tray Roll Forming Machine |

|---|---|

| Brand Name: | LBM |

| Model Number: | LBM-CTM-007 |

| Certification: | ISO 9001: 2000 |

| Place of Origin: | Wuxi City, Jiangsu |

| MOQ: | 1 |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Delivery Time: | 30-40days |

| Price: | Negotiation |

| Supply Ability: | 25 Sets per Month |

| Packaging Details: | Export sea worthy packing with each machine fixed and protected in the container |

| Warranty:: | 18 Months |

| Electric Voltage:: | 380V 50HZ 3 Phase (or Custom) |

| PLC system: | Panasonic, Japan |

| Roller stations: | 20 rows |

| Feature: | High Stability |

| Working Speed: | 12m/min |

Later Punching Type Cable Tray Roll Forming Machine Automatic Controlled By Plc System

1. Main Technical Details

| 1 | Production | Width of the profile: 100-600mm |

| Height of the profile: 50-100mm | ||

| Thickness: 1-2mm, galvanized metal steel,steel coil,or equivalent | ||

| 02 | Un Coiler | 8 tons hydraulic |

| 03 | Punching | Hydraulic punching, 1 set |

| 04 | Forming section | Rolling Speed: 5-10 m / min |

| Roller Stations: About 20 stations | ||

| Roller Material: Gcr15with quenching | ||

| Shaft: DIA 90mm | ||

| Maim Motor Power: 15Kw | ||

| 05 | Cutting system | Hydraulic cutting Power: 7.5Kw |

| Material of Cutting: CR12 with quench treatment | ||

| Hardness: HRC58-62 | ||

| Tolerance: +-1.5mm | ||

| 06 | Electric Source | 380V, 50HZ, 3 phase Also can satisfy Customer's require |

| 07 | Electrical control system | Control System, PLC (Panasonic) as list in the note |

| 08 | Weight | About 18 tons |

| 09 | Change Size | Profile width and height adjustment, Control by the motor |

| 10 | Way Of Drive | 1.2 inch single chain |

| 11 | Size of main machine | (L*W*H): 15m*1.5m*1.8m |

2. Main Components:

| 8 ton hydraulic de-coiler | 1 set |

| Leveling | 1 set |

| Hydraulic Punching | 1 set |

| Hydraulic Pre - cutting | 1 set |

| Main roll forming machine | 1 set |

| Control box | 1 set |

| Hydraulic station | 1 set |

| Out table | 2 unit |

| Spare parts | 1 package |

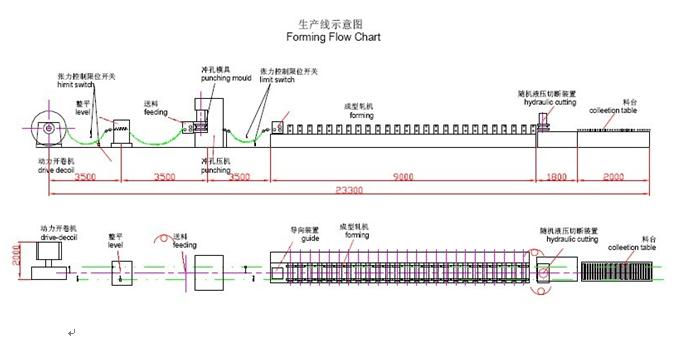

3. Work Flowchart:

4. Our Advantage

- This EU type of light gauge steel roll forming machine line include 3 tons of manual decoiler, roll forming host, PLC control system, hydraulic cutting system and output table

- The manual decoiler is free for each machine, it can hold 3 tons of strips, and normally the space between manual decoiler and the machine is 3 meters.

- Feeding table has 1 row of roller to make the strip flat, and the roll forming host can produce the light keels as per customer's request.

5. Our service

(processes)

First step:

Designing. After order confirmation, we start to design the machine, such as the basement, structure, rollers, shafts, power, cutting device, programs and so on.

Second step:

The main parts, like rollers and shafts are produced by ourselves. We have several high-precision CNC lathe and other kinds of new machine tools, so that the quality and precision can be controlled.

Third step:

Assembling. The machines are assembled by technicians with years of experience, which can help workers improve the production efficiency and machine’s quality.

Fourth step:

Test. Raw material of different specifications are prepared for testing. And during test, long enough material is used. Because if the material is not long enough, some defects can not be exposed.

Five step:

Delivery. Because of the weight of machine itself, the packing is usually bare packing. Machine will be fixed inside container by steel wire, in order to make sure it won’t move during transportation and avoid any kinds of damage of machine and container.

6. Picture

|