| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | High Pressure Filter Press |

|---|---|

| Brand Name: | DUBHE |

| Model Number: | DHP-1000 |

| Place of Origin: | CHINA |

| MOQ: | 1Set |

| Payment Terms: | L/C, T/T, Western Union |

| Product Name: | High-pressure Belt Filter Press |

| Belt Width (mm): | 1000 |

| Treating Capacity (m3 /hr): | 5.0~18 |

| Dried Sludge D.S(kg/hr):: | 76~240 |

| Water Content Rate (%): | 55~70 |

| Power Consumption (HP): | 3 |

| Application: | Industrial Solid Liquid Separation Processes |

| Main Drive: | Adopting an internationally brand NORD |

| Company Info. |

| SHANGHAI DUBHE ENVIRONMENTAL PROTECTION&TECHNOLOGY CO.,LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

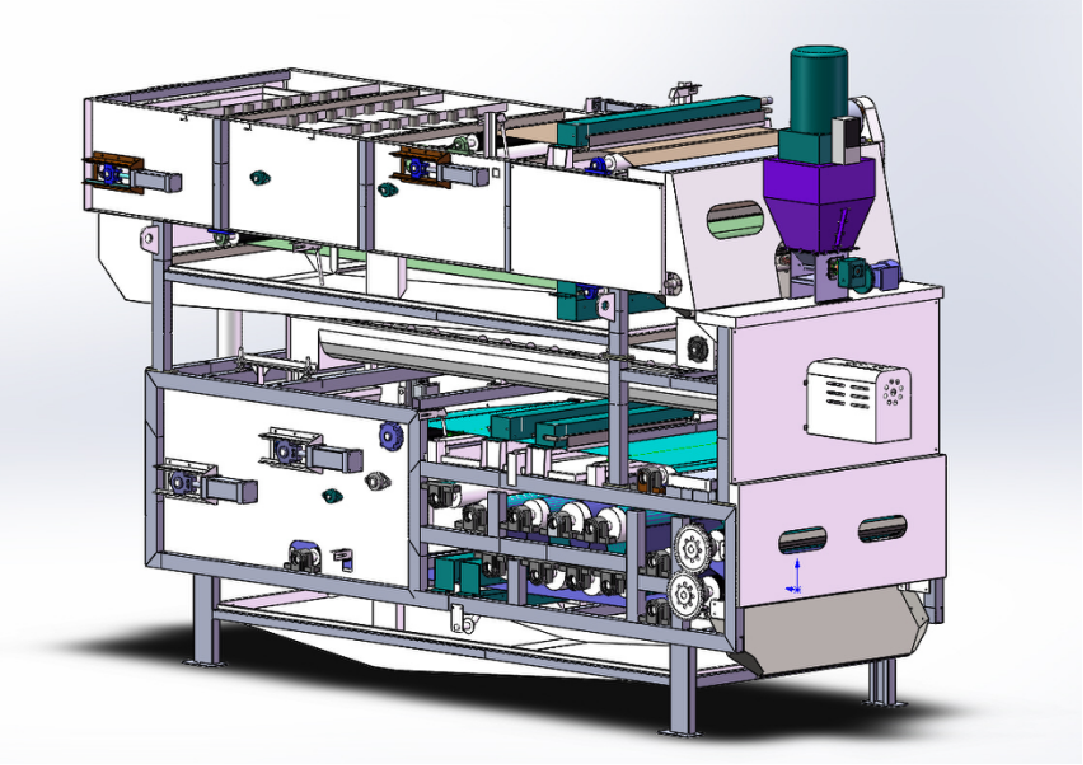

High Pressure Deep Dehydrator for Industrial Solid Liquid Separation Processes DHP-1000

Description:

Description:The DHP is an advanced and efficient high-pressure deep dehydrator designed for industrial solid-liquid separation processes. It is specifically engineered to remove moisture from various types of sludge and achieve a high level of dehydration.

With its robust construction and powerful hydraulic system, the DHP ensures effective dewatering of the sludge, resulting in a significant reduction in moisture content. This not only facilitates the disposal and treatment of the sludge but also minimizes the volume for transportation and storage.

The DHP utilizes a high-pressure mechanism to exert strong pressure on the sludge, effectively compressing it and forcing out the water content. This process is highly efficient and ensures thorough separation of the liquid and solid components.

Features:

Features:

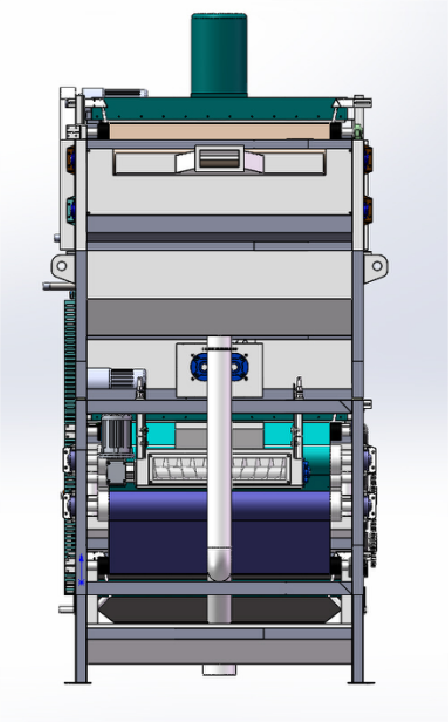

1. Abnormal Deviation Correction Device

Automatic continuous detection; Correct filter cloth deviation; Ensure the machine's regular operation and increase the filter cloth's service life.

2. Sludge Distributor

Spread the concentrated sludge evenly on the upper filter cloth to ensure that the sludge is pressed evenly, improve the dehydration rate and extend the service life of the filter cloth.

3. Cylinder Three-point Combination Tensioning Device

Tensioning the filter cloth through cylinder tension to ensure stable, leak-free, and high-safety operation within a certain range.

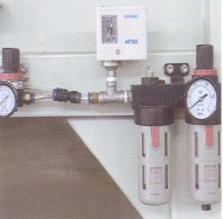

4. Pneumatic Triple

Composed of Air Filter, Pressure Reducing Valve, and Oil Mist Collector, it can effectively filter water in the air, lubricate pneumatic components, and extend the service life of pneumatic components.

5. Pressing Roller

Made of SUS304, TIG reinforced welding, and after finishing, the structure is fastened without breaking.

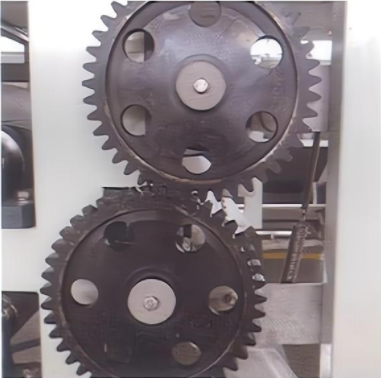

6. Synchronous Wheel

The driving roller of the pressing section adopts the synchronous gear design, which is reliable in operation, low in failure rate, easy to maintain, and improves the stability of operation.

7. Waterproof Ring

Installed on the inner side of the bearing, it can prevent the dehydrator from splashing water from the inner side to the inside of the bearing during operation and extend the service life of the bearing.

8. Box Bearing

This bearing is suitable for high-pressure working conditions and adopts a fully enclosed structure, which can prevent the entry of dust and mud, extend the service life of the bearing, and make it easy to replace the bearing at a later stage.

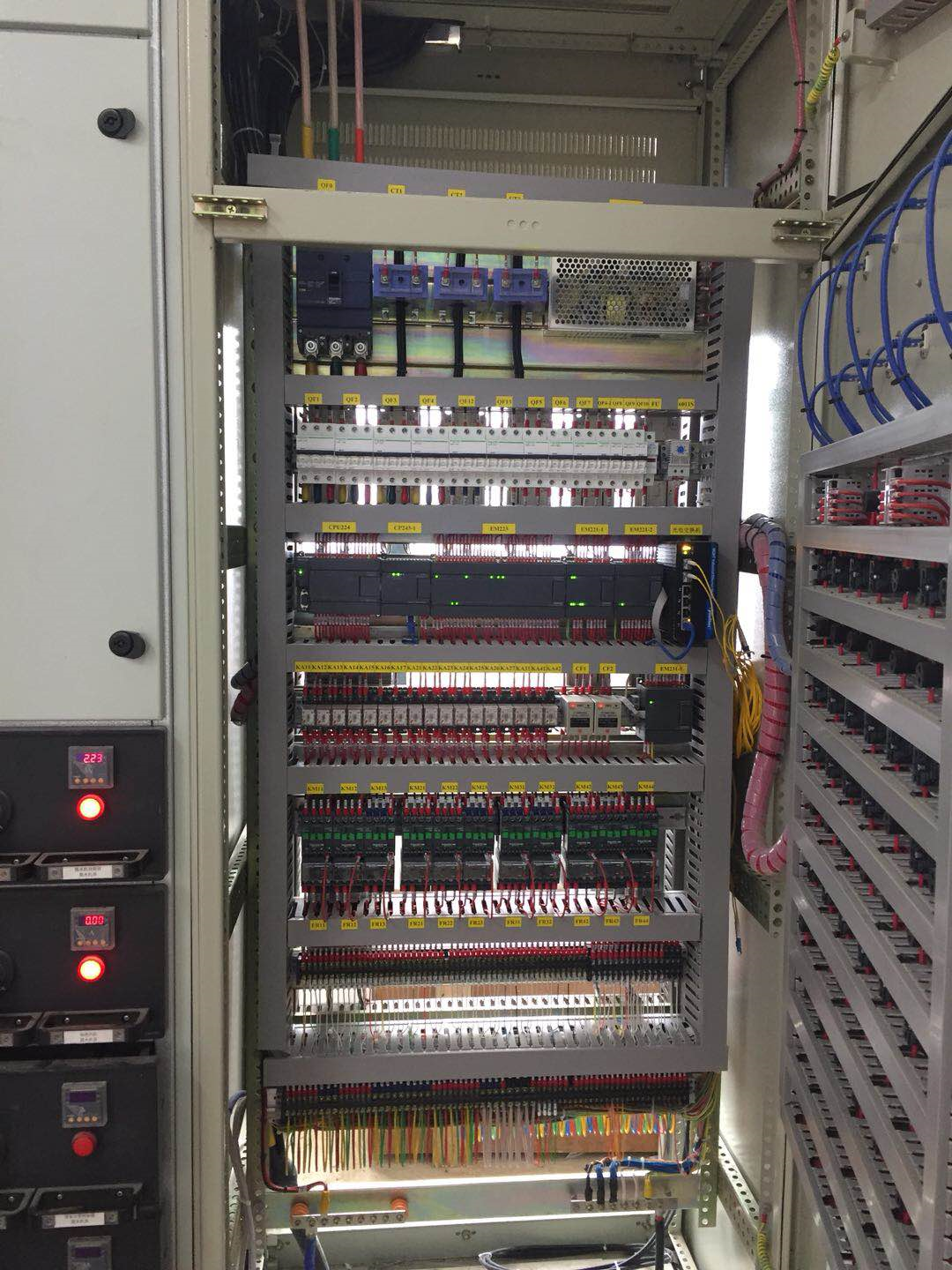

9. Multifunctional Electric Cabinet

Electrical components adopt internationally renowned brands such as Omron Schneider. The PLC adopts Siemens, and the frequency converter adopts Danfoss and ABB from Germany, with stable performance and easy operation. It is equipped with a leakage protection device to ensure safe operation.

10. Precision Feeder

Mainly composed of two parts: arch breaking and conveying. The arch-breaking device can effectively prevent the bridging of the conditioner, and the required amount of medicine can be accurately dosed by screw conveying.

11. Main Drive

Adopting an internationally renowned brand NORD reducer to ensure stable operation, long service life, and low maintenance costs. In addition, SEW brand reducers can be selected according to the situation.

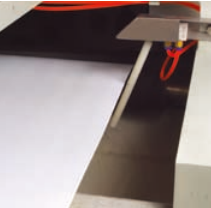

12. Filter Cloth

Using domestic high-quality filter cloth or imported from Germany, the filter cloth is excellent in water filtration, durability, and corrosion resistance, and is not easy to deform, effectively reducing the moisture content of mud cake.

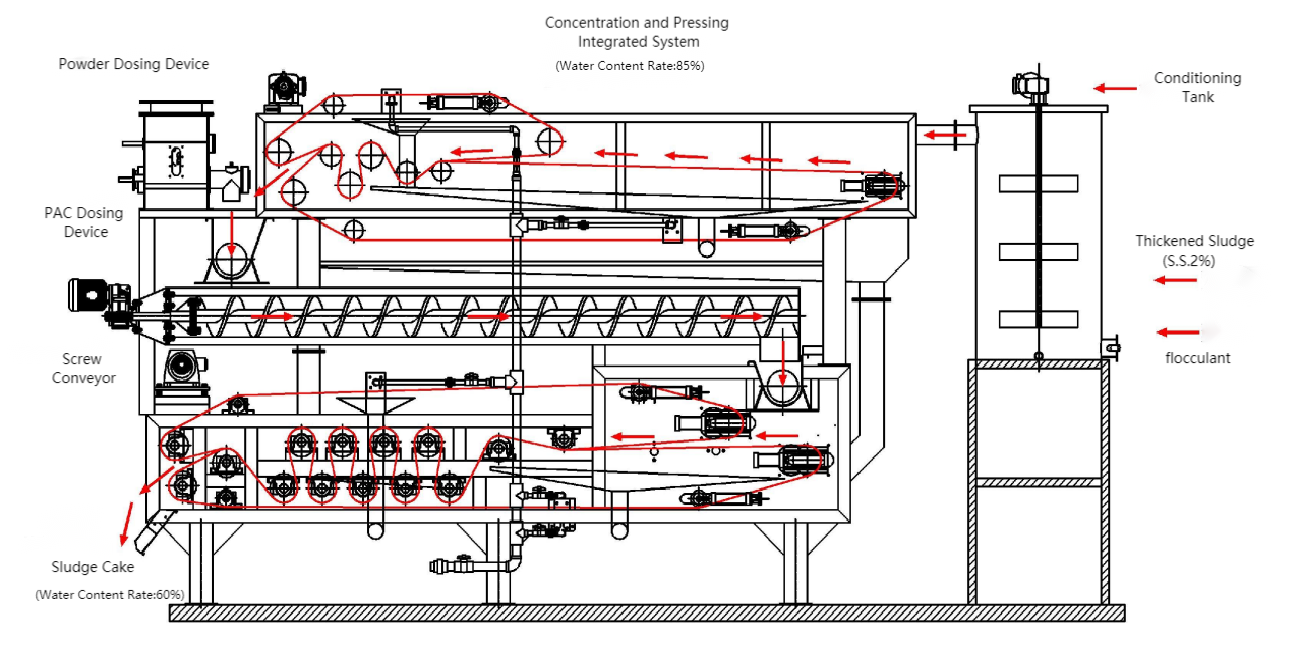

Process:

Process:1. Introduce thickening tank sludge into the conditioning tank to improve sludge properties;

2. The pretreated sludge then enters the thickening section;

3. The moisture content of the sludge is reduced to about 85%;

4. Add an appropriate amount of sludge conditioner, mix evenly, and dehydrate under high pressure;

5. Further reduce the moisture content of sludge to 60% or below.

How Our Belt Filter Press Works:

How Our Belt Filter Press Works:

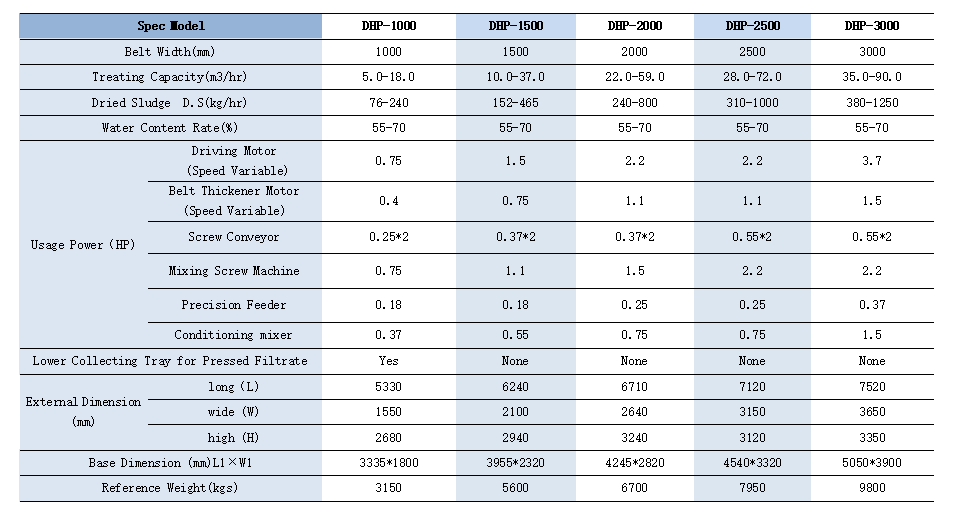

Technical Data & External Dimensions of Belt Filter Press:

Technical Data & External Dimensions of Belt Filter Press:

Welcome to DUBHE:

Welcome to DUBHE:

Q1: How to pay?

A:100%T/T, Paypal, West Union, MoneyGram, Secure payment and Trade Assurance.

Q2: What's the delivery time?

A: 30-60 days.

Q3: What's the MOQ?

A:1set.

Q4: Do you have an inspection report for the material?

A: We can provide the certificate.

|