| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Encapsulated Control Line |

|---|---|

| Brand Name: | Meilong Tube |

| Model Number: | 1 / 4 '' OD x 0.049 '' WT |

| Certification: | ISO9001 : 2015 |

| Place of Origin: | China |

| MOQ: | 1000 meters |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100 metric tons per month (including duplex steel tubing, nickel alloy tubing) |

| Delivery Time: | 7 days |

| Packaging Details: | Level wound coiled on spools/drums, and packed in wooden cases |

| Alloy: | TP316L, UNS S31603 |

| Surface: | Clean and bright |

| Condition: | Annealed |

| Properties: | Enhanced tensile and yield |

| Feature: | High pressure tubing |

| Application: | Down hole hydraulic control in oil and gas wells |

| Standard: | ASTM A269 |

| Size: | Tight dimensional tolerances |

| Application Standard: | NACE MR0175 / ISO15156 |

| Test: | 100% length is hydraulic tested |

| Company Info. |

| Suzhou Meilong Tube Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

PVDF Encapsulated Control Line Flatpack with Two Tubes for Downhole Application in Oil Wells

Meilong Tube offers the encapsulation of control lines to provide increased durability, as well as chemical and corrosion resistance to meet each project’s specialized requirements, we offer different encapsulation types, such as: HDPE (High Density Polyethylene), Santoprene, PVC (Polyvinyl Chloride), Haylar and PVDF (Polyvinylidene Fluoride).

Welded hydraulic control line is floating plug drawn to ASTM specifications and is available in any length. Material types for hydraulic control lines include stainless steel TP316L which is suitable for sweet to moderately corrosive environments, Duplex stainless steel 2205, Super Duplex stainless steel 2507, nickel alloy Incoloy 825 and Inconel 625 are suitable for severely corrosive environments and high working pressures and temperatures. Control system fluids must be compatible with the environments and operating temperatures of the control line.

Control line encapsulation also is available, where requested, to provide additional crush and abrasion resistance during installation. The encapsulation material should be matched for compatibility with well fluids and temperature requirements.

Encapsulated Control Line Flatpack

Encapsulation is a plastic that is extruded over metal tube. Encapsulation prevents damage to the metal tubes during the manufacturing process. The encapsulation also provides additional abrasion resistance and is required if cable protectors are installed to enhance the holding force over each production tubing connection.

Encapsulations are available in a wide range of configurations with options of single pass encapsulation and dual pass encapsulation for added protection.

Application of Flatpack

Flatpacks are commonly used when several different lines are terminated at approximately the same depth in the well.

Common applications include intelligent well systems, deep-set chemical injection lines with downhole gauge cable and safety valve lines with shallow set chemical injection lines. For some applications bumper bars are also encapsulated into the flatpack to provide additional crush resistance.

Standard & Approvals

Control Lines are manufactured according to applicable ASTM standards for each specific material.

Tubes can be supplied flushed, filled, and filtered per client requirements and to the appropriate NAS/SAE standards.

Quality & Testing

- Manufactured in accordance with Standard Inspection and Quality Plans

Design & Construction

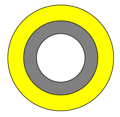

- Encapsulation for single line

- Encapsulation profiles to suit customer application

- Custom Line Marking

- Full range of application materials

Encapsulation Materials

| Polypropylene | -25C to 150C | Good resistance to brines |

| Santoprene | -30C to 150C | Good resistance to brines |

| Nylon 11 | -60C to 135C | Good resistance to hydrocarbons, good abrasion resistance |

| PVDF | -30C to 150C | Good resistance to brines and hydrocarbons, good abrasion resistance |

| FEP | -110C to 200C | Good resistance to brines and hydrocarbons |

Features of Encapsulated Control Line Flatpack

Maximize protection of downhole line

Increase crush resistance during installation

Protect control line against abrasion and pinching

Eliminate long term stress corrosion failure of control line

Improve clamping profile

Single or multiple encapsulation for ease of running and added protection

Available Alloy Grades for Control Line Tubing Inside Encapsulation

| Alloy Tubing | Hydraulic Control | Chemical Injection | Chloride Pitting / Crevice Corrosion Resistance | H2S / CO2 Resistance | Chloride Stress Corrosion Cracking (SCC) Resistance | UNS / ASTM Specification |

Stainless 316L – 170 MPa min. yield strength Seam-Welded Pressure Tubing | • | • | S31603 / A269 | |||

Duplex 2205 – 485 MPa min. yield strength Seam-Welded Pressure Tubing | • | • | • | • | • | S32205 / A789 |

Duplex 2507 – 550 MPa min. yield strength Seam-Welded Pressure Tubing | • | • | • | • | • | S32750 / A789 |

Incoloy 825 – 240 MPa min. yield strength Seam-Welded Pressure Tubing | • | • | • | • | • | N08825 / B704 |

Inconel 625 – 414 MPa min. yield strength Seam-Welded Pressure Tubing | • | • | • | • | • | N06625 / B704 |

Chemical Composition of TP316L

| Carbon | Manganese | Phosphorus | Sulfur | Silicon | Nickel | Chromium | Molybdenum |

| % | % | % | % | % | % | % | % |

| max. | max. | max. | max. | max. | |||

| 0.035 | 2.00 | 0.045 | 0.030 | 1.00 | 10.0-15.0 | 16.0-18.0 | 2.00-3.00 |

Norm Equivalence

| Grade | UNS No | Euro norm | Japanese | |

| No | Name | JIS | ||

| Alloy | ASTM/ASME | EN10216-5 | EN10216-5 | JIS G3463 |

| 316L | S31603 | 1.4404, 1.4435 | X2CrNiMo17-12-2 | SUS316LTB |

TP316L is an austenitic chromium-nickel stainless steel with molybdenum and a low carbon content.

Corrosion Resistance

Organic acids at high concentrations and moderate temperatures

Inorganic acids, e.g. phosphoric and sulphuric acids, at moderate concentrations and temperatures. The steel can also be used in sulphuric acid of concentrations above 90% at low temperature.

Salt solutions, e.g. sulphates, sulphides and sulphites

Caustic environments

Austenitic steels are susceptible to stress corrosion cracking. This may occur at temperatures above about 60°C (140°F) if the steel is subjected to tensile stresses and at the same time comes into contact with certain solutions, particularly those containing chlorides. Such service conditions should therefore be avoided. Conditions when plants are shut down must also be considered, as the condensates which are then formed can develop conditions that lead to both stress corrosion cracking and pitting.

TP316L has a low carbon content and therefore better resistance to intergranular corrosion than steels of type TP316.

Standard Flatpack Encapsulation Profiles

| Round, Single Line | Item | Standard Dimensions |

| 1/8’’ OD Line | 0.250’’ (6.35 mm) Dia. |

| 1/4’’ OD Line | 0.433’’ (11.0 mm) Dia. | |

| 3/8’’ OD Line | 0.535’’ (13.6 mm) Dia. | |

| 1/2’’ OD Line | 0.660’’ (16.8 mm) Dia. |

| Square, Single Line | Item | Standard Dimensions |

| 1/8’’ OD Line | 0.250’’ x 0.250’’ (6.35 mm x 6.35 mm) |

| 1/4’’ OD Line | 0.433’’ x 0.433’’ (11.0 mm x 11.0 mm) | |

| 3/8’’ OD Line | 0.535’’ x 0.535’’ (13.6 mm x 13.6 mm) | |

| 1/2’’ OD Line | 0.660’’ x 0.660’’ (16.8 mm x 16.8 mm) |

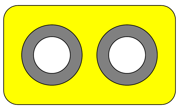

| Rectangular, 2 Lines | Item | Standard Dimensions |

| 1/4’’ OD Line | Width: 0.710’’ (18.0 mm) Height: 0.410’’ (10.4 mm) |

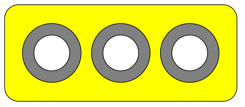

| Rectangular, 3 Lines | Item | Standard Dimensions |

| 1/4’’ OD Line | Width: 0.990’’ (25.1 mm) Height: 0.410’’ (10.4 mm) |

Properties of Hydraulic Control Line Tubing in Flatpack

Seam-welded & floating internal plug redrawn tubing. Supplied in the annealed condition

Continuous length without orbital joint welds

| Alloy | UNS | O.D. | W.T. | Working Pressure | Burst Pressure | Collapse Pressure | Test Pressure | |

| inch | inch | inch | psi | psi | psi | psi | ||

| Stainless 316L | S31603 | 1/8 | 0.125 | 0.028 | 9,931 | 40,922 | 9,525 | 11,600 |

| Stainless 316L | S31603 | 1/8 | 0.125 | 0.035 | 12,640 | 52,042 | 11,056 | 15,225 |

| Stainless 316L | S31603 | 1/4 | 0.250 | 0.035 | 5,939 | 24,474 | 6,621 | 7,250 |

| Stainless 316L | S31603 | 1/4 | 0.250 | 0.049 | 8,572 | 35,322 | 8,632 | 10,150 |

| Stainless 316L | S31603 | 1/4 | 0.250 | 0.065 | 11,694 | 48,166 | 10,562 | 13,775 |

| Stainless 316L | S31603 | 3/8 | 0.375 | 0.035 | 3,818 | 15,731 | 4,659 | 4,350 |

| Stainless 316L | S31603 | 3/8 | 0.375 | 0.049 | 5,483 | 22,575 | 6,222 | 6,525 |

| Stainless 316L | S31603 | 3/8 | 0.375 | 0.065 | 7,517 | 30,951 | 7,865 | 8,700 |

| Stainless 316L | S31603 | 3/8 | 0.375 | 0.083 | 9,808 | 40,372 | 9,551 | 11,600 |

| Stainless 316L | S31603 | 1/2 | 0.500 | 0.049 | 4,003 | 16,480 | 4,835 | 5,075 |

| Stainless 316L | S31603 | 1/2 | 0.500 | 0.065 | 5,461 | 22,512 | 6,206 | 6,525 |

| Stainless 316L | S31603 | 1/2 | 0.500 | 0.083 | 7,133 | 29,364 | 7,648 | 8,700 |

| Stainless 316L | S31603 | 5/8 | 0.625 | 0.049 | 3,144 | 12,955 | 3,957 | 3,625 |

| Stainless 316L | S31603 | 5/8 | 0.625 | 0.065 | 4,285 | 17,630 | 5,105 | 5,075 |

| Stainless 316L | S31603 | 5/8 | 0.625 | 0.083 | 5,472 | 22,513 | 6,519 | 6,525 |

| Stainless 316L | S31603 | 3/4 | 0.750 | 0.049 | 2,619 | 10,791 | 3,296 | 2,900 |

| Stainless 316L | S31603 | 3/4 | 0.750 | 0.065 | 3,570 | 14,686 | 4,283 | 4,350 |

| Stainless 316L | S31603 | 3/4 | 0.750 | 0.083 | 4,558 | 18,753 | 5,431 | 5,800 |

Theoretical burst pressure based on minimum wall thickness, and minimum tensile strength

Theoretical collapse pressure based on minimum wall thickness, and minimum yield strength

Pressure rating at 100°F (38°C), neutral and static conditions

|