| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | In Molding Roller |

|---|---|

| Brand Name: | HXSIMR |

| Model Number: | IMD-168 |

| Certification: | ISO9001/ISO14001/ISO16949 |

| Place of Origin: | SHENZHEN,CHINA |

| MOQ: | 10 pcs |

| Price: | $2.0/pcs |

| Payment Terms: | T/T, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 30000 Pieces per Day |

| Delivery Time: | 7-20 work days |

| Packaging Details: | standard packing (43cm*33cm*36cm, 10KG) |

| Material: | ABS |

| Application: | Protect |

| Shaping mode: | Plastic Injection Mould |

| Logo: | customizable |

| Surface finish: | Surface sanding |

| Process: | Injection |

| Feature: | High Quality and Cheap,High precision |

| Advantage: | All in one solution |

IMR (Imaging Manufacturing by Return Light) process for flat panel computer cases: Creating colorful computer cases

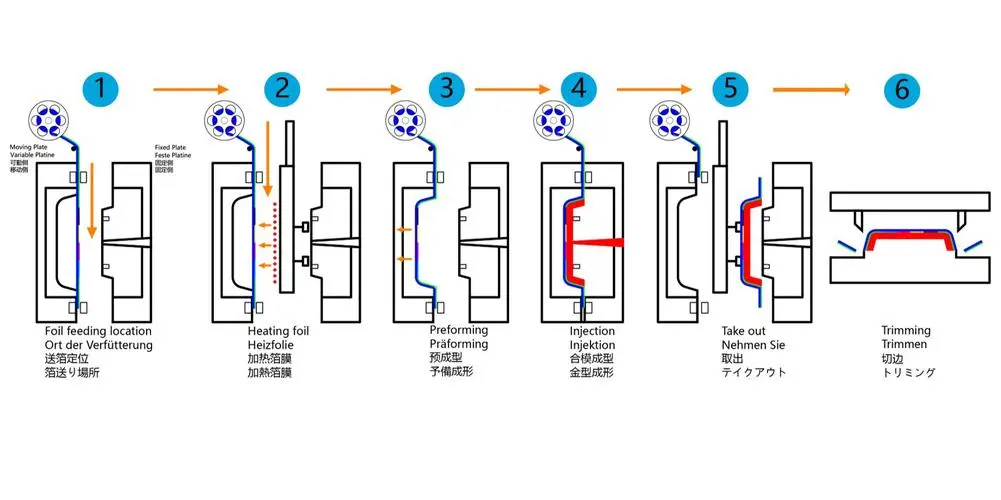

IMR process flow:

The IMR (Imaging Manufacturing by Return Light) process for flat panel computer cases is a manufacturing process that uses optical molds to create a variety of colors through the reflection of patterns on a thin film of foil. The process involves printing patterns on a thin film of foil, which are then applied to a mold used in injection-molding to create a desired color pattern on the case.

The specific process steps are as follows:

Through this process, up to 256 different colors can be created, making flat panel computer cases color options very rich. At the same time, surface treatment can enhance its wear resistance, scratch resistance, and anti-fingerprint properties, while high gloss can improve the look and feel of the case. High precision and environmental friendliness are two features of IMR process that can enhance the look and feel of the computer case and its performance.

IMR In Molding Roller Plastic process introduction:

IMR process (In Molding Roller): A transfer film formed by coating a release layer, protective layer, graphic layer, and adhesive layer on the surface of PET film as a carrier. The transfer film is fed into the mold cavity of the injection molding machine through a film feeder. Under the combined action of heat and pressure during the molding process of the hot melt plastic material in the injection molding machine, the protective layer, along with the graphic and text layers, and the adhesive layer, detach from the PET carrier film and transfer to the surface of the plastic product, enabling the plastic product to receive decoration and protection during the molding process. This is an energy-saving, environmentally friendly, labor and material saving process.

Why choose us

We are the first professional IMD PARTS manufacturer in China,Founded in 2009, the company's industrial park covers an area of more than 30000 square meters, has a high-precision dust-free workshop, and has nearly 100 excellent management personnel, 35 engineering and technical personnel, 50 quality personnel, a total of nearly 500 employees, more than 500 injection molding equipment, and a monthly production capacity of nearly 15 million pieces; From engineering research and development to mold production, diaphragm printing, diaphragm molding, diaphragm injection molding, inspection and packaging, there is a complete process production process.

Full-process dust-free workshop operation

Full-process dust-free workshop operation

Our company has won the honors of high-growth enterprise, industry benchmark enterprise, contract-abiding and creditworthy enterprise, high-tech enterprise, etc

HXS has become a long-term partner of more than ten top 100 enterprises in the world

|