| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Grain Drying Machine |

|---|---|

| Brand Name: | ChenYu Technology |

| Model Number: | 5H-12 |

| Certification: | ISO9001, ISO14001, CE |

| Place of Origin: | LU'AN,CHINA |

| MOQ: | 1 Set |

| Price: | 16500-19500 |

| Supply Ability: | 100 Sets |

| Delivery Time: | 30days after receive the payment |

| Packaging Details: | Wooden case |

| Type: | Grain drying equipment |

| Use: | Grain Drying |

| Loading capacity: | 2700-12000 KG |

| Net weight: | 2800 KG |

| Diemension (L×W×H)mm: | 4314×2979×9030 |

| Voltage: | 220V/380V |

| Power: | 7.87 KW |

| Loading time: | 50-65 Mins |

| Applicable Industries: | Food & Beverage Factory, Farms, Food Shop, Food & Beverage Shops |

| Unloading time: | 50-65 Mins |

| Drying Rate %/H: | 0.5-1.2% |

| After-sales Service Provided: | Engineers available to service machinery overseas |

| Warranty: | 18 Months |

| Company Info. |

| ANHUI CHENYU MECHNICAL CO.LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

12T/Batch Auger Grain Dryer Lateral Flow Feed Type with Husk Burner Heat Supply System

Production Information:

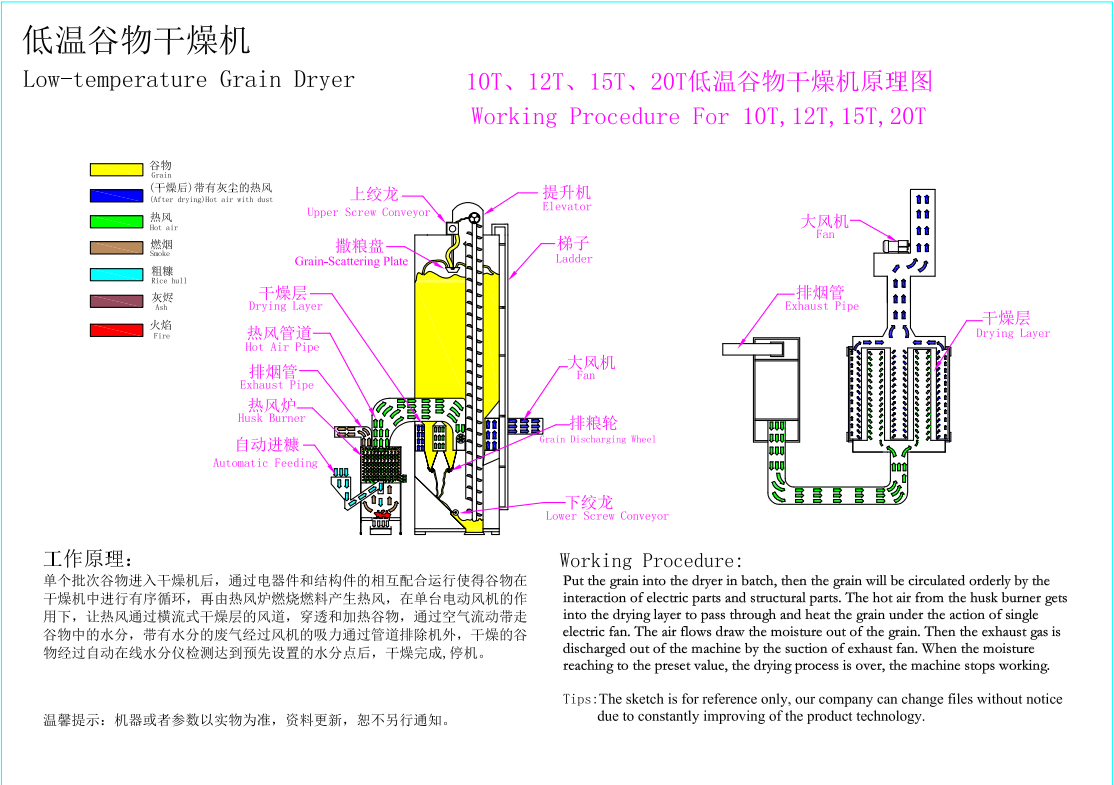

1, Using horizontal multi-slot dryer section, grain crisscrossed

loop cycle, hot exchange and evaporative way of drying to make sure

the drying is evenly and fully;

2, Prevent drying crack broken rice we adopt constant drying speed

control, drying rate and air temperature controlled by computer,

without manual settings;

3, Prevent grain spoiled, machine running under proper temperature

;

4, Prevent excessive drying adopting automatic, accurate and safe

water monitoring devices, it can be shut down automatic;

5, Body of tower is low and compact, easy to be installed;

6, High moisture rice and wheat quality also can be dried, widely

used for rice, wheat, corn, soybeans and other crops;

7, Safe, reliable, easy to be cleaned;

8, A variety of fuels available, economic, environmentally

friendly;

9, Easy to maintain, convenient to use;

10, Excellent quality raw materials for drying tower body, more

durable.

Parameters:

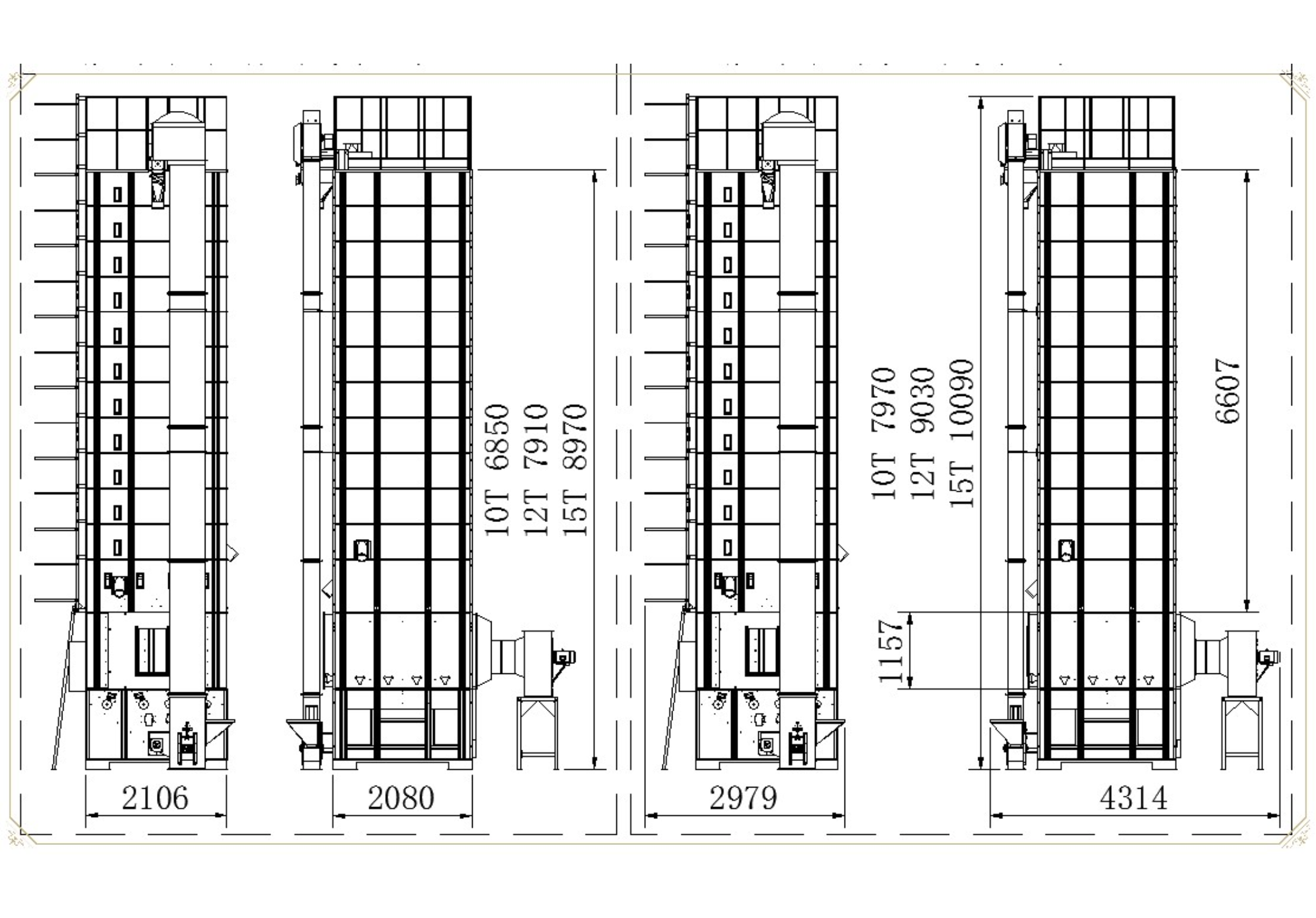

| Model (Cross type ) | 5H-12 (12T/batch) | ||

| Structure | Batch type circulating | ||

| Drying way | Indirect heating | ||

| Cyclic batch | 12 | ||

Loading capacity | paddy(kg) | 2300-12000 | |

| wheat(kg) | 2700-12000 | ||

| Total weight(kg) | 2800 | ||

| Diemension Body (L×W×H)mm | 2106×2080×7910 | ||

| Diemension (L×W×H)mm | 4314×2979×9030 | ||

Ventilation fan | Model | 4-72-6A | |

| rated air flow(m3/h) | 6677-13353 | ||

| Burner ( Optional) | Model | husk burner/gas burner/Diesel burner | |

| Ignition | manual | ||

| electricity | Voltage/frequence | three phase 380V single phase 220V/50hz | |

| kW motor power | 7.87 | ||

| function | loading time | paddy(min) | 55-65 |

| wheat(min) | 50-60 | ||

unloading time | paddy(min) | 55-65 | |

| wheat(min) | 50-60 | ||

| drying rate (%/h) | 0.5-1.2% | ||

| device | safety device | Full load buzzer,Thermal-over relay,Temperature Control Instrument, Hot air temperature sensor, Overload protection device, Leakage protection device | |

| standard device | Online moisture monitor, Conveying system, Unloading system, Drying system, Tempering system, Elevator, Exhaust fan in low noise, Automatic control system | ||

Our Dryer dimension and operation process

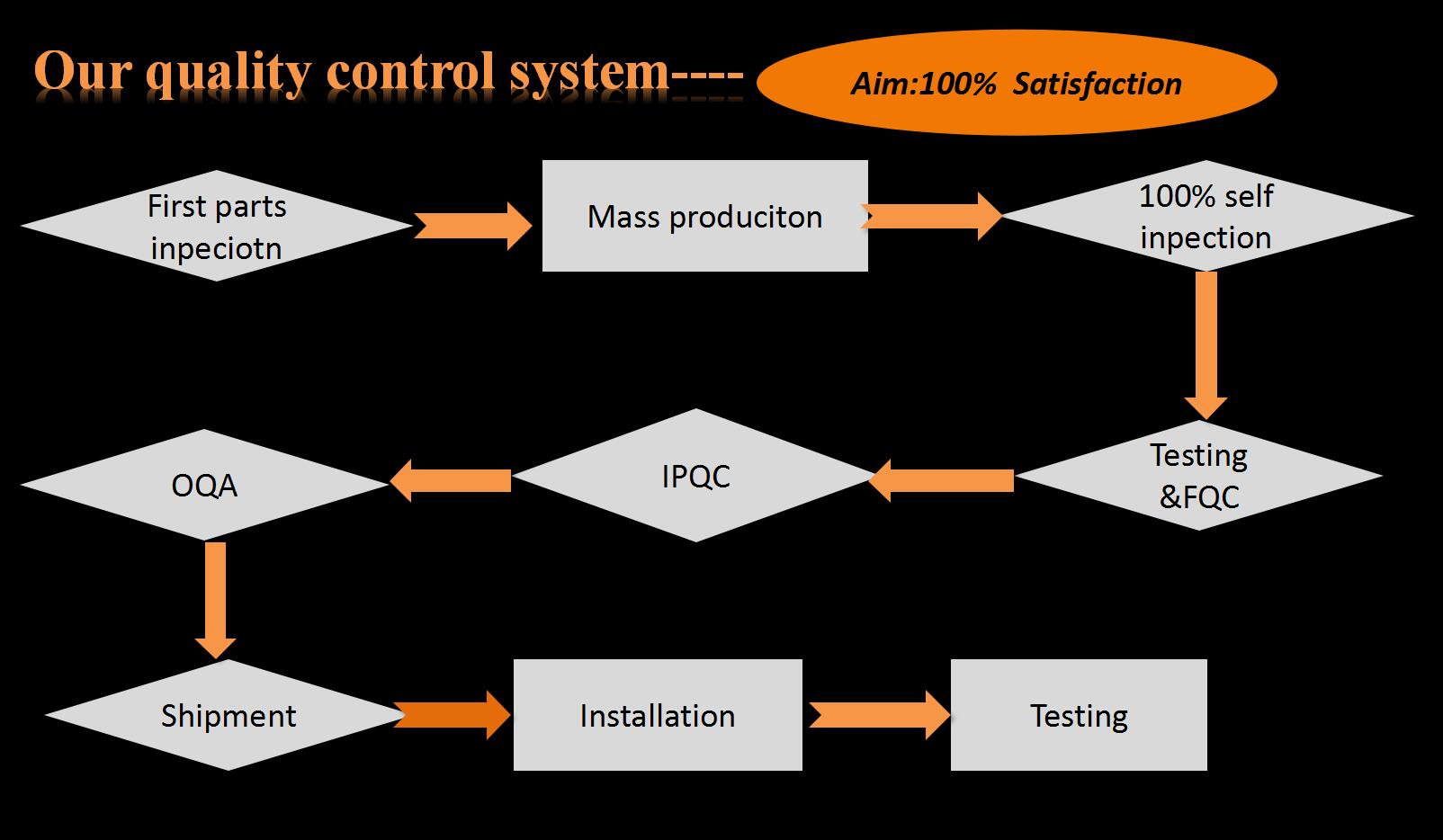

Our Quality control and produciton line

Our customer case

|