| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Multilayer PCB Assembly |

|---|---|

| Brand Name: | HNL-PCBA |

| Model Number: | PCB Assembly 010 |

| Certification: | ISO9001,IS16949, ISO14001,ROHS ,IPC-A , UL, QC080000 |

| Place of Origin: | CHINA |

| MOQ: | 1 PC |

| Price: | Negotiable |

| Payment Terms: | T/T, Western Union, L/C, MoneyGram |

| Supply Ability: | 10,000,000 Point /Day |

| Delivery Time: | 1-7days |

| Packaging Details: | ESD packaging with carton box |

| Product name: | Multilayer PCB Assembly |

| Number of layers: | 1-46 layers |

| Surface finishing: | HASL lead free/ENIG /HASL /FINGER GOLD/IMMERSION TIN/SELECTIVE THICK GOLD |

| Copper thickness: | 0.3OZ to 6OZ |

| Min. line width/spacing: | 0.030mm ,0.03mm |

| Board thickness: | 0.3mm , 1.2mm , 1.6mm ....3.5mm |

| Min. hole size: | Laser 0.05mm ; Mechnical 0.15 |

| Solder mask color: | Blue.green.red.black.white.etc |

| Material: | FR4 /Normal Tg/High Tg/Low Dk/HF FR4/PTEE/PI |

| Pcb assembly method: | Mixed,BGA,SMT,Through-hole |

At HAINA LEAN Assembly Technology, we are capable of handling multilayer PCB assembly services with a focus on quality and reliability.

With the increasing complexity of modern electronics, the multi-layer PCBs are used more and more. The rising demanding for smaller and lighter boards, we add the popularity of multi-layer boards for use in electrical devices, military equipment, and healthcare apparatus and so on.

Multilayer PCBs becomes an essential part of modern electronics due to the host of benefits they offer. We fabricate PCBs using several lead-free components in RoHS compliant designs.

| FACTORY CAPABILITIES | |||

| No. | Items | 2019 | 2020 |

| 1 | HDI Capabilities | HDI ELIC (4+2+4) | HDI ELIC(5+2+5) |

| 2 | Max layer count | 32L | 36L |

| 3 | Board Thickness | Core thickness 0.05mm-1.5mm ,Fineshed board thickness 0.3-3.5mm | Core thickness 0.05mm-1.5mm ,Fineshed board thickness 0.3-3.5mm |

| 4 | Min.Hole Size | Laser 0.075mm | Laser 0.05mm |

| Mechnical 0.15mm | Mechnical 0.15mm | ||

| 5 | Min Line Width/Space | 0.035mm/0.035mm | 0.030mm/0.030mm |

| 6 | Copper Thickness | 1/3oz-4oz | 1/3oz-6oz |

| 7 | Size Max Panel size | 700x610mm | 700x610mm |

| 8 | Registration Accuracy | +/-0.05mm | +/-0.05mm |

| 9 | Routing Accuracy | +/-0.075mm | +/-0.05mm |

| 10 | Min.BGA PAD | 0.15mm | 0.125mm |

| 11 | Max Aspect Ratio | 10:1 | 10:1 |

| 12 | Bow and Twist | 0.50% | 0.50% |

| 13 | Impedance Control Tolerance | +/-8% | +/-5% |

| 14 | Daily Output | 3,000m2 (Max capacity of equipment) | 4,000m2 (Max capacity of equipment) |

| 15 | Surface Finishing | HASL lead free/ENIG /HASL /FINGER GOLD/IMMERSION TIN/SELECTIVE THICK GOLD | |

| 16 | Raw Material | FR-4/Normal Tg/High Tg/Low Dk/HF FR4/PTEE/PI | |

| PCBA Capability | ||||||

| Material type | PCB | Components | ||||

| Item | Dimension (Length, width,height. mm) | Material | Surface finish | Chip&IC | BGA Pitch | QFP Pitch |

| Min | 50*40*0.38 | FR-4,CEM-1,CEM-3,Aluminium-based board,Rogers,ceramic plate,FPC | HASL, OSP, Immersion gold, Flash Gold Finger | 1005 | 0.3mm | 0.3mm |

| Max | 600*400*4.2 | |||||

Our SMT capabilities:

SMT Assembly: SMT provides a flexible high technology.

These solutions include:

7 high-speed placement machines,

7 automatic printers with fiducial alignment,

2 X-ray machines,

BGA maintenance machines,

ICT test machines

Our DIP function:

A-8 semi-assembly production line with four wave soldering machines

1 U-shaped automatic assembly line for box-type building products with test stations

High temperature / low temperature aging test furnace B-4 for products required for aging test

With time control and temperature control

All products are 100% inspected and tested during the DIP process

Haina lean Electronics Co.,Ltd is a competitive China customize pcba for medical breathing machine OEM manufacturer, supplier and vendor, you can get quick turn customize pcba for medical breathing machine production prototypes and samples from our factory.

Hot Tags: customize pcba for medical breathing machine, China, supplier, manufacturer, factory, OEM manufacturer, vendor, samples, production, prototypes, quick turn

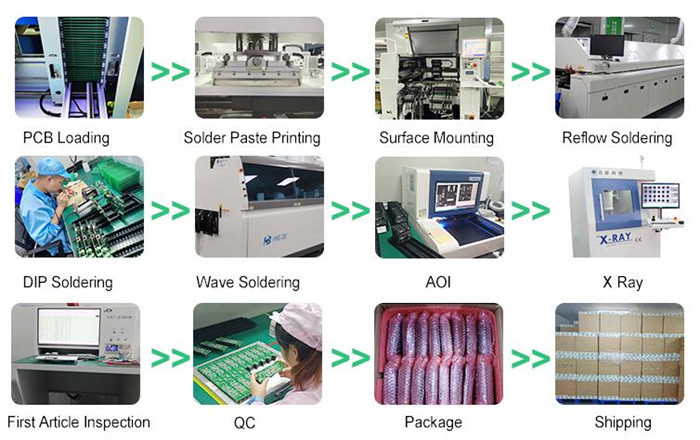

Multilayer PCB Assembly Process

1.Solder Paste stenciling---

2.Surface Mount Technology (Pick and Place)---

3.Reflow Soldering---

4.Inspection and Quality Control---

5.Through-Hole Component Insertion (DIP Process)---

6.Final Inspection and Functional Test.

1.Service value Independent quotation system to quickly serve the market | 2.PCB manufacturing High-tech PCB and PCB assembly production line |

3.Material purchasing A team of experienced electronic component procurement engineers | 4.SMT post soldering Dust-free workshop, high-end SMT patch processing |

| Product Type | Qty | Normal lead time | Quick-turn lead time |

| SMT+DIP | 1-50 | 1WD-2WD | 8H |

| SMT+DIP | 51-200 | 2WD-3WD | 1.5WD |

| SMT+DIP | 201-2000 | 3WD-4WD | 2WD |

| SMT+DIP | ≥2001 | 4WD-5WD | 3WD |

| PCBA(2-4Layer) | 1-50 | 2.5WD-3.5WD | 1WD |

| PCBA(2-4Layer) | 51-2000 | 5WD-6WD | 2.5WD |

| PCBA(2-4Layer) | ≥2001 | ≥7WD | 5WD |

| PCBA(6-10Layer) | 1-50 | 3WD-4WD | 2.5WD |

| PCBA(6-10Layer) | 51-2000 | 7WD-8WD | 6WD |

| PCBA(10-HDILayer) | 1-50 | 7WD-9WD | 5WD |

| PCBA(10-HDILayer) | 51-2000 | 9WD-11WD | 7WD |

Our advantages for your choosing:

1. Our company has passed the ts16949:2009 quality system certification, and the processed products meet the export standards of Europe and America

2. There is no minimum order quantity limit, which supports the whole process from sample to batch.

3. A professional component procurement team, centralized procurement, to save your procurement costs, labor costs, quality costs.

4. Professional sample making: SMT samples will be delivered within 24 hours.

5. Our main customer base: automotive electronics, industrial control, security, communication, power and other high-end.

Our products are widely used in communication equipment, industrial control, consumer electronics, medical equipment, aerospace, light-emitting diode lighting, automotive electronics etc

Workshop

1.PCB: Vacuum packaging with carton box

2.PCBA: ESD packaging with carton box

1.What are needed for quotation?

PCB: Quantity, Gerber file and Technic

requirements(material,surface finish treatment, copper

thickness,board thickness ......)

PCBA: PCB information, BOM, (Testing documents...)

2. What file formats do you accept for production?

Gerber file: CAM350 RS274X

PCB file: Protel 99SE, P-CAD 2001 PCB

BOM: Excel (PDF,word,txt)

3.Are my files safe?

Your files are held in complete safety and security.We protect the

intellectual property for our customers in the whole process.. All

documents from customers are never shared with any third party.

4.MOQ?

There is no MOQ .We can flexibly handle small and mass production.

5.Shipping Cost ?

The shipping cost is determined by the destination ,weight ,packing size of the goods .We can provide shipping, air, land, express and other transportation services .

6.How to ensure high-quality production?

The process is strictly controlled under ISO 9001:2015 standards.

Most of our advanced equipment and tools are imported from abroad.

Such as Flying Probe, X-ray Inspection, AOI (Automated Optical

Inspector) and ICT (in-circuit testing).

We have a very professional QC team.

Q7.What are the services you can provide ?

One-stop contract manufacturing PCB Assembly; PCB Design & Layout;

PCBA programming & functional testing; Electronic components

purchasing service; Enclosure molding & final assembly with

labels,instructions,enclosure, boxes etc.

Q8.Whether all PCBA s will be tested before delivery ?

Yes , we will test each piece of PCBA product under your testing methods ,to ensure quality and functionality .

Q9.Do you provide OEM service ?

Yes ,we offer PCB and PCBA OEM Service , we manufacture the PCB and PCBA products to your design and requirements .

Haina lean Electronics is a one-stop EMS supplier integrating PCB

design, PCB manufacturing, Component sourcing and PCB assembly.

The company is specialized in electronic products supporting

processing services, mainly to undertake circuit board design,

layout production, components procurement, PCB plate making,

circuit board welding assembly debugging and other OEM/ODM

services.

We have profuse experience in manufacturing PCB,owned experienced technical R & D technology team, young and professional sales and customer service team, experienced and professional procurement team and assembly testing team, so donot worry the products' quality of the pass rate, on-time delivery orders.

|