| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Workshop Overhead Crane |

|---|---|

| Brand Name: | Kuangyuan |

| Model Number: | KSQ |

| Certification: | CE ISO GOST |

| Place of Origin: | Henan |

| MOQ: | 1 set |

| Price: | Negotiation |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 35000 Set/Sets per Year |

| Delivery Time: | 35 working days |

| Packaging Details: | Packed by woven plastic cloth, electrical parts and other parts packaged in high quality plywood crate. But the container is also accepted if it is suitable. |

| Lifting mechanism: | European electric hoist |

| electric parts: | Siemens |

| Control Method: | Remote Control, cabin control |

| working duty: | M5 |

| span: | 5-30m |

| max lifting height: | 31m |

| Speed: | Frequency control speed |

| traveling speed: | 20m/min |

| lifting motor: | Gemerny or China |

| electric cabinet: | IP55 |

| Power Source: | 380~480V/Custmized |

| warranty: | one year |

| Company Info. |

| Henan Mine Crane Co.,Ltd. |

| View Contact Details |

| Product List |

FEM Crane KSQ 20/5 Ton Double Beam Bridge crane with Electric Winch Trolley

Product description of FEM Crane KSQ 20/5 Ton Double Beam Bridge crane with Electric Winch Trolley :

European Double girder overhead crane is composed with Girder

frame, Crane travel device, and the trolley with lifting and moving

device. There are Pave the rail for the trolley move on the main

girder.Assemble the moving table on the outside of the two main

girder, one side is prepare for the assemble and maintenance the

crane move device, another side is prepare for the assemble of the

trolley conductor device.

European Standard Electric Motor Drive Traveling Beam Overhead

Bridge Crane is designed with compact structure, small wheel

pressure, which carries out effective use of limited plant space,

and reduce the cost of plant structure.

Security of european wire rope hoist lifting equipment:

1. Reducer anti-fall, anti-lock;

2. Outdoor hoist with a rain cover;

3. Alarm indicator;

4. Infrared anti-collision.

Main Features of FEM Crane KSQ 20/5 Ton Double Beam Bridge crane

with Electric Winch Trolley:

1. Light self-weight

2.Small space use

3.Low cost of running and maintaining

4.High perormance

5.Easy to orerate

6.Safety and reliable

7.Fast and easy positioning

8.Safety monitoring system( optional)

9.PLC+ man-machine interface ( optional)

Product technical parameters

| Capacity | T | 20/5 | ||||||

| Span | m | 7.5 | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 |

| Lifting height | m | 9/12/18/24 | ||||||

| Lifting speed | m/min | 3.5(3.5/0.35) or8(8/0.8) | ||||||

| Trolley travelling speed | m/min | 20 | ||||||

| Crane travelling speed | m/min | 20 | ||||||

| Total weight | kg | 10500 | 11500 | 13640 | 15980 | 17700 | 20300 | 22920 |

| Max. Wheel load | KN | 118 | 129 | 135 | 148 | 156 | 164 | 169 |

| Rail recommended | Model | 38kg/m | ||||||

| Total motor power | kw | 19.3 | ||||||

| Main dimension (mm) | Span(m) | 7.5 | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 |

| Rail top to crane top | H | 1790 | ||||||

| Rail top to hook center | H4 | -350 | ||||||

| Crane base distance | W | 3750-4500 | ||||||

| Crane width | B | 4632-5982 | ||||||

| Trolley rail distance | K | 1600-2550 | ||||||

| Hook left limitation | S1 | 1100 | ||||||

| Hook right limitation | S2 | 1100 | ||||||

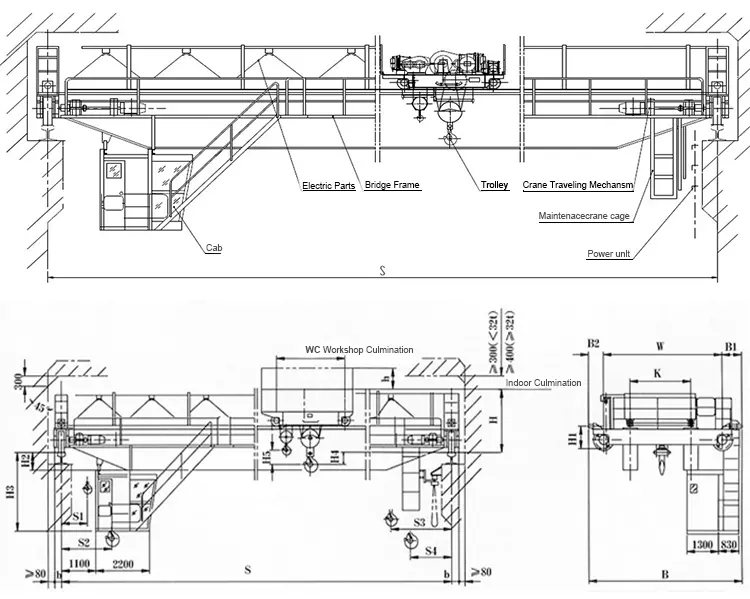

Drawing of FEM Crane KSQ 20/5 Ton Double Beam Bridge crane with

Electric Winch Trolley:

Our Advantage:

The 2,700-plus-member factory covers over 680,000 square meters and

has a total asset of RMB 660 million. The 1,200-plus equipment

enable the company to independently conduct over 20 technological

flows, including lathing, milling, planning and grinding, The

180-plus intermediate and senor technical staff are responsible for

R&D and production of all the products. The products have

passed CE SGS TUV BV and CU-TR verification, and factory passed

ISO9001-2008 international certification, IS014001:1996

environmental and ISO28001-2001 quality, health and safety

certification. Our company has perfect quality-control system,

strict and comprehensive management system, strong production

capability and advanced test measures, guaranteeing high quality,

output, competitiveness and market share.

|