| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Vertical Cardboard Baler |

|---|---|

| Brand Name: | Hh |

| Model Number: | 10-100T |

| Certification: | CE |

| Place of Origin: | CHINA |

| MOQ: | 1 |

| Price: | negotiated |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 100 sets every month |

| Delivery Time: | 5-8 days |

| Packaging Details: | plastic |

| function: | carton machinery spare part |

| condition: | new |

| type: | caron machine spare parts |

| After-sales service provided: | video technical support |

| Packaging type: | cartons |

| Product name: | Corrugated Machine Parts Circular Slitting Knives, stacker, slotter knife, China semi-auto parts rotary die cutting machinery for sale, Automatic short run cardboard box making machine |

| Marketing Type:: | Ordinary Product |

| Package: | Plastic Box Wood Carton |

| Usage: | corrugated paper cutting Arc-shaped slotter knife |

| Company Info. |

| Dongguang Haohan International Trade Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

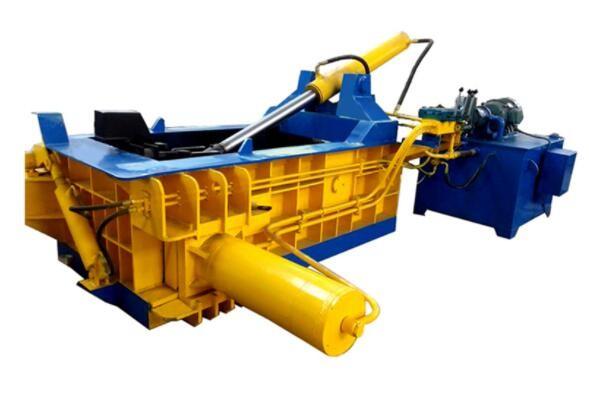

Cardboard Baler Press Scrap Kraft Paper Waste Baler Machine

Waste Scrap Kraft Paper Waste Baler Machine / Waste Cardboard Baler press machine / Scrap is suitable for the steel plants, recycling companies, ferrous & non-ferrous metal smelting industry to compress metal scrap (steel parings, waste steel, waste copper & aluminum, waste stainless steel, scrap from discarded automobiles) into acceptable furnace charges of cuboids, cylinders, octagons & other shapes, so as to reduce the cost of transportation & smelting, to speed up furnace charging.

Specification

| Nominal force (kN) | 1600 |

| Dimension of compress room (L*W*H)(mm) | 1600*1000*800 |

| Bale dimension (L*W*H)(mm) | (400-600)*350*350 |

| (400-600)*400*400 | |

| Bale density (kg/m3 ) | >1800 |

| Capacity (kg/h) | 2000-3000 |

| Single cycle time(s) | <150 |

| Power (kW) | 30 |

| Bale discharging and operation | Turn-out, hand valve control |

Features

1 Such machineries adopt hydraulic drive ,with manual or PLC automatic control operation as options .

2 The hydraulic system applies an integrated valve block and the product is stable and reliable in technical performance.

3 The discharging types fall into turning over ,push out ,forward out and manual lifting .

4 It is unnecessary to fix foot screw and a diesel engine can be used in case of power supply unavailability .

5 The extrusion force ranges from 63t to 400t ,totaling 10 grades for customers’ selection ,and productivity being from 4t/shift to 40t/shift .

6 The size of the compression chamber and the form and size of the bale can be designed and customized according to the requirement of the customers .

|