| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Downspout Pipe Roll Forming Machine |

|---|---|

| Brand Name: | Gracias |

| Model Number: | YH36 pipe forming machine |

| Certification: | CE |

| Place of Origin: | China |

| MOQ: | 1set |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 60sets per month |

| Delivery Time: | 60-90 work days |

| Packaging Details: | as costomer's request,40GP*2 |

| Voltage: | 3P,380V,50HZ |

| Use: | Weld pipe |

| Warranty: | One Year |

| Speed: | 20-50m/minute |

| Pipe diameter: | customized |

| Pipe material: | Carbon Steel,Alloy Steel,Hot or Cold steel strip |

| Dimension(l*w*h): | according order |

| After-sales service provided: | Video technical support |

| Company Info. |

| WENZHOU YIHENG MACHINERY CO.,LTD |

| View Contact Details |

| Product List |

CE Downpipe Roll Forming Machine 50m/min High Frequency Welded

Introduction of the component:

Uncoiler

Briefing: Rotary type to change coils easily with a pneumatic brake

Parameters:

| the max.weight of coil | 3000KG |

| the inside diameter of coil | 450-520mm |

| the max.outside diameter of coil | 1600mm |

| the max.width of coil | 400mm |

Computer-controlled flying saw

| Power of automatic controller | 18.5KW |

| Max cutting diameter | 90mm |

| The range of cutting length | 4m-7m |

| Max cutting thickness | 4mm |

| Type:metal saw disc | 600*70*2.5mm |

| Power of the saw | 22KW |

| Accuracy of the cutting length | within + 0.3mm |

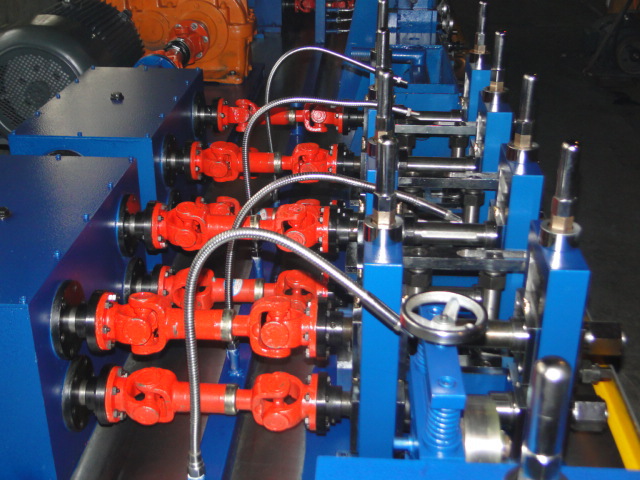

Forming Machine

| vertical rollers | 7 steps |

| the diameter of the vertical shaft | 60mm |

| the material of the shaft | 40Gr |

| horizontal rollers | 8 steps |

| the diameter of the horizontal shafts | 40mm |

| the material of the rollers | Gr12 |

| the vertical stand | 45#steel,heat treated HRC 60-64 |

| the horizontal stand | forge steel |

| guide shafts | adjust the welding line |

| cooling box | welding sheet,the length confirmed according to the machine and pipe |

| the speed | 30-90m/min |

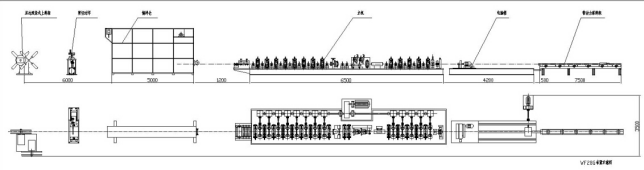

Process flow:

Double-head uncoiler---Coil cutting and welding together----Accumulator---Flatting---Roundpipe forming

---cooling---Square pipe forming----sizing---fly saw cutting---run out table

Main Drive

A,the main motor Z4-225-11,110KW DC motor Z4-225-11,110kw

B,speed reducer model ZLY200,the ratio is16:1 ZLY200 16:1

C,drag device EURO DC control device

Butt welding machine

A,width:<400mm

B,thicknesss:<3.0mm

Accumulator

A,material:made of angle and channel iron

B,feeding speed: above 150m/min

C,collecting capacity:< 2000kg

Width Adjustment

Range:94-290mm

Accumulating Roller

A,Material:GCr15

B,Feeding rollers:150mm,2 pcs

C,Motor:5.5KW,6 Classes,1 set

Sizing parts

A,vertical shaft: 6 steps

B,the diameter of the shaft:60mm

C,the material of the shaft:40Gr

D,the horizontal shaft:6 steps

E,the diameter of the shaft:40mm

F,the material of the rollers:Gr12

G,the usage: make the round pipe in strictly round, form the square pipe and make the square in strictly square.

H,the horizontal stand:forge steel

I,Turk’s head:use for flatting

J,the speed:30-90m/min.

K,two sets molds: one for 15*15mm ,the other is for 45*45mm.

4.10 Run out table

Automatic rail type run out table

4.11High-frequency

A,Model:GP150-0.4

B,input power:3P,380V,50HZ

C,output power:150KW

D,control mode of output power:regulated by microprocessor

E,output frequency:350-420KHZ

|