| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | MoSi2 Heating Elements |

|---|---|

| Brand Name: | ZG |

| Model Number: | MS |

| Certification: | CE |

| Place of Origin: | CN |

| MOQ: | 1 piece |

| Price: | USD10/piece |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 10000 pieces per month |

| Delivery Time: | 3 working days |

| Packaging Details: | Strong wooden box for Global shipping |

| MAX TEMPERATURE:: | 1700°C / 1800°C |

| DIAMETER:: | 3/6, 4/9, 6/12, 7/12, 9/18, 12/24mm |

| COOLING ZONE LENGTH:: | 80 - 1500mm |

| SHAPE:: | Special Shape |

| HEATING ZONE LENGTH:: | 80 - 1500mm |

| MOLYBDENUM PURITY:: | 99.9% High Purity |

| Company Info. |

| HENAN ZG INDUSTRIAL PRODUCTS CO.,LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

High Purity Mosi2 Heating Elements, 1700 °C / 1800 °C Moly Disilicide Heating Elements Rod

Application:

Widely used in research and production of glass, ceramic, refractory, metallurgy, steel-making, crystal, electronic parts, semiconductor material. The MoSi2 Heating Elements model including BR1700 (working temperature 1600℃) and BR1800 (working temperature 1700℃)

MoSi2 Heating Elements Features:

MoSi2 Heating Elements Properties

1.Physical properties

| Density | Bending strength | Hardness | Porosity | Water absorption | Thermal elongation | Fracture toughness | Compression strength |

| 5.8g/cm3 | 350MPa | 12.0GPa | +/-5% | 0.6 | 4% | 4.5MPa.m1/2 | 650MPa |

2.Chemical properties:

High temperature antioxidant property:

At a high temperature oxidizing atmosphere, a dense quartz SiO2

protect layer will be generated in the surface of the hot zone to

prevent the element from further oxidation. When the temperature is

higher than 1700C, the protection layer would be melt. Due to the

effect of surface tension, quartz agglomerating into drops, and

loses the protection. Then continue to use in the oxidizing

atmosphere, the quartz protection layer again generate.

Note: the element can’t be used for a long time in the temperature range of 400C to 700C, otherwise it will be strongly oxidated and damaged

3.The influence of the different atmosphere

| Atmosphere | Max element temperature | |

| 1700 type | 1800 type | |

| Air | 1700C | 1800C |

| He Ar Ne | 1650C | 1750C |

| SO2 | 1600C | 1700C |

| CO N2 | 1500C | 1600C |

| (Wet) H2 | 1400C | 1500C |

| (Dry) H2 | 1350C | 1450C |

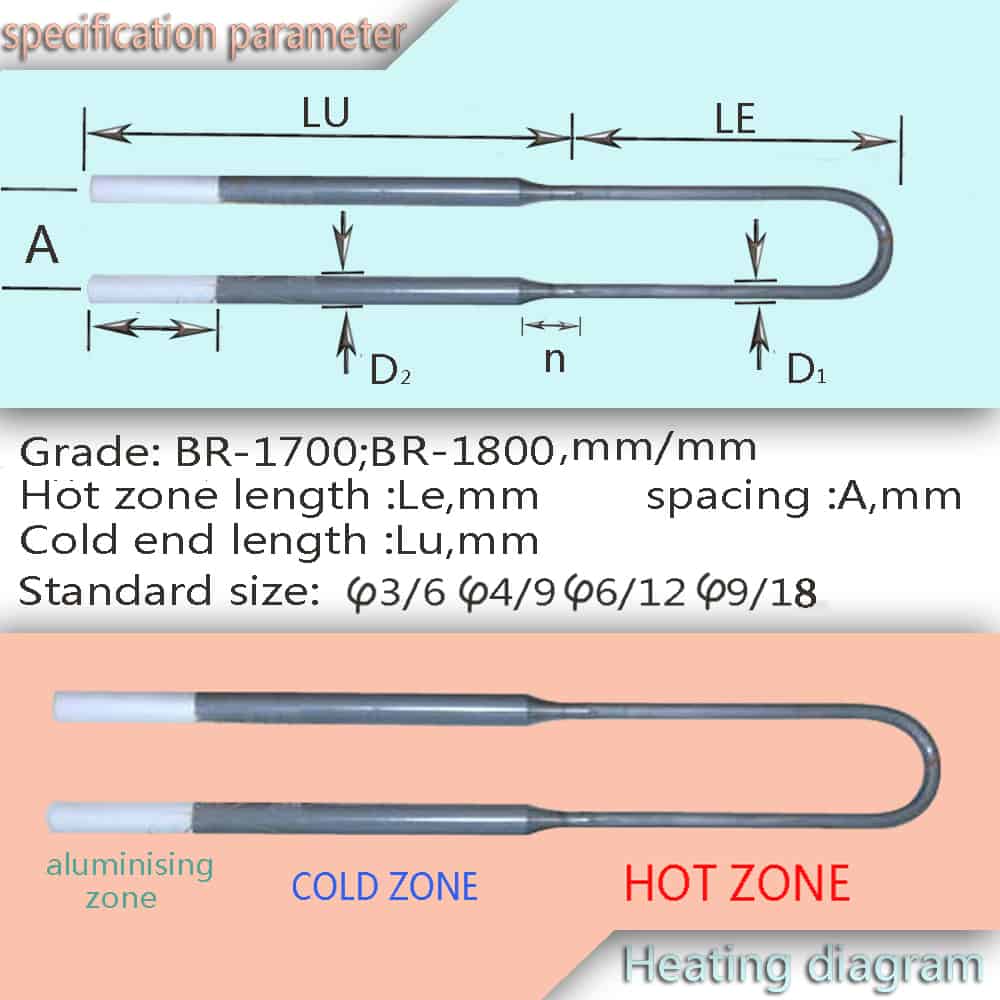

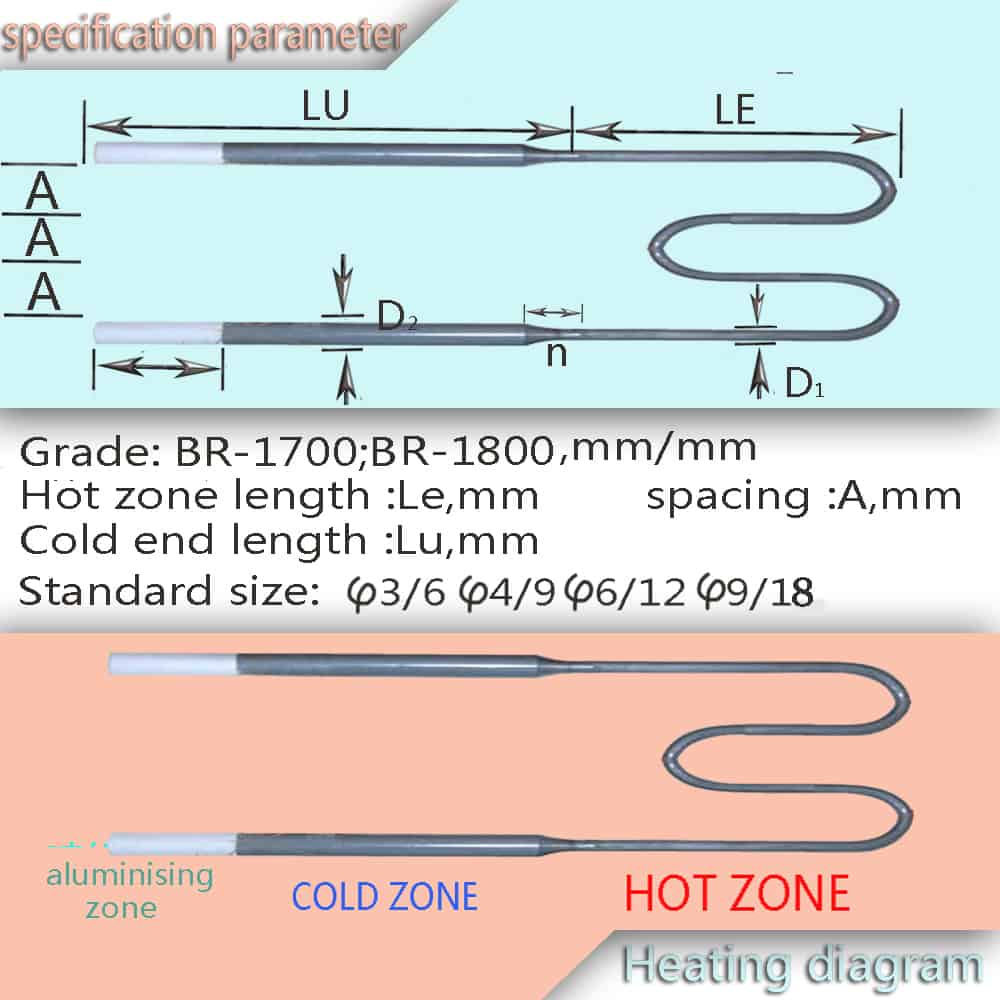

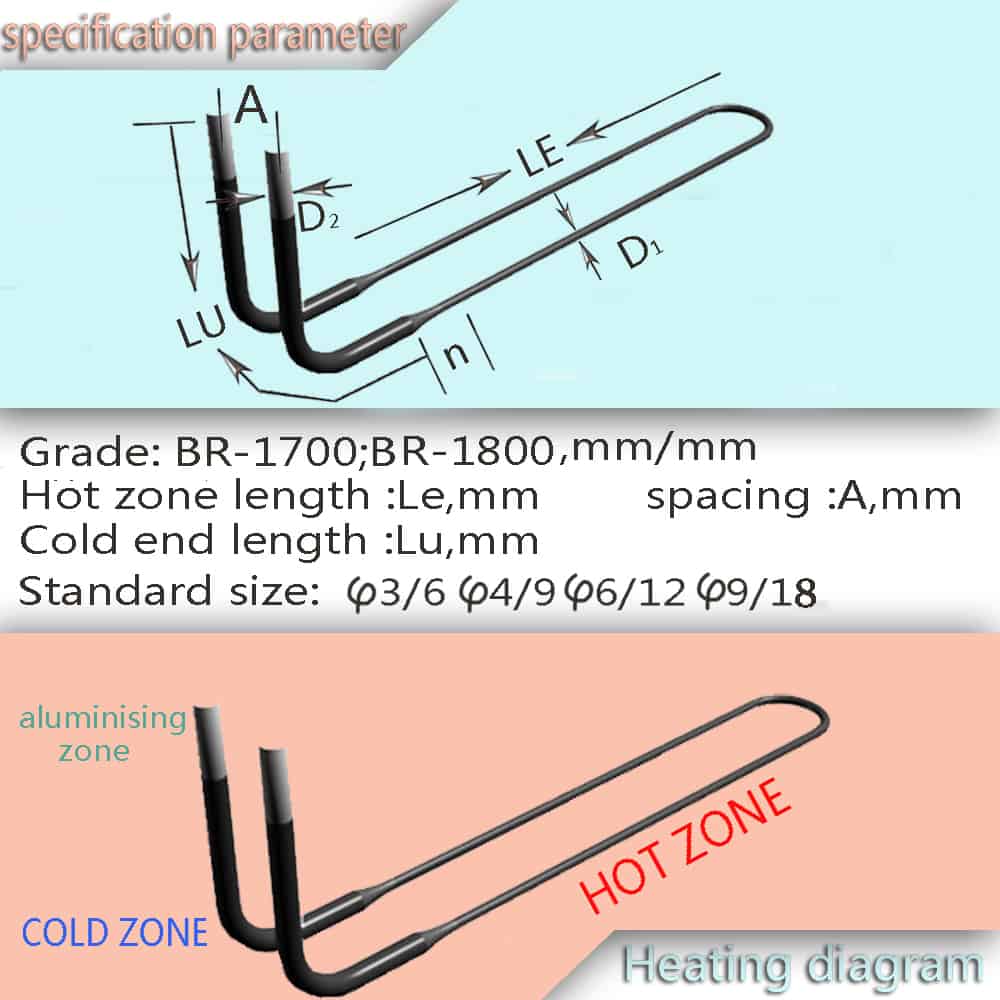

| Heating zone dia. D1 | Cooling zone dia. D2 | Heating zone length Le | Cooling zone length Lu | Central distance A |

| 3mm | 6mm | 80-300mm | 80-500mm | 25mm |

| 4mm | 9mm | 80-350mm | 80-500mm | 25mm |

| 6mm | 12mm | 80-800mm | 80-1000mm | 25-60mm |

| 7mm | 12mm | 80-800mm | 80-1000mm | 25-60mm |

| 9mm | 18mm | 100-1200mm | 100-2500mm | 40-80mm |

| 12mm | 24mm | 100-1500mm | 100-1500mm | 40-100mm |

| Note: 1.Special size is customizable. 2.Delivery time only need 3 days for normal size | ||||

| Model: ZG1700 (working temperature 1600℃) and ZG1800(working temperature 1700℃) | ||||

1. Type (U, W, L)

2. Diameter: D1, D2

3. Heating zone length: Le

4. Cooling zone length: Lu

5. The distance between two terminals: A

|