| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | Multilayer PCB Assembly |

|---|---|

| Brand Name: | HNL-PCBA |

| Model Number: | PCB Assembly 010 |

| Certification: | ISO9001,IS16949, ISO14001,ROHS ,UL, IPC-A ,QC080000 |

| Place of Origin: | CHINA |

| MOQ: | 1 PC |

| Price: | Negotiable |

| Payment Terms: | T/T, Western Union, L/C, MoneyGram |

| Supply Ability: | 10,000,000 Point /Day |

| Delivery Time: | 1-7days |

| Packaging Details: | ESD packaging with carton box |

| Product name: | 4 layers Multilayer PCB Assembly |

| Material: | FR-4 |

| Surface finishing: | HASL,OSP,ENIG,HASL Lead Free,Immersion Gold |

| Copper thickness: | 1OZ |

| Min. line width/spacing: | 4/4mil |

| Board thickness: | 1.6mm |

| Min. hole size: | Laser 0.05mm;Mechnical 0.15mm |

| Pcb assembly methods: | Mixed,BGA,SMT,Through-hole etc. |

| Solder mask: | orange,green/black/white/red/blue etc. |

| Item: | ODM OEM PCBA,pcb assembly,2 Layer Pcb |

Multilayer PCB Assembly Introduction

Multilayer PCB Assembly can save your money, have shorter lead time, and is of high-quality products. Our assemblers, preparing the PCB boards, procure raw materials & components, finishing quality testing & inspection, assembly it ready for delivery finally.

Our professional team are experienced in handling this delicate process, aiming to build multifunctional assemblies that serve all your purposes with space limitations to meet your needs.

| FACTORY CAPABILITIES | |||

| No. | Items | 2020 | |

| 1 | HDI Capabilities | HDI ELIC(5+2+5) | |

| 2 | Max layer count | 46L | |

| 3 | Board Thickness | Core thickness 0.05mm-1.5mm ,Fineshed board thickness 0.3-3.5mm | |

| 4 | Min.Hole Size | Laser 0.05mm | |

| Mechnical 0.15 | |||

| 5 | Min Line Width/Space | 0.030mm/0.030mm | |

| 6 | Copper Thickness | 1/3oz-6oz | |

| 7 | Size Max Panel size | 700x610mm | |

| 8 | Registration Accuracy | +/-0.05mm | |

| 9 | Routing Accuracy | +/-0.05mm | |

| 10 | Min.BGA PAD | 0.125mm | |

| 11 | Max Aspect Ratio | 10:01 | |

| 12 | Bow and Twist | 0.50% | |

| 13 | Impedance Control Tolerance | +/-5% | |

| 14 | Daily output | 4,000m2 (Max capacity of equipment) | |

| 15 | Surface Finishing | HASL Lead Free /ENEPING /ENIG /HASL /FINGER GOLD/IMMERSION TIN/SELECTIVE THICK GOLD | |

| 16 | Raw Material | FR-4/Normal Tg/High Tg/Low Dk/HF FR4/PTEE/PI | |

| PCBA Capability | |||

| Material Type | Item | Min | Max |

| PCB | Dimension (length,width,height.mm) | 50*40*0.38 | 600*400*4.2 |

| Material | FR-4,CEM-1,CEM-3,Aluminium-based board,Rogers,ceramic plate,FPC | ||

| Surface finish | HASL,OSP,Immersion gold,Flash Gold Finger | ||

| Components | Chip&IC | 1005 | 55mm |

| BGA Pitch | 0.3mm | - | |

| QFP Pitch | 0.3mm | - | |

SMT capabilities:

SMT Assembly: SMT provides a flexible high technology.

These solutions include:

7 high-speed placement machines, 7 automatic printers with fiducial alignment, 2 X-ray machines, BGA maintenance machines, ICT test machines

DIP function:

A-8 semi-assembly production line with four wave soldering machines

1 U-shaped automatic assembly line for box-type building products with test stations

High temperature / low temperature aging test furnace B-4 for products required for aging test

With time control and temperature control

All products are 100% inspected and tested during the DIP process

Haina lean Electronics Co.,Ltd is a competitive China customize pcba for medical breathing machine OEM manufacturer, supplier and vendor, you can get quick turn customize pcba for medical breathing machine production prototypes and samples from our factory.

Hot Tags: customize pcba for medical breathing machine, China, supplier, manufacturer, factory, OEM manufacturer, vendor, samples, production, prototypes, quick turn

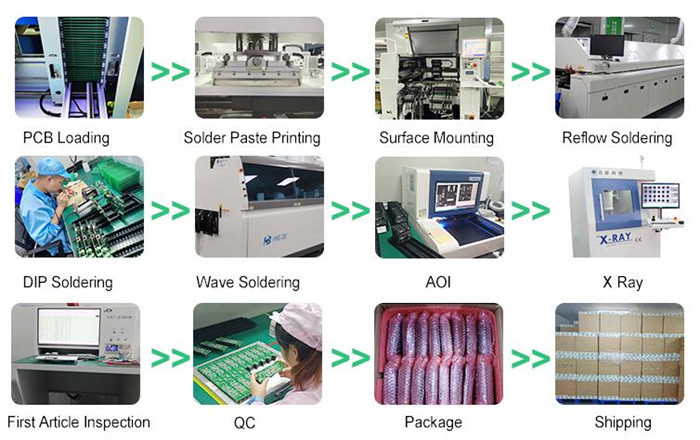

Multilayer PCB Assembly Process

1.Solder Paste stenciling

2.Surface Mount Technology (Pick and Place)

3.Reflow Soldering

4.Inspection and Quality Control

5.Through-Hole Component Insertion (DIP Process)

6.Final Inspection and Functional Test

Service value

Independent quotation system to quickly serve the market

PCB manufacturing

High-tech PCB and PCB assembly production line

Material purchasing

A team of experienced electronic component procurement engineers

SMT post soldering

Dust-free workshop, high-end SMT patch processing

| Product Type | Qty | Normal lead time | Quick-turn lead time |

| SMT+DIP | 1-50 | 1WD-2WD | 8H |

| SMT+DIP | 51-200 | 2WD-3WD | 1.5WD |

| SMT+DIP | 201-2000 | 3WD-4WD | 2WD |

| SMT+DIP | ≥2001 | 4WD-5WD | 3WD |

| PCBA(2-4Layer) | 1-50 | 2.5WD-3.5WD | 1WD |

| PCBA(2-4Layer) | 51-2000 | 5WD-6WD | 2.5WD |

| PCBA(2-4Layer) | ≥2001 | ≥7WD | 5WD |

| PCBA(6-10Layer) | 1-50 | 3WD-4WD | 2.5WD |

| PCBA(6-10Layer) | 51-2000 | 7WD-8WD | 6WD |

| PCBA(10-HDILayer) | 1-50 | 7WD-9WD | 5WD |

| PCBA(10-HDILayer) | 51-2000 | 9WD-11WD | 7WD |

Workshop

PCB: Vacuum packaging with carton box

PCBA: ESD packaging with carton box

|