| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

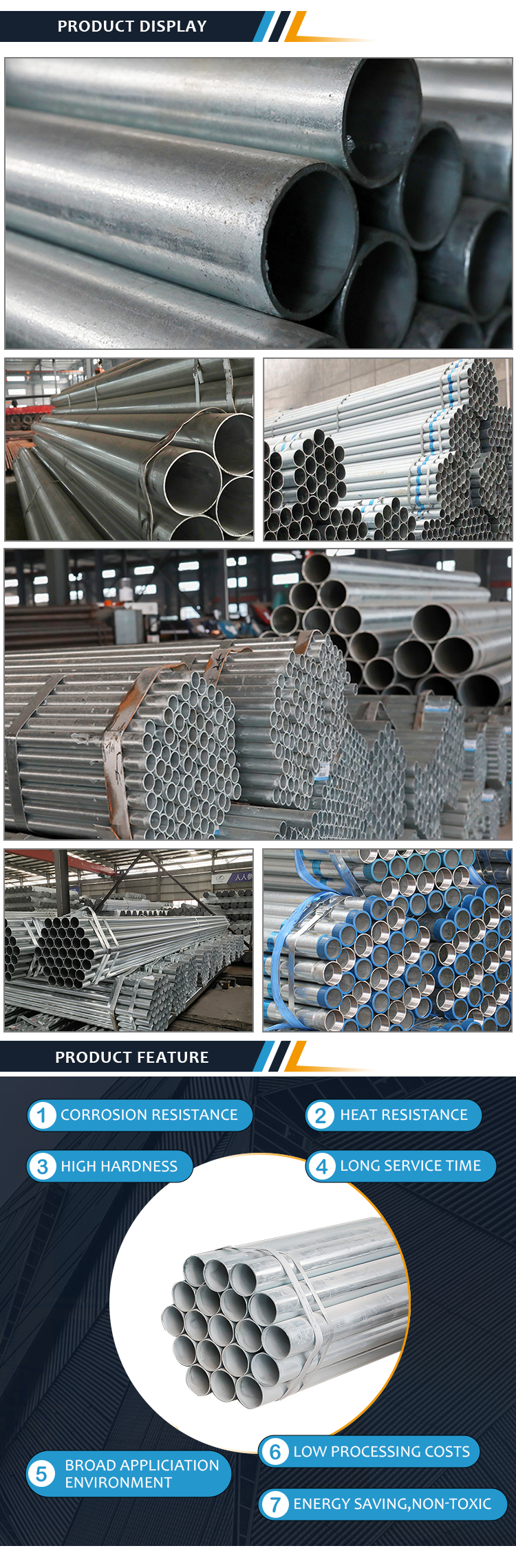

| Categories | Galvanized Steel Tube |

|---|---|

| Brand Name: | NADONG |

| Model Number: | 316 |

| Certification: | ISG SGS |

| Place of Origin: | CHINA |

| MOQ: | 1 Ton |

| Price: | $450-$800 |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1000 ton per month |

| Delivery Time: | 15 working days |

| Packaging Details: | According to customer needs |

| Grade: | A53 |

| Technology: | Hot Rolled Cold Rolled |

| Tolerance: | ±1% |

| Oiled or Non-oiled: | Slightly Oiled |

| Surface Treatment: | galvanized |

| Surface: | Polishing,annealing,pickling,bright |

| Shape sections: | Round, Square, Rectangular |

| Payment terms: | TT , LC |

The hot-dip galvanized pipe is to make the molten metal and the iron matrix react to produce an alloy layer, so that the matrix and the coating are combined. Hot-dip galvanizing is to pickle the steel pipe first. In order to remove the iron oxide on the surface of the steel pipe, after the pickling, it is cleaned in a tank of ammonium chloride or zinc chloride aqueous solution or a mixed aqueous solution of ammonium chloride and zinc chloride, and then sent to In the hot dip plating tank. |

Chemical Composition

| Specification | Grade | Chemical Composition(wt%) | ||||||

| C | Mn | Ni | Cr | Mo | Ti | |||

| ASTMJIS | 316L/022Cr17Ni12Mo2 | ≤0.03 | ≤2.0 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | - | |

| JIS | SUS316L | ≤0.03 | ≤2.0 | 12.0-15.0 | 16.0-18.0 | 2.0-3.0 | - | |

| ASTMJIS | 316Ti/SUS 316Ti | ≤0.08 | ≤2.0 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | 5*(C+N)-0.7 | |

Properties

| Spec | Grade | Mechanical Property | Physical Property | ||||

Y.S (N/MM2) | T.S (N/MM2) | EL (%) | HRB | Specific Heat (J/g℃) | Modulus of Elasticity (KN/mm2) | ||

| ASTM/GB | 316L/022Cr17Ni12Mo2 | ≥170 | ≥485 | ≥40 | ≤95 | 0.5 | 193 |

| JIS | SUS316L | ≥175 | ≥480 | ≥40 | ≤90 | 193 | |

| ASTM | 316Ti | ≥205 | ≥515 | ≥40 | ≤95 | 0.5 | 200 |

Applications:316L: Widely used in corrosion-susceptible environment and some mechanical components those are difficult to make heat treatment after forming in more corrosive environment.316Ti: Mainly used for industrial components. |

|