| Sign In | Join Free | My carsrow.com |

|

| Sign In | Join Free | My carsrow.com |

|

| Categories | High Pressure Filter Housing |

|---|---|

| Brand Name: | SFFILTECH |

| Certification: | CE |

| Place of Origin: | China |

| MOQ: | 1 set |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 100000pcs per month |

| Delivery Time: | 20-30 days |

| Packaging Details: | wooden case |

| Name: | Waste bag multi high pressure water filter housing |

| Flow rate: | 80~800m3/h |

| Filtration Area: | 1-10m2 |

| Material: | SS304,316L,carbon steel, etc |

| Pressure: | 0.6~1.6MPa |

| Bag: | 2-20 |

| Company Info. |

| Shanghai Sffiltech Co., Ltd |

| View Contact Details |

| Product List |

Waste bag multi high pressure water filter housing

Multi Bag Filter Housing

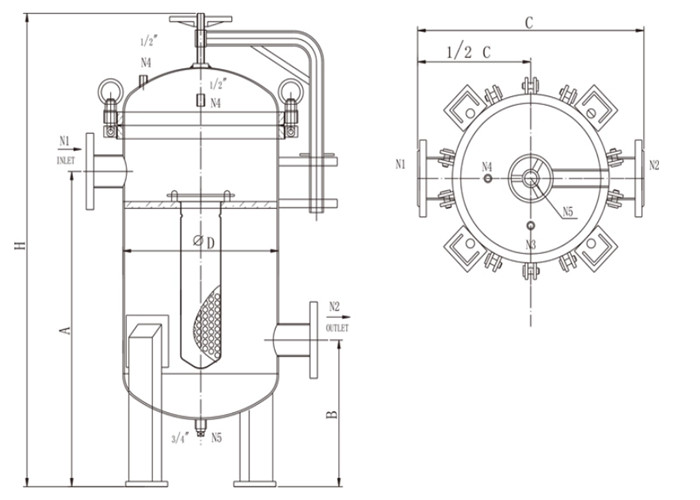

Filter body is mainly composed of three parts:the filter

container,supporting basket and the filter bag,filter process.

Replace or clean the filter bag,just loosen the ring bolt,rotating

the hand-wheel lifting cover,can be removed.

Multi bag filter has the characteristics of large capacity,large

amount of contamination,obvious filtration effect,simple

poeration,low cost operation.

High pressure water filter housing Applications

Widely used in chemical industry,industrial

wastewater,microelectronics,power plants,textile

dyes,papermaking,water prefabricated,paint and ink,food and

beverage,cosmetics,chemicals,petroleum products,electroplating,hot

solvent,emulsion,ultrasonic cleaning machine,high pressure cleaning

machine,industrial water,paint,ink,wax and other industry pre

filter or filter.

High pressure water filter housing Features

Can be customized for import and export:

side in side out,side in bottom out,bottom in and out, etc.

Filtration precision:1um-1000um optional.

The design flow can meet the requirements of 50~1000m3/h.

The material of SS304,316L,carbon steel, etc.

High pressure water filter housing selection data sheet

| Model | Bag | Filtration Area m2 | D | A | B | C | H | N1/N2 | Maximum flow (m3/H) | Pressure (Mpa) |

| QH02P2S | 2 | 1 | Ø400 | 1100 | 420 | 650 | 1600 | DN80 | 80 | 0.6~1.6 |

| QH03P2S | 3 | 1.5 | Ø450 | 1100 | 420 | 700 | 1600 | DN100 | 120 | 0.6~1.6 |

| QH04P2S | 4 | 2 | Ø500 | 1100 | 420 | 750 | 1650 | DN125 | 160 | 0.6~1.6 |

| QH05P2S | 5 | 2.5 | Ø550 | 1150 | 450 | 800 | 1700 | DN150 | 250 | 0.6~1.6 |

| QH06P2S | 6 | 3 | Ø600 | 1150 | 450 | 2000 | 1700 | DN150 | 240 | 0.6~1.6 |

| QH07P2S | 7 | 3.5 | Ø650 | 1250 | 500 | 2200 | 1750 | DN200 | 280 | 0.6~1.6 |

| QH08P2S | 8 | 4 | Ø700 | 1250 | 500 | 2230 | 1750 | DN200 | 320 | 0.6~1.6 |

| QH10P2S | 10 | 5 | Ø800 | 1250 | 600 | 2470 | 1800 | DN250 | 360 | 0.6~1.6 |

| QH12P2S | 12 | 6 | Ø850 | 1810 | 600 | 2500 | 1800 | DN250 | 480 | 0.6~1.6 |

| QH14P2S | 14 | 7 | Ø900 | 1320 | 650 | 1200 | 1850 | DN300 | 560 | 0.6~1.6 |

| QH16P2S | 16 | 8 | Ø1000 | 1320 | 650 | 1300 | 1850 | DN300 | 640 | 0.6~1.6 |

| QH20P2S | 20 | 10 | Ø1100 | 1350 | 650 | 1400 | 1900 | DN350 | 800 | 0.6~1.6 |

Table number number of the container bag to put up the bag limit,

single machine can be 50 above the bag.

The theoretical flow refers to the maximum flow bag initial surface

area.

|